System and method for preventing burning explosion in methyl nitrite preparation process

A technology of methyl nitrite and preparation process is applied in the field of systems for preventing combustion and explosion, and achieves the effects of preventing combustion and explosion, ensuring mixing and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

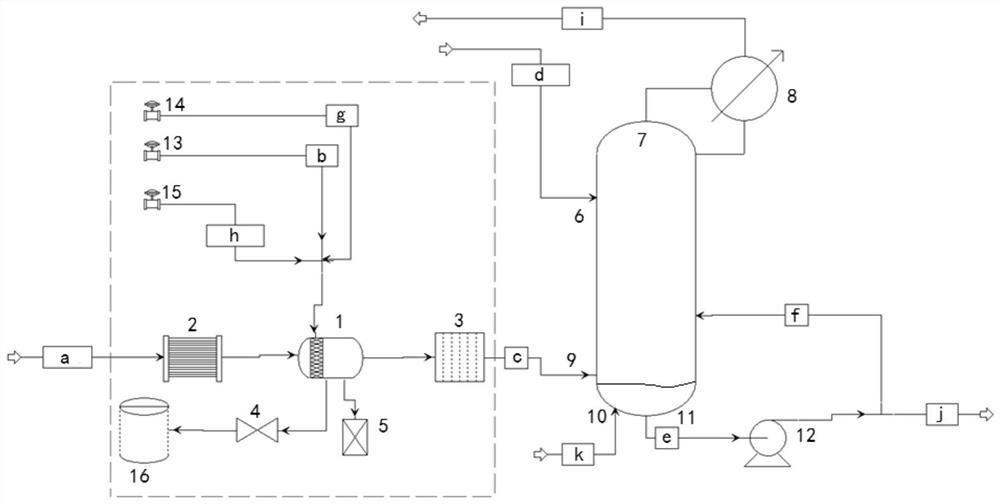

[0034] Such as figure 1 As shown, a system for preventing explosion during the preparation of methyl nitrite, including a mixer 1, a front flame arrester 2, a rear flame arrester 3, a safety valve 4, a bursting membrane 5, a liquid inlet 6, and a gas outlet 7 , gas cooler 8, nitrosation reaction raw material gas inlet 9, CO inlet 10, liquid extraction outlet 11, circulation pump 12, first valve 13, second valve 14, third valve 15 and decompression storage tank 16.

[0035] NO circulating gas a (temperature 60°C, pressure 5bar, volume flow 55000m 3 / h, the main components are nitrogen 60%, NO18%, methanol 12%, CO7%, etc.) enter the mixer 1 through the pre-flame arrester 2, and mix with the oxygen b entering the mixer 1 through the oxygen distributor, and the oxygen b ( Temperature 25℃, pressure 5bar, volume flow 1200m 3 / h) Enter the central main pipe of the oxygen distributor in the mixer 1 through the first valve 13, and then enter a total of 11 branch pipes connected to th...

Embodiment 2

[0041] A system for preventing explosion during the preparation of methyl nitrite, including mixer 1, pre-flame arrester 2, post-flame arrester 3, safety valve 4, bursting membrane 5, liquid inlet 6, gas outlet 7, and gas cooling device 8, nitrosation reaction raw material gas inlet 9, CO inlet 10, liquid extraction outlet 11, circulation pump 12, first valve 13, second valve 14, third valve 15 and decompression storage tank 16.

[0042] The liquid inlet 6 and the gas outlet 7 are arranged at the top of the nitrosation reaction tower, and the gas outlet 7 is connected to the gas cooler 8; The outlet 11 is connected back to the nitrosation reaction tower through a circulation pipeline, and a circulation pump 12 is arranged on the circulation pipeline.

[0043] The pre-flame arrester 2 adopts a gap-type deflagration-resistant flame arrester, and two layers of fire-retardant layers are connected in series. The maximum test safety gap (MESG) value of the fire-retardant layer near ...

Embodiment 3

[0049] A system for preventing explosion during the preparation of methyl nitrite, including mixer 1, pre-flame arrester 2, post-flame arrester 3, safety valve 4, bursting membrane 5, liquid inlet 6, gas outlet 7, and gas cooling device 8, nitrosation reaction raw material gas inlet 9, CO inlet 10, liquid extraction outlet 11, circulation pump 12, first valve 13, second valve 14, third valve 15 and decompression storage tank 16.

[0050] The liquid inlet 6 and the gas outlet 7 are arranged on the top of the nitrosation reaction tower, and the gas outlet 7 is connected to the gas cooler 8; The outlet 11 is connected back to the nitrosation reaction tower through a circulation pipeline, and a circulation pump 12 is arranged on the circulation pipeline.

[0051]The pre-flame arrester 2 adopts a gap-type deflagration-resistant flame arrester, and two layers of fire-retardant layers are connected in series. The maximum test safety gap (MESG) value of the fire-resistant layer near t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com