Method for improving purity of chloroacetaldehyde dimethyl acetal by vinyl acetate method

A vinyl acetate-method chloroacetal dimethyl acetal and chloroacetal dimethyl acetal technology are applied in chemical instruments and methods, preparation of organic compounds, compounds of Group 5/15 elements of the periodic table, etc. Difficult to separate, difficult to meet medical requirements, low quality of chloroacetal dimethyl acetal, etc., to achieve the effect of high efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

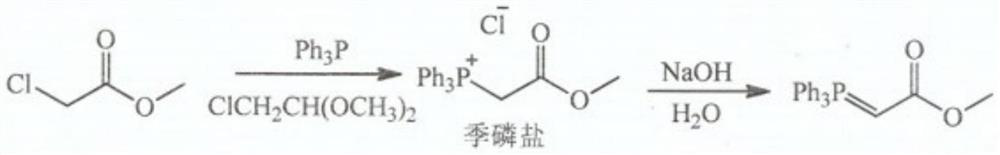

[0017] 1. Add 8 kg of chloroacetaldehyde dimethyl acetal containing 2.2% methyl chloroacetate (equivalent to 176g / 108.52=1.62mol), 1Kg of triphenyl Phosphine (3.81mol), heated to 80°C with stirring until the methyl chloroacetate content was lower than 0.1%, and the reaction time was about 8 hours.

[0018] 2. Change the reaction device into a vacuum distillation device, and distill about 7Kg of chloroacetaldehyde dimethyl acetal under the conditions of 0.095Mpa and 70°C, with a gas phase purity of 99.6%. The remaining liquid was naturally cooled to room temperature, and the white solid generated by suction filtration under reduced pressure was rinsed with 500 g of chloroacetaldehyde dimethyl acetal containing 2.2% methyl chloroacetate, and dried naturally to obtain 561 g of quaternary phosphorus salt (FW370.81). 152-153°C.

Embodiment 2

[0020] In the above-mentioned embodiment one, filter the filtrate of the quaternary phosphorus salt, add 7.5Kg of chloroacetaldehyde dimethyl acetal containing 2.2% methyl chloroacetate, 550g triphenylphosphine, repeat the operation of the first and second steps of the above-mentioned embodiment one , 7.8Kg of chloroacetaldehyde dimethyl acetal with a purity of 99.6%, 570g of quaternary phosphorus salt, and a melting point of 152-153°C can be obtained.

Embodiment 3

[0022] 1. Add 742g of the quaternary phosphorus salt obtained in the above-mentioned Example 1 into a 5L three-necked bottle with a mechanical stirrer, a thermometer, and a dropping funnel, add 2L of water and 200g of methanol to dissolve, control the temperature at 5-10°C, and add 10% dropwise NaOH solution 820g.

[0023] 2. Filtrate the resulting white solid, rinse with 100mL distilled water, and dry naturally to obtain 650g of methoxyformylmethylene triphenylphosphine, with a yield of 97%, melting point: 170-172°C, and a liquid chromatography purity of 98.5% .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com