Heat-resistant hydrolysis-resistant glass fiber-reinforced PBT/EVOH composition and preparation method thereof

A composition and hydrolysis-resistant technology, applied in the field of polymer materials, can solve the problems of increased comprehensive cost of materials, attenuation of heat and oxygen aging resistance, poor compatibility, etc., to delay hydrolysis and thermal degradation rates, and maintain high performance , Improve the effect of long-term heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

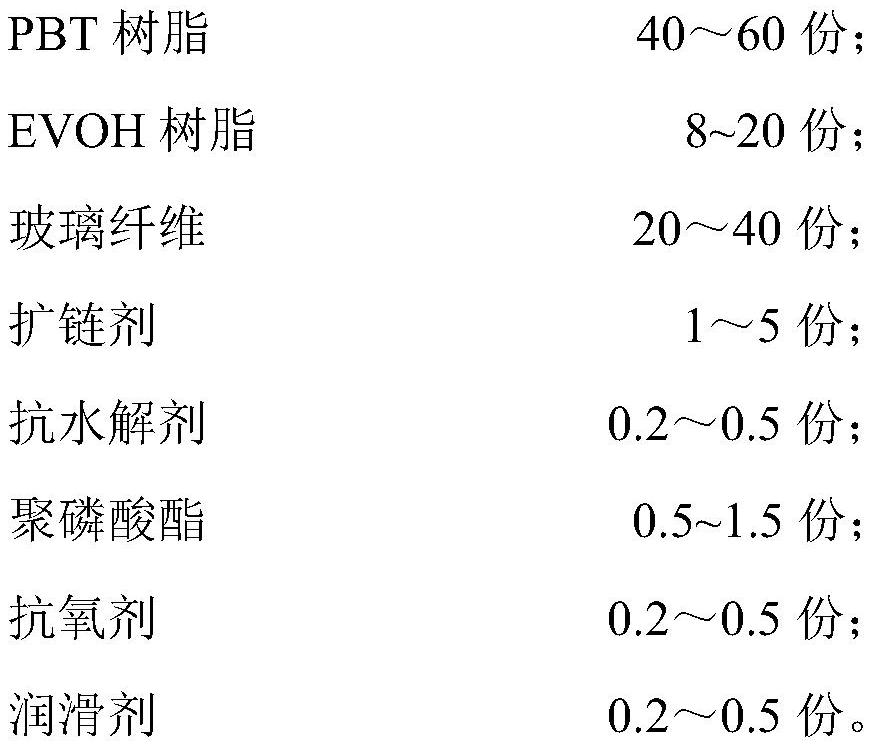

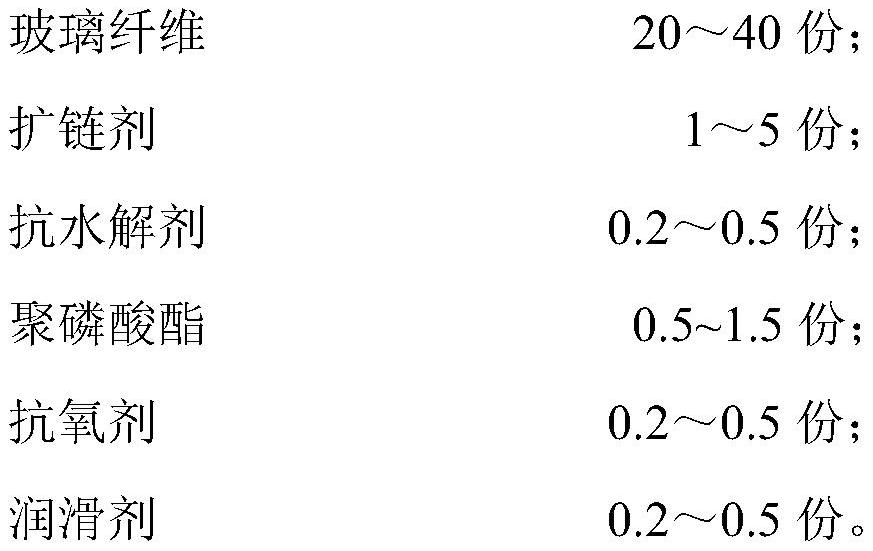

Method used

Image

Examples

Embodiment 1

[0043] The results of Example 1 are compared with the results of Comparative Examples 1-3 and show: when EVOH and polyphosphate were not added, the hydrolysis resistance and thermal aging resistance of PBT were all poor; when EVOH or polyphosphate components were added alone, The hydrolysis resistance and heat aging resistance of the PBT composition are not as good as the PBT / EVOH composition when the two types of components are added at the same time, which proves that EVOH and polyphosphate have a synergistic effect, and the joint effect can significantly improve the PBT composition. Hydrolysis resistance and heat aging resistance.

[0044] The results of Examples 1-5 show that: when adding 1% polyphosphate, the introduction of 8-20% EVOH resin has little effect on the initial physical properties of glass fiber reinforced PBT materials, and significantly improves the long-term and short-term properties of the material. Hydrolysis resistance and long-term thermal oxygen aging...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com