VOCs waste gas recovery treatment equipment and treatment process

A technology for waste gas recovery and treatment equipment, which is applied in gas treatment, vapor condensation, combined devices, etc., can solve the problems of short waste gas residence time, environmental pollution, and condenser tube damage, so as to improve condensation and liquefaction efficiency, increase residence time, increase The effect of high contact probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings.

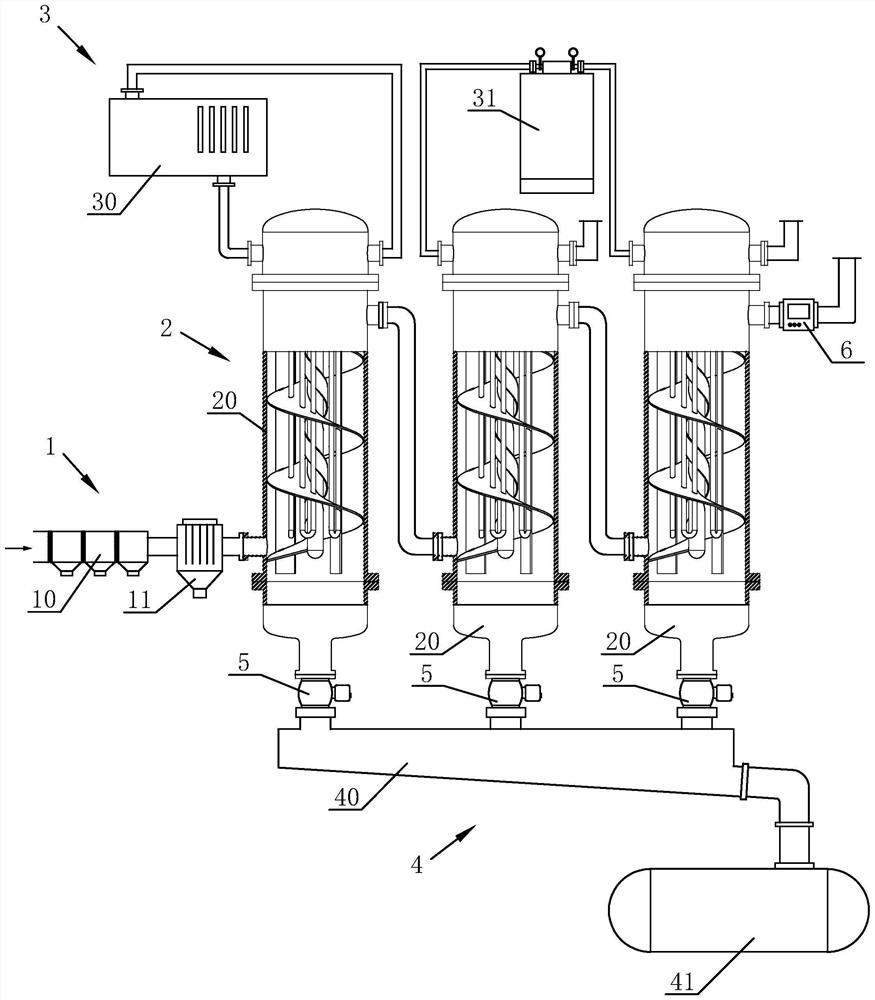

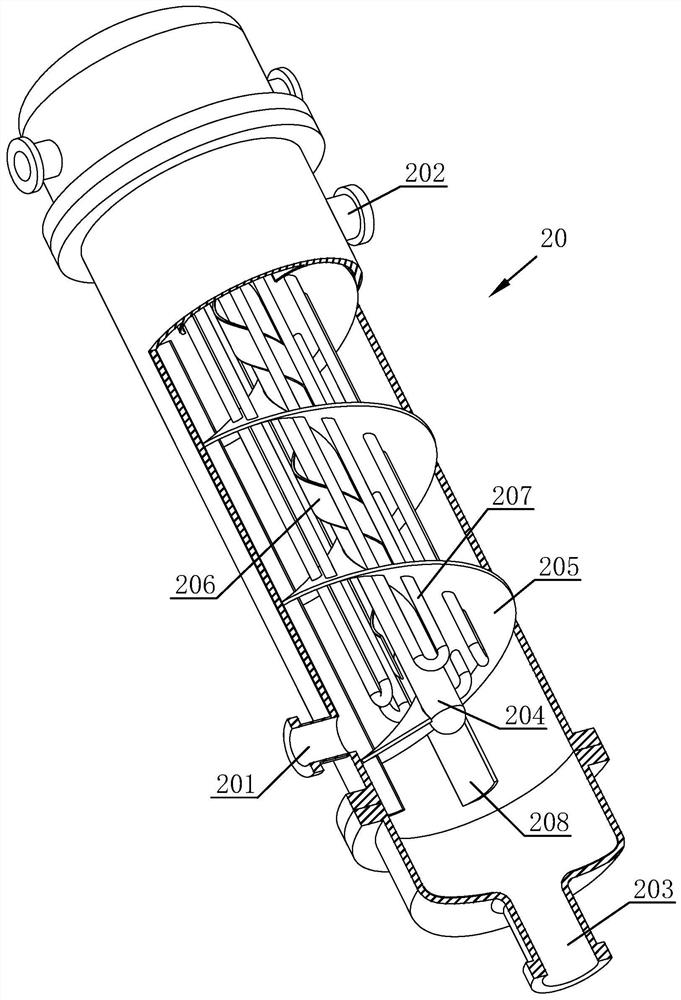

[0045] Such as figure 1 The shown VOCs waste gas recovery and treatment equipment includes a pretreatment device 1, a condensation tank group 2, a refrigerant liquid supply device 3 and a recovery device 4. The condensation tank group 2 includes three condensation tanks 20 arranged side by side, and the three condensation tanks 20 pass through The pipes communicate with each other; the refrigerant liquid supply device 3 includes a chiller 30 for providing circulating cold water to the first condensation tank 20 and two liquid nitrogen tanks for providing liquid nitrogen in the second and third condensation tanks 20 31.

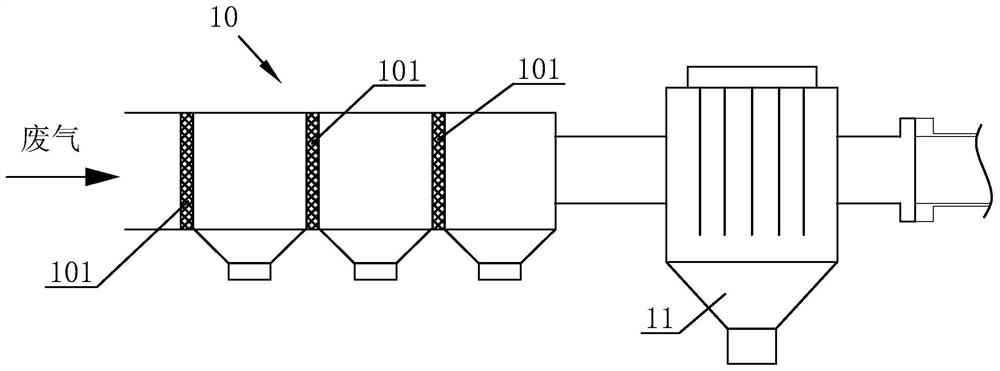

[0046] Such as figure 2As shown, the pre-processing device 1 includes a filter mechanism 10 and an electrostatic precipitator 11. The filter mechanism 10 includes three filter screens 101 with different mesh numbers. The filter screens 101 are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com