Hydration treatment method for reducing leakage current of formed foil

A technology of hydration treatment and foil hydration, applied in circuits, capacitors, electrical components, etc., can solve the problems of large leakage current, smaller holes, and blockage of the formed foil, and achieves the solution of hole blockage, increased density, and increased specific volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] According to an embodiment of the present invention, a method for preparing a chemically formed foil is provided, comprising: performing a hydration treatment on the corroded foil, and then performing a four-stage chemically formed,

[0030] The hydration treatment is: placing the corroded foil in an aqueous solution comprising component A, component B and component C, the component A containing SO 4 2- The substance, the component B is a weak acid, and the component C is a weak acid salt.

[0031] As a preferred embodiment of the present invention, the component A is sulfuric acid or / and sulfate, and the sulfate can include ammonium sulfate, aluminum sulfate, sodium sulfate, etc., but is not limited thereto.

[0032] According to the embodiment provided by the present invention, the component A is at least one of sulfuric acid, ammonium sulfate, aluminum sulfate, and sodium sulfate.

[0033] As a more preferred embodiment of the present invention, in the aqueous solu...

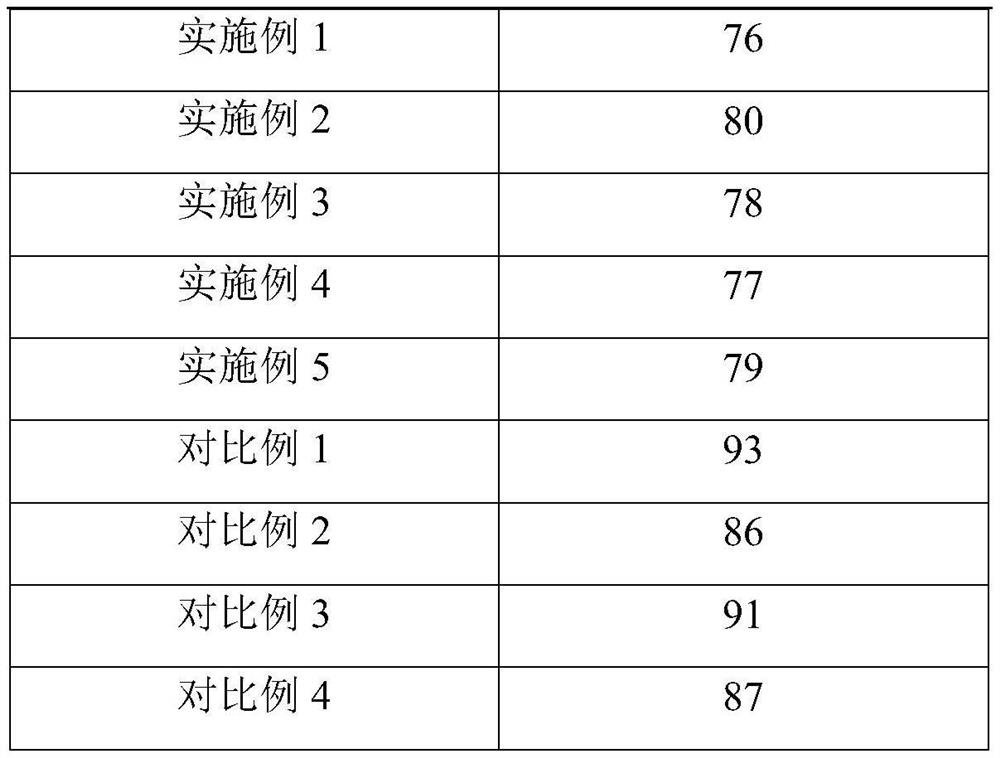

Embodiment 1

[0045] In this embodiment, the preparation method of chemically formed foil provided includes: performing hydration treatment on the corroded foil and then four-stage chemical formation; wherein the hydration treatment process is as follows:

[0046] The corroded foil was hydrated in an aqueous solution of sulfuric acid, oxalic acid and ammonium oxalate, wherein the concentration of sulfuric acid was 0.002mL / L, the concentration of oxalic acid was 0.05g / L, and the concentration of ammonium oxalate was 0.002mL / L. It is 5g / L; the processing condition is: boiling in water for 12min at 95°C.

Embodiment 2

[0048] In this embodiment, the preparation method of chemically formed foil provided includes: performing hydration treatment on the corroded foil and then four-stage chemical formation; wherein the hydration treatment process is as follows:

[0049] Hydrate the corroded foil in an aqueous solution of ammonium sulfate, oxalic acid, and ammonium oxalate, wherein the concentration of ammonium sulfate is 5 g / L, the concentration of oxalic acid is 0.05 g / L, and the concentration of ammonium oxalate is 0.05 g / L. The concentration is 5g / L; the treatment conditions are: boiling in water for 12 minutes at 95°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com