A method for fabricating upright AU nanocones with high adhesion to substrate surfaces

A substrate surface, high-adhesion technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, instruments, etc., can solve the problems that cannot be used to improve the adhesion between the upright gold nanocone and the substrate, and the low-temperature aging deformation of the gold nanocone Problems such as low temperature, low adhesion between gold nanocone and substrate, etc., to achieve the effect of easy operation, large range and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

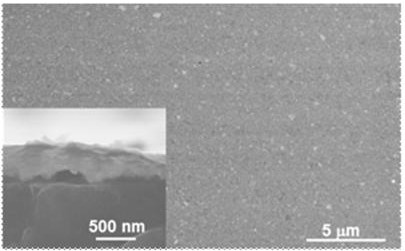

[0022] a. Clean the silicon wafer: Soak the silicon wafer (size 1*1) crystal direction (111) in analytical pure acetone for 3 minutes at room temperature, put the silicon wafer soaked in acetone into an ultrasonic container filled with deionized water , cleaning for 10 min; use CP4A lotion to scratch the surface of the ultrasonically treated silicon wafer until the surface roughness is less than 1 nm; put the scratched silicon wafer into 7% hydrofluoric acid aqueous solution for wet method etching, soaking for 10 min, immersing the silicon wafer after hydrofluoric acid aqueous solution wet etching treatment in an ultrasonic container filled with deionized water, cleaning for 5 min, to obtain a silicon wafer with a clean surface, and using nitrogen gas to clean the silicon wafer Blow dry and store in a desiccator; if figure 1 Shown, 5μm top view and 500nm section view.

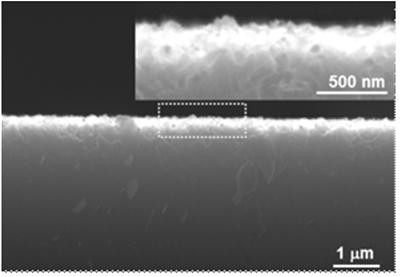

[0023] b. Silicon wafer etching: Dip the silicon wafer directly into the etchant for 3 minutes at room temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com