Treatment method of MDI production tail gas

A treatment method and tail gas technology are applied in the field of MDI production tail gas treatment, which can solve the problems of difficult waste liquid treatment, no comprehensive recovery and utilization method of chlorobenzene, condensation of light components, etc., so as to solve waste waste and environmental pollution. , Extend stable operation time, maximize the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

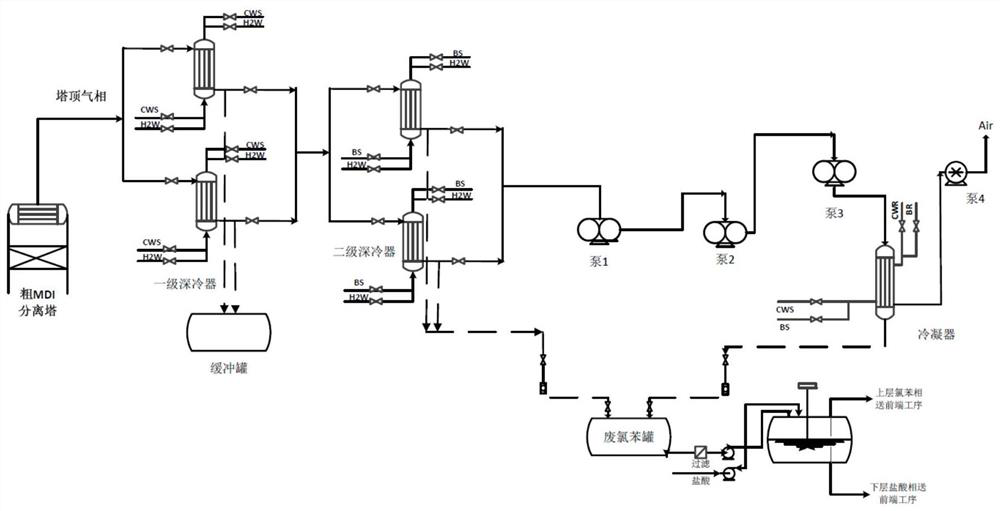

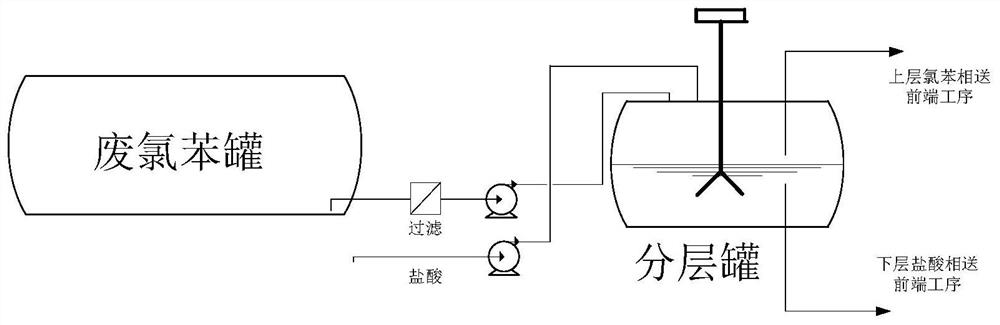

[0048] A method for treating tail gas of an isocyanate vacuum system, the specific steps are:

[0049] (1) Carry out compositional analysis to a tower top vacuum tail gas in the thick MDI separation process, the result is as shown in table 1:

[0050] Table 1. Analysis of tail gas composition before cryogenic treatment

[0051] Exhaust components content / % chlorobenzene 44.3 MDI 2.5 P.I. 5.1 HCl 0.1 Air 48

[0052] (2) According to the method provided by the present invention, the exhaust gas first passes through the first-stage cryogenic heat exchanger before entering the unit, and the temperature is set at 10°C. After the pressure drop of the cryocooler is too high, switch the spare cryocooler, and switch the warm water chemical material to the replaced cryocooler at the same time, and analyze the material after the chemical material by gas chromatography. The material composition is shown in Table 2:

[0053] Table 2. Composit...

Embodiment 2

[0075] A method for treating tail gas of an isocyanate vacuum system, the specific steps are:

[0076] (1) Carry out compositional analysis to a tower top vacuum tail gas in the thick MDI separation process, the result is as shown in table 8:

[0077] Table 8. Analysis of tail gas composition before cryogenic treatment

[0078] Exhaust components content / % chlorobenzene 36.4 MDI 2.3 P.I. 6.2 HCl 0.1 Air 55

[0079] (2) According to the method provided by the present invention, the exhaust gas first passes through the first-stage cryogenic heat exchanger before entering the unit, and the temperature is set at 15°C. After the pressure drop of the cryocooler is too high, switch the spare cryocooler, and switch the warm water chemical material to the replaced cryocooler at the same time, and analyze the material after the chemical material by gas chromatography. The material composition is as shown in Table 9:

[0080] Table 9. Compo...

Embodiment 3

[0100] A method for treating tail gas of an isocyanate vacuum system, the specific steps are:

[0101] (1) Carry out compositional analysis to a tower top vacuum tail gas in the thick MDI separation process, the result is as shown in table 15:

[0102] Table 15. Analysis of tail gas composition before cryogenic treatment

[0103] Exhaust components content / % chlorobenzene 45.9 MDI 3.2 P.I. 5.8 HCl 0.1 Air 45

[0104] (2) According to the method provided by the present invention, the exhaust gas first passes through the first-stage cryogenic heat exchanger before entering the unit, and the temperature is set at 5°C. After the pressure drop of the cryocooler is too high, switch the spare cryocooler, and switch the warm water chemical material to the replaced cryocooler at the same time, and analyze the material after the chemical material by gas chromatography. The material composition is shown in Table 16:

[0105] Table 16. Compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com