Quantum dot ligand exchange method

A ligand exchange, quantum dot technology, applied in the field of quantum dots, can solve problems such as affecting the service life of the device and irreversible damage of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

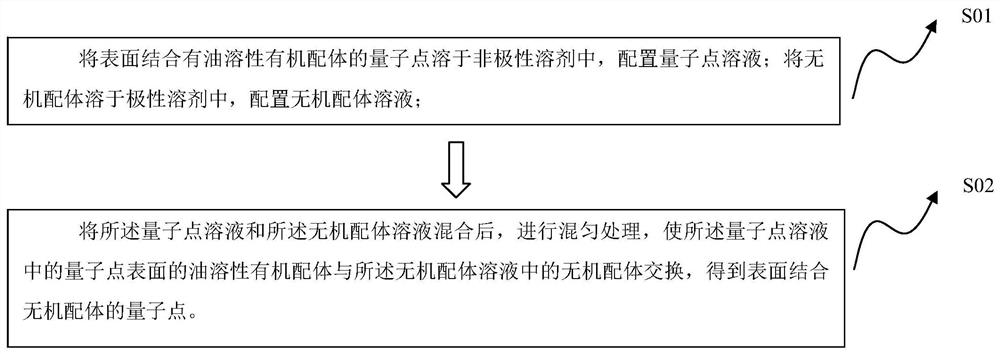

[0035] An inorganic ligand quantum dot is prepared according to the following steps:

[0036] Provide 5.0ml of surface-bound oil-soluble ODPA-modified cadmium selenide (4,4'-biphenyl ether dianhydride) quantum dot hexane solution with a concentration of 1mg / ml and 5.0ml of sodium sulfide formamide solution with a concentration of 1mg / ml , and mix the two to obtain a mixed solution.

[0037] The mixture was stirred at room temperature for 20 minutes, so that sodium sulfide was bound to the surface of the quantum dots, and transferred to the formamide solution in the lower layer. After collecting the formamide solution of the quantum dots in the lower layer, acetonitrile was added to remove the free ligands, and the quantum dots bound to the surface of sodium sulfide were collected.

Embodiment 2

[0039] An inorganic ligand quantum dot is prepared according to the following steps:

[0040] Provide 10.0 ml of ODPA-modified cadmium selenide quantum dot hexane solution with a concentration of 5 mg / ml and 10.0 ml of sodium selenide formamide solution with a concentration of 5 mg / ml, and mix them to obtain a mixed solution.

[0041] The mixture was stirred at room temperature for 50 minutes, so that the sodium selenide was bound to the surface of the quantum dots, and transferred to the formamide solution in the lower layer. After collecting the formamide solution of the quantum dots in the lower layer, acetonitrile was added to remove the free ligands, and the quantum dots bound to the surface of sodium selenide were collected.

Embodiment 3

[0043] An inorganic ligand quantum dot is prepared according to the following steps:

[0044] Provide 15.0ml concentration of 10mg / ml ODPA-modified cadmium selenide surface binding oil-soluble organic ligand quantum dot hexane solution and 10.0ml concentration of 1mg / ml sodium telluride formamide solution, mix the two, to obtain a mixture.

[0045] The mixture was stirred at room temperature for 20-50 minutes, so that the sodium telluride was combined on the surface of the quantum dots, and transferred to the formamide solution in the lower layer. After collecting the formamide solution of the quantum dots in the lower layer, acetonitrile was added to remove the free ligands, and the quantum dots bound to the surface of sodium telluride were collected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com