A kind of nano-flaky copper sulfide material, preparation method and application

A nano-flaky, copper sulfide technology, applied in the field of nanomaterials, can solve the problems of preparation reaction conditions, product structure and morphology, large size differences, difficult mass production, etc., and achieves smooth surface, high production efficiency, and good application prospects. Effect

Active Publication Date: 2022-06-03

GUIZHOU INST OF TECH

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In order to solve the problem that the existing copper sulfide nanomaterial preparation method is limited by the harsh preparation reaction conditions, there are large differences in the shape and size of the product structure, and it is difficult to mass-produce the problem

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Login to View More

Abstract

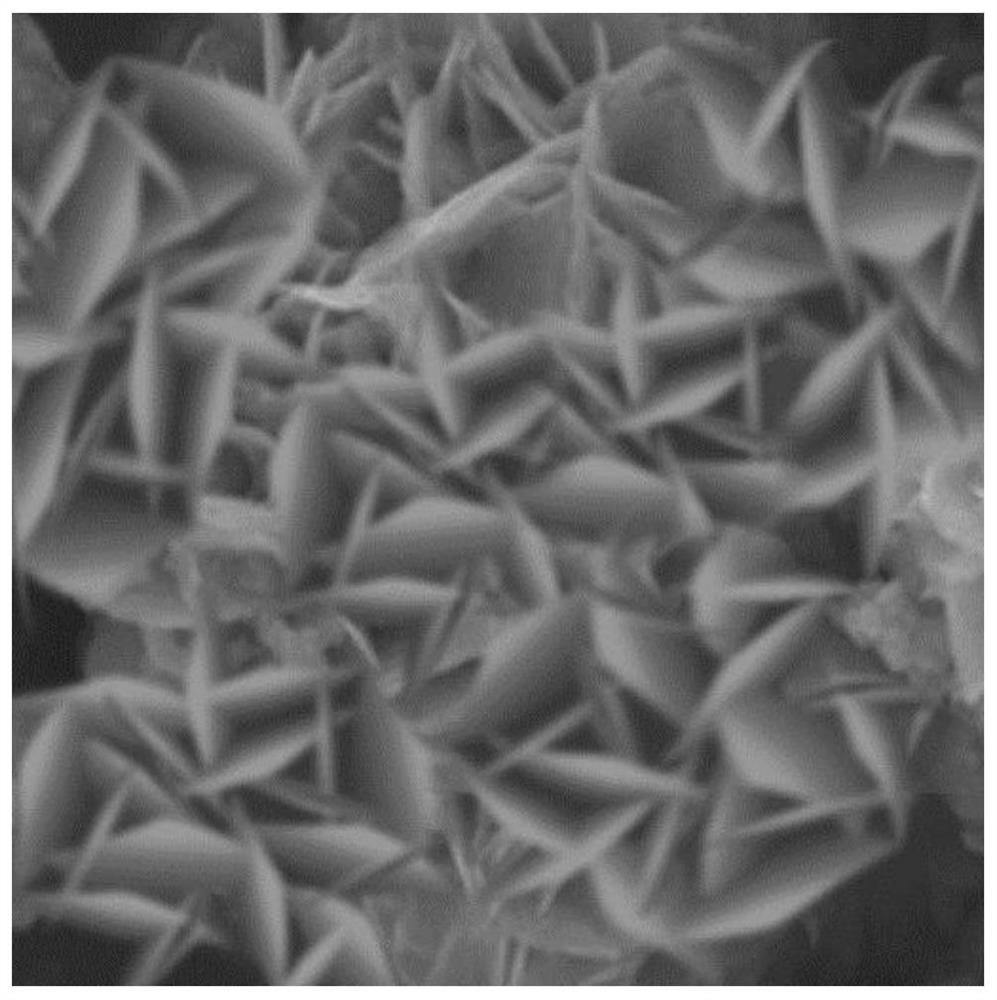

The invention discloses a nano-flaky copper sulfide material, a preparation method and an application thereof. The key points of the technical scheme are: continuously inject moist sulfur dioxide and carbon monoxide into a water-bath reaction kettle containing an aqueous solution of sodium hydroxide, and electrolyze it under a high-temperature vacuum environment. Reduction reaction to obtain a mixed solution of sodium sulfide, hydrogen sulfide and sulfur element; after cooling the water bath reactor to normal temperature, stir the aqueous solution in the water bath reactor, and discharge the gas in the water bath reactor to obtain a mixed solution of sodium sulfide and sulfur element solution; add copper powder and copper salt into a water bath reactor, react in a high-temperature environment, and obtain nano-copper sulfide coarse material after centrifugation, washing, and drying; the nano-copper sulfide coarse material is passed through multiple groups of side-by-side in the grinding device After the steel ball is subjected to disorderly grinding, a prismatic sheet-shaped nano-copper sulfide material is obtained. Its shape is prismatic sheet-like copper sulfide, the thickness of the middle part is greater than that of the edge, the surface is smooth, the structure is stable, the difference between individuals is small, and it can be mass-produced.

Description

A kind of nano-flaky copper sulfide material, preparation method and application technical field The present invention relates to the technical field of nanomaterials, more specifically, it relates to a kind of nano-flaky copper sulfide material, system Preparation methods and applications. Background technique [0002] Nanomaterials are also referred to as ultrafine particle materials, generally referring to particles with a size between 1-100 nm. it has a surface effect response, small size effect and macroscopic quantum tunneling effect. Nano-copper sulfide, as a kind of nano-functional material, is an important Transition metal-chalcogenide semiconductor materials exhibiting a unique layered structure, in photocatalysis, electrocatalysis, water It has shown excellent performance in the fields of energy storage, energy storage, and biomedicine. At present, there are many methods for preparing copper sulfide nanomaterials. Such as grinding, chemical precipitatio...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

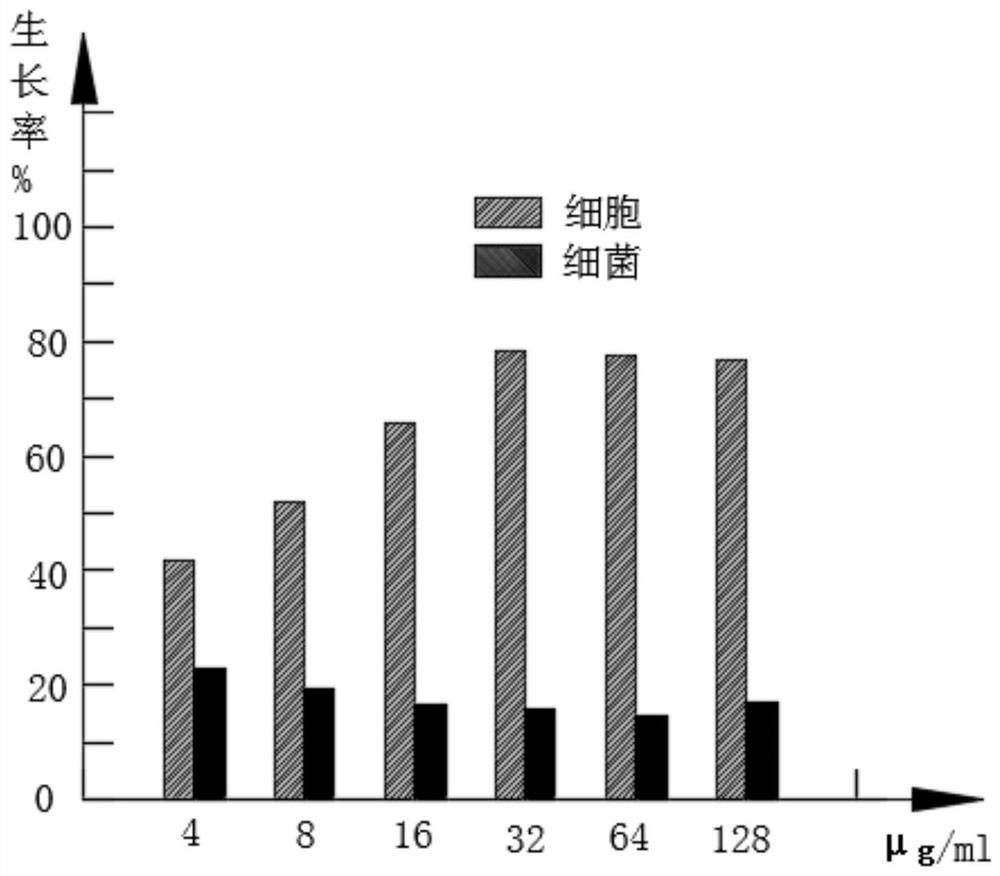

IPC IPC(8): C01G3/12B82Y40/00C25B1/01C25B1/14C25B1/22A61K33/34A61P31/04

CPCC01G3/12B82Y40/00C25B1/00C25B1/14C25B1/22A61K33/34A61P31/04C01P2004/24C01P2004/22C01P2004/64C01P2004/62Y02E60/36

Inventor 舒群威

Owner GUIZHOU INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com