Clay target

The technology of flying saucer and target blank is applied in the field of environmental protection flying saucer target, which can solve the problems of unfavorable growth of lawn vegetation in shooting range, increase product cost, not environmental protection, etc., and achieve the effects of tight adhesion, low product cost and favorable growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

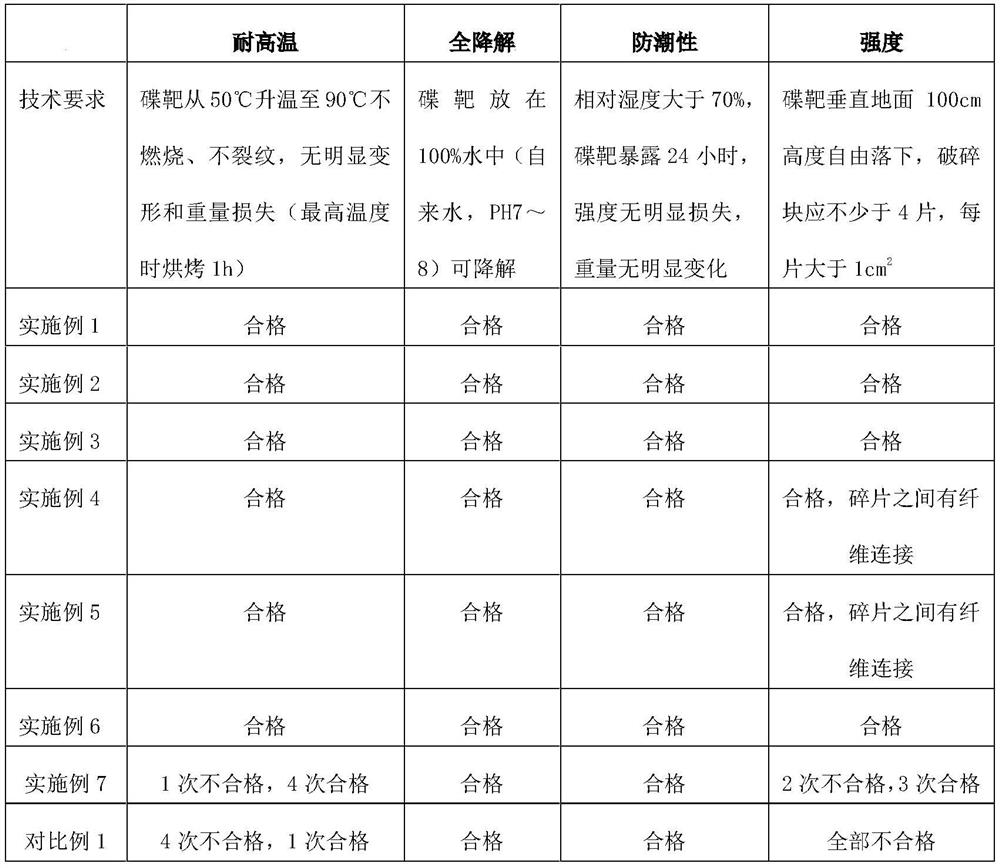

Examples

preparation example Construction

[0047] In a specific embodiment, the preparation method of the flying saucer target comprises:

[0048] a. Mix clay and stone powder, and stir at 1000-1500 rpm for more than 30 minutes to obtain mixture 1;

[0049] b. In step a, add pregelatinized starch, sodium carboxymethyl starch, micropowder silica gel, talcum powder, magnesium stearate and water in a wet amount and mix, and stir at 1000-1500 rpm for more than 20 minutes to obtain mixture 2 ;

[0050] c. molding the mixture 2 to obtain a flying saucer target blank;

[0051] d. Obtained by drying the flying saucer target blank at 50-80°C for 30-80 minutes.

[0052] In a specific embodiment, step a is stirred at 1000-1200 rpm for 30-60 min.

[0053] In a specific embodiment, the molding in step c is vacuum extrusion molding.

[0054] The second technical problem to be solved by the present invention is to provide a method for preparing a flying saucer target.

[0055] For solving second technical problem of the present ...

Embodiment 1

[0068] a. Mix 600 g of 100-200 mesh clay and 200 g of 400-600 mesh stone powder, and stir at 1500 rpm for 40 minutes to obtain mixture 1;

[0069] b. Add 100g of pregelatinized starch, 5g of sodium carboxymethyl starch, 3g of 800-1000 mesh micropowder silica gel, 10g of 1500-1800 mesh talc powder, 4g of magnesium stearate and a wetting amount of water in step a. Stir at 1200 rpm for 20 minutes to obtain mixture 2;

[0070] c. Extruding the mixture 2 to obtain the flying saucer target blank;

[0071] d. Dry the flying saucer target blank at 50-60° C. for 40 minutes to obtain the flying saucer target.

Embodiment 2

[0073] a. Mix 630 g of 100-200 mesh clay and 180 g of 400-600 mesh stone powder, and stir at 1500 rpm for 40 minutes to obtain mixture 1;

[0074] b. Add 90g of pregelatinized starch, 5g of sodium carboxymethyl starch, 3g of 800-1000 mesh micropowder silica gel, 10g of 1500-1800 mesh talc powder, 4g of magnesium stearate and a wetting amount of water in step a. Stir at 1200 rpm for 20 minutes to obtain mixture 2;

[0075] c. Extruding the mixture 2 to obtain the flying saucer target blank;

[0076] d. Dry the flying saucer target blank at 50-60° C. for 40 minutes to obtain the flying saucer target.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com