Preparation method and application of transition metal double hydroxide nano-film and carbon nanotube composite material

A double hydroxide and transition metal technology, applied in the field of electrocatalysis, can solve the problems of incapable mass production and difficulty in obtaining few-layer LDHs, and achieve the effects of convenient operation, guaranteed shape control, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Weigh 3.49g of cobalt nitrate and 0.63g of vanadium chloride and dissolve them in 50mL of deionized water saturated with oxygen, stir and dissolve in an oxygen protective atmosphere, and the flow rate of oxygen gas is 70mL / min to form a transparent solution.

[0039] (2) Add 0.1 g of carbon nanotubes into the above transparent solution, and continue to stir for 30 minutes under the condition of aeration of oxygen to obtain a uniform suspension.

[0040] (3) 25 mL of sodium hydroxide with a concentration of 2 mol / L was quickly added to the above suspension, the oxygen flow rate was increased to 80 mL / min, the stirring speed was 500 r / min, and the time was 30 min to obtain a brown precipitate.

[0041] (4) The above-mentioned brown precipitate was successively washed three times with deionized water and absolute ethanol, and dried in a vacuum oven at 30° C. for 15 hours to obtain a composite material of nano-film cobalt vanadium double hydroxide and carbon nanotubes.

...

Embodiment 2

[0047] (1) Weigh 3.49g of cobalt nitrate and 0.74g of manganese acetate and dissolve them in 50mL of deionized water saturated with oxygen, stir and dissolve in an oxygen protective atmosphere, and the flow rate of oxygen gas is 70mL / min to form a transparent solution.

[0048] (2) Add 0.08 g of carbon nanotubes into the above solution, and continue stirring for 30 minutes under the condition of aeration of oxygen.

[0049] (3) Quickly add 20 mL of sodium hydroxide with a concentration of 2 mol / L to the above mixed suspension, increase the oxygen flow rate to 80 mL / min, stir at 500 r / min for 1.5 h, and obtain a dark brown precipitate.

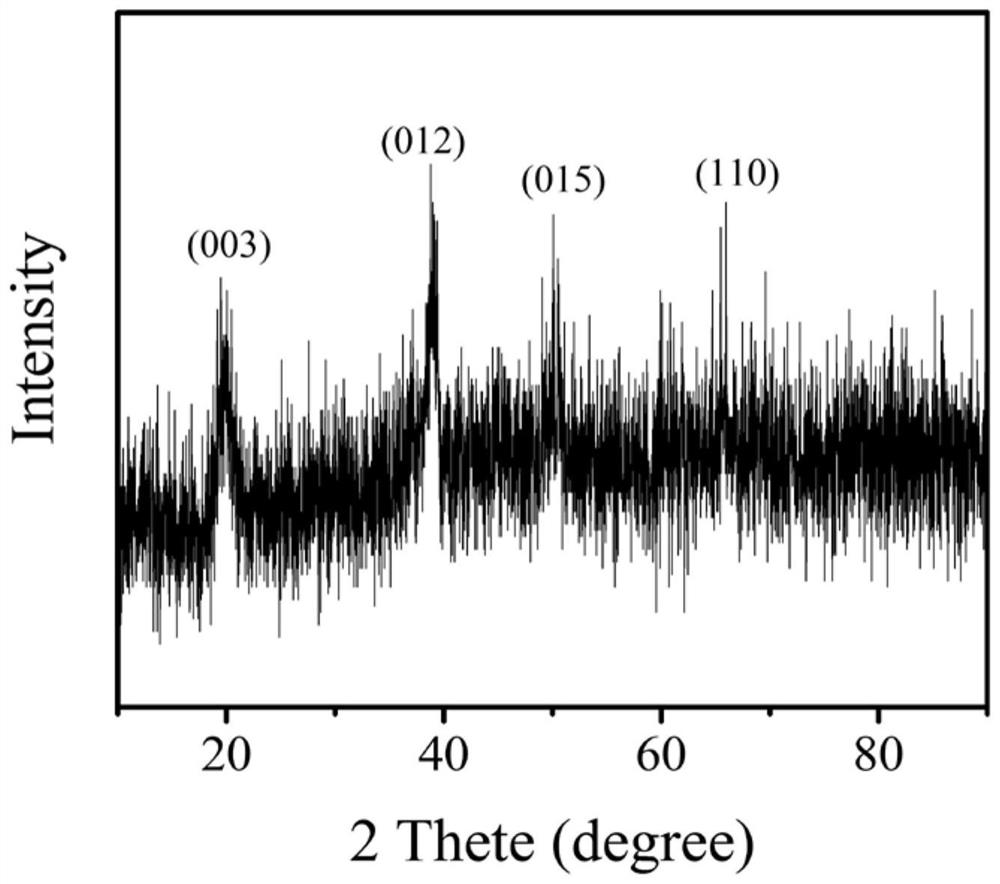

[0050] (4) The above-mentioned brown precipitate was washed three times by deionized water and absolute ethanol respectively, and dried in a vacuum oven at 30° C. for 15 hours to obtain a composite material of nano-film cobalt-manganese double hydroxide and carbon nanotubes. Looks like figure 2 and 7 shown.

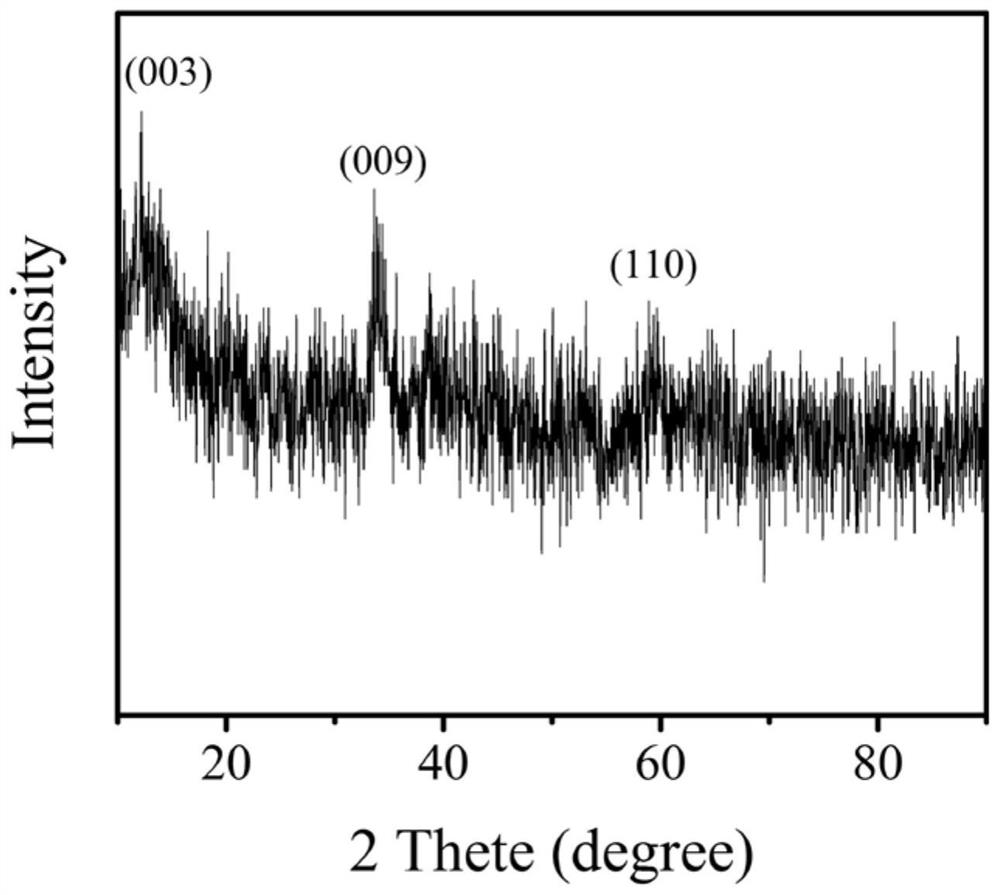

[0051] figure 2 For the X-ray...

Embodiment 3

[0055] (1) Weigh 3.49g of cobalt nitrate and 0.87g of nickel nitrate and dissolve in 50mL of deionized water saturated with oxygen, stir and dissolve in an oxygen protective atmosphere, and the flow rate of oxygen gas is 70mL / min to form a transparent solution.

[0056] (2) Add 0.2 g of carbon nanotubes into the above solution, and continue stirring for 60 minutes under the condition of aeration of oxygen.

[0057] (3) Quickly add 20 mL of sodium hydroxide with a concentration of 2 mol / L to the above mixed suspension, increase the oxygen flow rate to 100 mL / min, stir at 600 r / min, and 0.5 h to obtain a dark green precipitate.

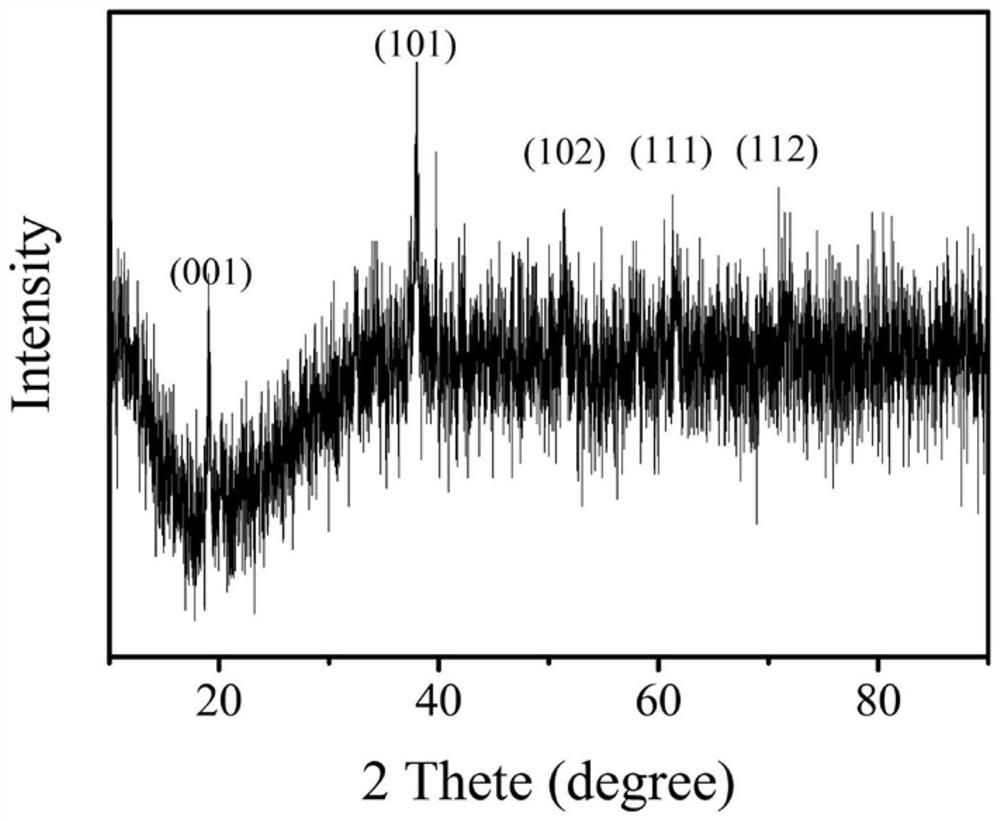

[0058] (4) The above-mentioned dark green precipitate was washed three times with deionized water and absolute ethanol successively, and dried in a vacuum oven at 35°C for 20h to obtain a composite material of nano-film cobalt-nickel double hydroxide and carbon nanotubes. looks like image 3 and 8 shown.

[0059] image 3 For the X-ray diffraction s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com