Partially calcined limestone for rapid slagging of converter and preparation method thereof

A technology for calcining limestone and limestone, which is applied in the field of slag making in the converter steelmaking process. It can solve the problems of low furnace temperature, influence, and excessive limestone addition, so as to reduce energy consumption and CO2 emissions, speed up the dissolution rate, The effect of increasing the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

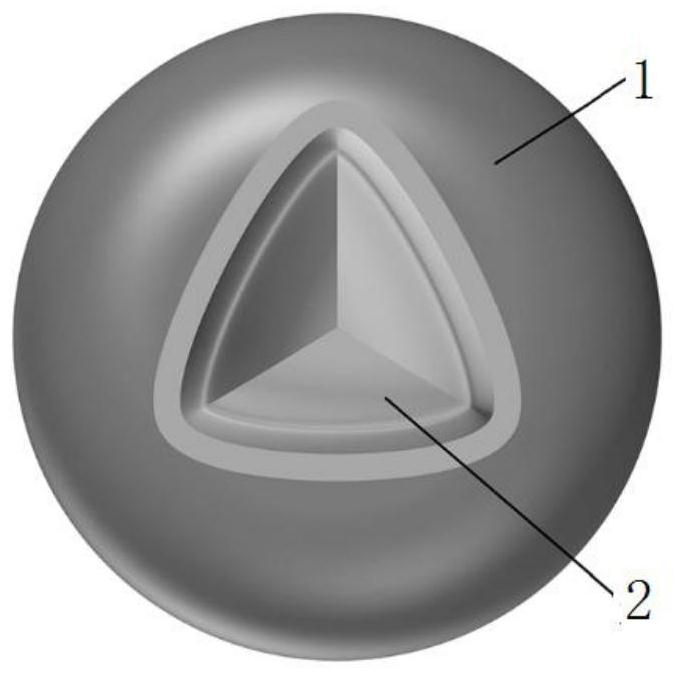

[0028] Embodiment 1: The present invention provides a kind of part calcined limestone for fast slagging of converter, its structure and physical properties are as follows figure 1 , 2 , as shown in 3, figure 1 Schematic diagram of the structure of partially calcined limestone. It can be seen from the figure that the limestone raw material has been partially calcined, and the limestone surface has been decomposed into the surface lime layer 1, which is composed of porous activated calcium oxide, and the inner core is still unreacted nuclear limestone 2, which is composed of calcium carbonate.

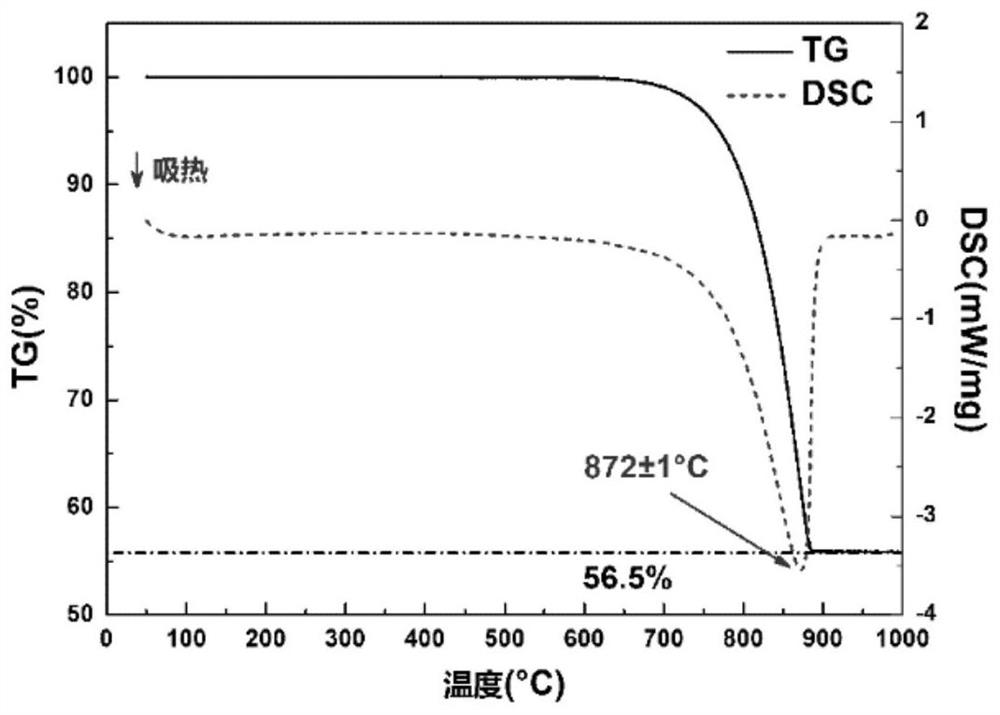

[0029] figure 2 It is the TG-DSC curve of raw limestone. It can be seen from the figure that the weight loss of raw materials after calcination can reach 43.5wt%, and the mass percentage of calcium carbonate in the raw materials can be calculated to be above 98.8.

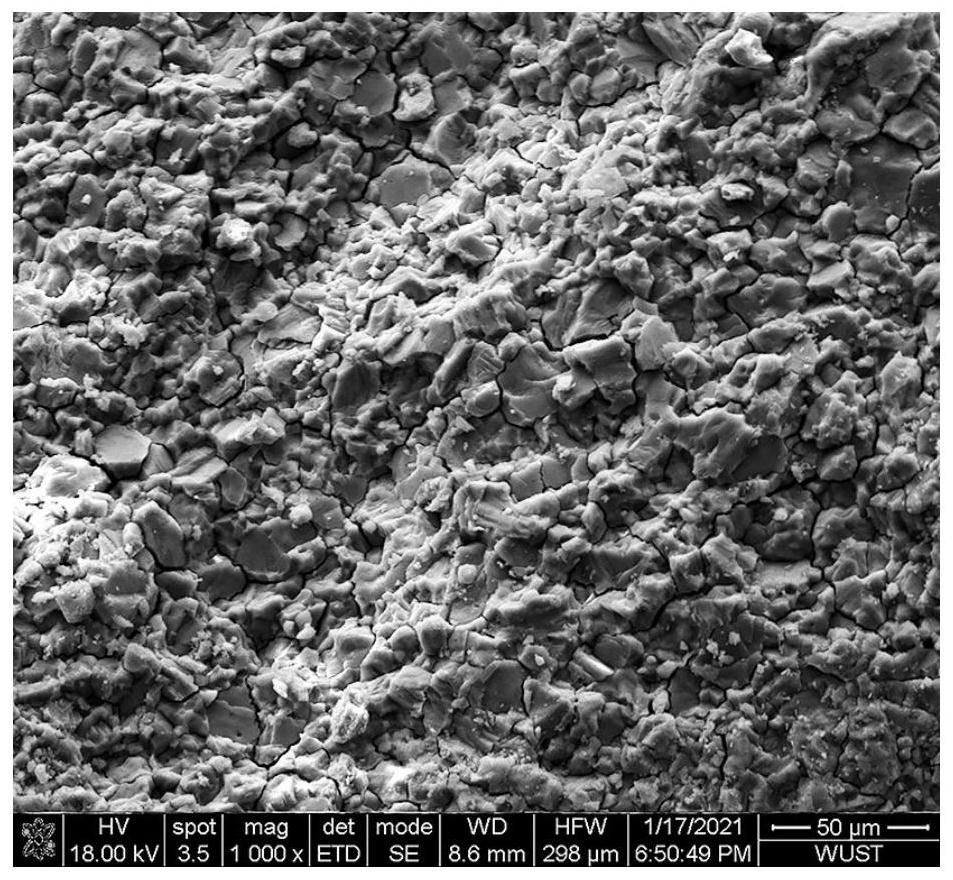

[0030] image 3 The SEM image near the surface of part of the calcined limestone is given. It can be seen from the fi...

Embodiment 2

[0040] Example 2: The present invention provides a partially calcined limestone for rapid slagging in a converter and its preparation method. The structure, preparation method and effect of using the partially calcined limestone on a converter are basically the same as in Example 1, except for the third preparation step Put the block limestone pretreated in the heating furnace, and heat it at 300°C for 2 hours to preheat to remove moisture. In the preparation step 4, put the limestone after removing moisture into the 900°C rotary kiln for 0.5h, and the rotary kiln The rotation speed of the furnace is controlled at 6 rev / min to obtain partially calcined limestone.

Embodiment 3

[0041] Example 3: The present invention provides a partially calcined limestone for quick slagging in a converter and its preparation method. The structure, preparation method and effect of using the partially calcined limestone on a converter are basically the same as in Example 1, the only difference is in the preparation step In step 4, put the limestone after dehydration into a rotary kiln at 840°C for 0.7h, and control the rotational speed of the rotary kiln at 4 rpm to obtain partially calcined limestone.

[0042] The partially calcined limestone for fast slagging in converter and the preparation method thereof of the present invention are simple and easy to operate, the surface lime layer of the prepared partially calcined limestone is highly active lime, and the core component of the inner layer is still unreacted nuclear limestone, i.e. carbonic acid calcium. Using the partially calcined limestone of the present invention to make slag in the converter, the dissolution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com