Hyperbranched polymer and preparation method and LED application thereof

A technology for hyperbranched polymers, polycondensation reactions, used in chemical instruments and methods, sustainable buildings, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

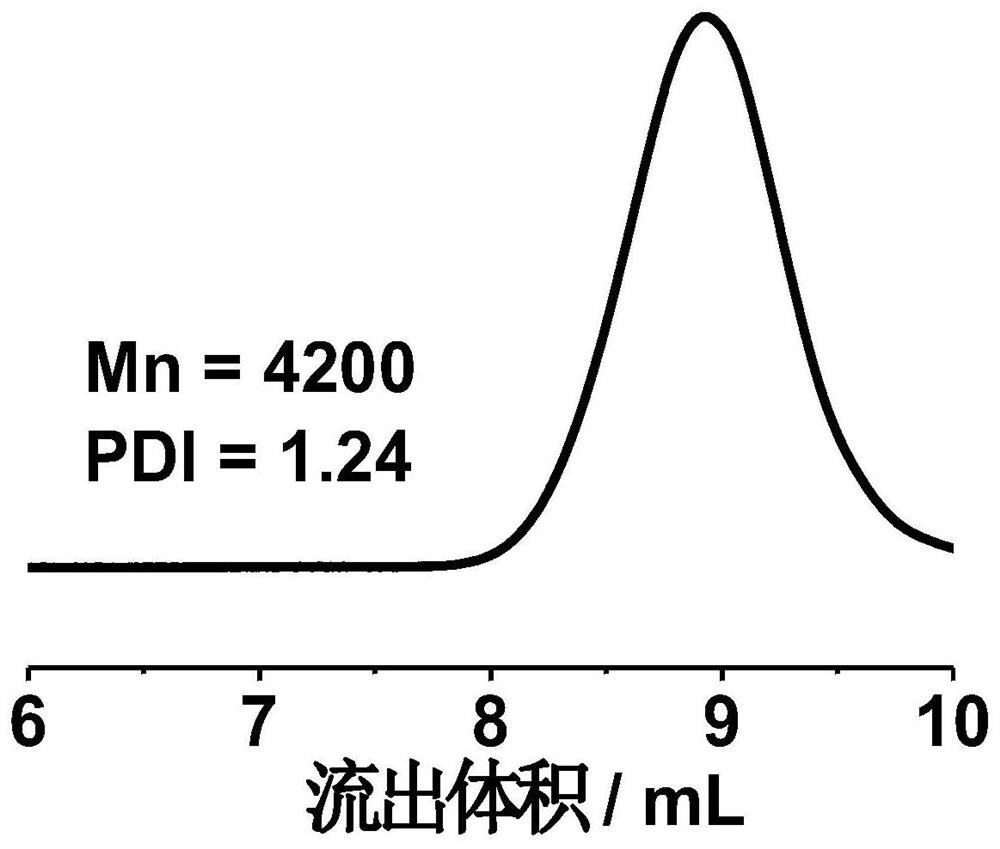

[0077] Embodiment 1: Preparation of hyperbranched polymer phosphor 1

[0078] This embodiment provides a method for preparing polymers through Barbier polycondensation reaction using 4,4'-dichlorobenzophenone as a reactive monomer, including the following steps:

[0079] Take a 100mL double-necked flask, coat the mouth with vacuum grease, plug it with a rubber stopper, and wrap it tightly with insulating tape to ensure good airtightness. Add magnesium chips (0.48g, 0.02mol) into the double-necked flask from the straight mouth, add magnets, and connect the condenser tube and straight air extraction joint in turn (all joints need to be coated with vacuum grease and clamped with plastic clips). Repeat the process of vacuuming, hot air gun blowing, cooling, and nitrogen flow three times. After passing the nitrogen gas for the last time, close the straight-shaped air extraction joint, connect a balloon filled with nitrogen gas, and then open the plug of the straight-shaped air ext...

Embodiment 2

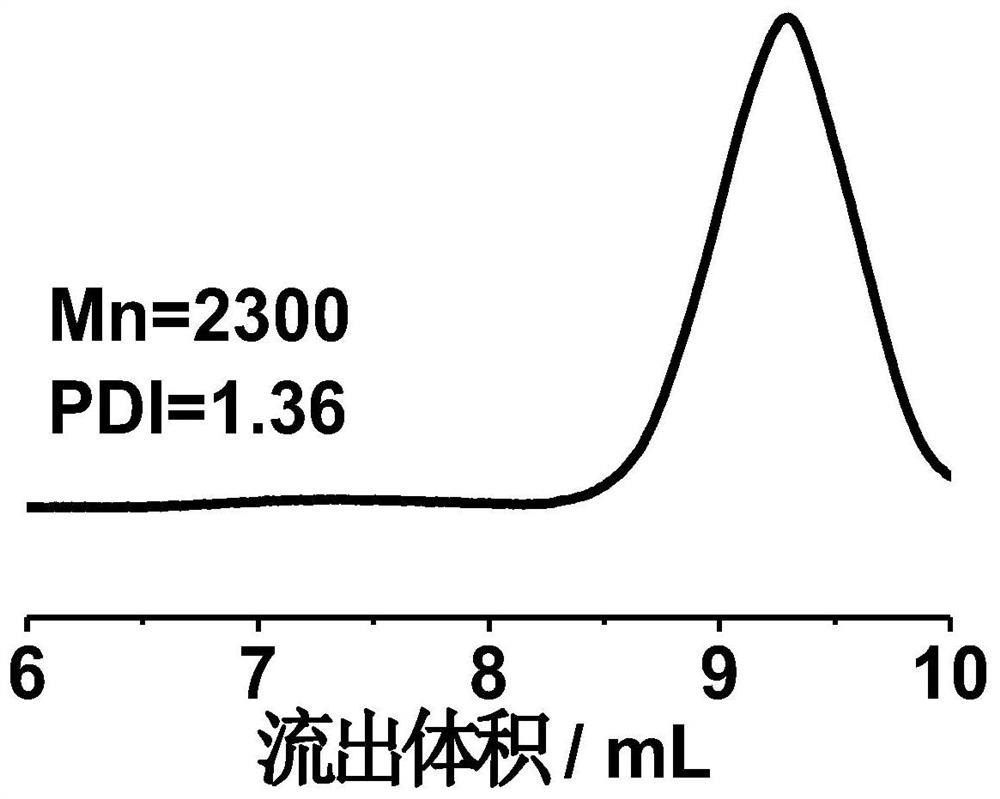

[0083] Embodiment 2: Preparation of hyperbranched polymer phosphor 2

[0084] This embodiment provides a method for preparing polymers through Barbier polycondensation reaction using 4,4'-dichlorobenzophenone as a reactive monomer, including the following steps:

[0085] Take a 100mL double-necked flask, coat the mouth with vacuum grease, plug it with a rubber stopper, and wrap it tightly with insulating tape to ensure good airtightness. Add magnesium chips (0.48g, 0.02mol) into the double-necked flask from the straight mouth, add magnets, and connect the condenser tube and straight air extraction joint in turn (all joints need to be coated with vacuum grease and clamped with plastic clips). Repeat the process of vacuuming, hot air gun blowing, cooling, and nitrogen flow three times. After passing the nitrogen gas for the last time, close the straight-shaped air extraction joint, connect a balloon filled with nitrogen gas, and then open the plug of the straight-shaped air ext...

Embodiment 3

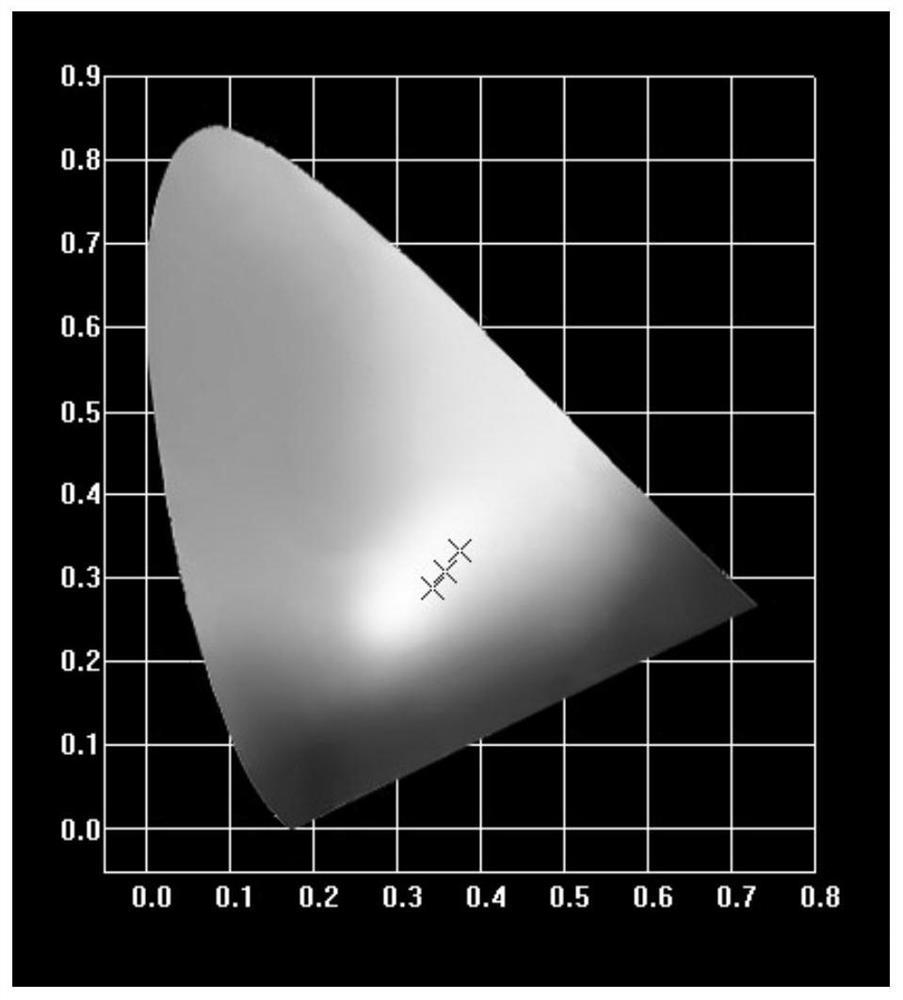

[0089] Example 3: Hyperbranched polymer phosphor powder 1 converts blue light wafer to prepare white light LED

[0090] Mix the hyperbranched polymer phosphor powder 1 prepared in Example 1 with the epoxy resin binder at a mass ratio of 3:1, 4:1, and 5:1, and apply it to a blue chip with an optimal emission wavelength of 460nm , to obtain white light LED 1 .

[0091] The performance test result of gained white light LED 1 sees image 3 , where CIE coordinates and color rendering index and color temperature include: (0.3413,0.2874)(80.2,4872), (0.3574,0.3073)(76.7,4181), (0.3751,0.3333)(77.4,3774).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com