Glucose control process for increasing yield of L-isoleucine

A technology of isoleucine and glucose, applied in the field of glucose control technology, can solve problems such as difficulty in product purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

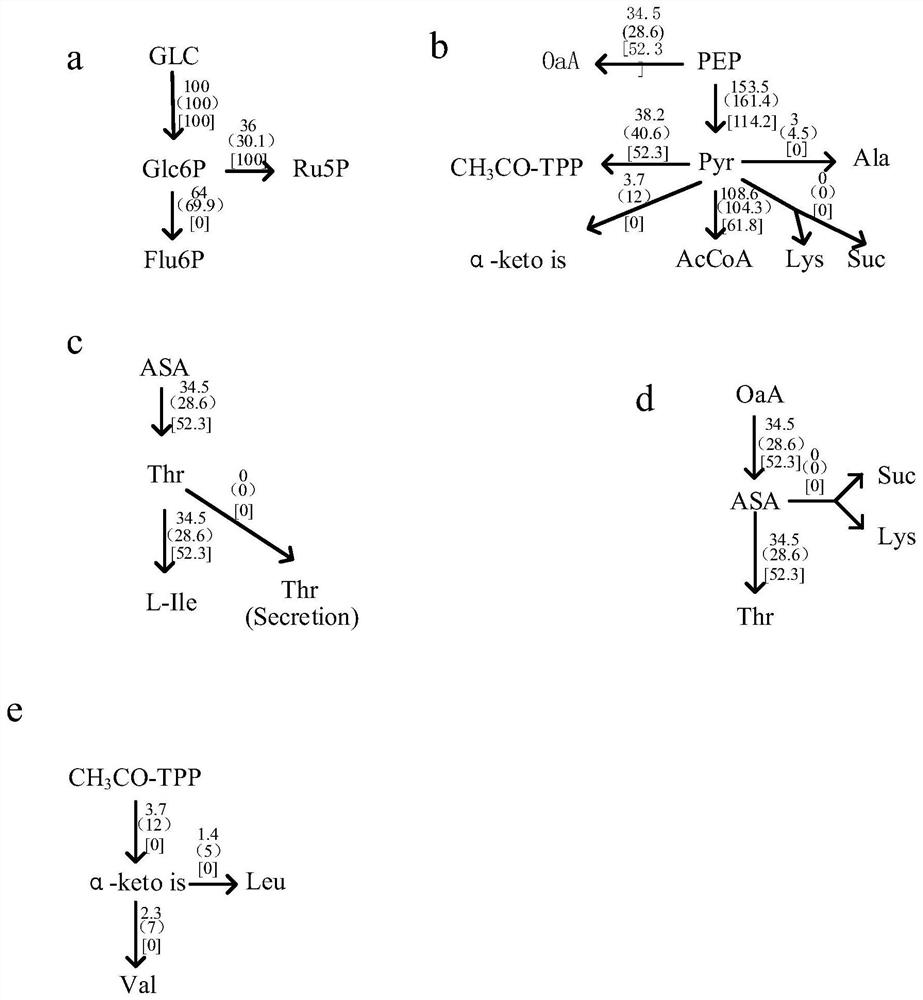

Method used

Image

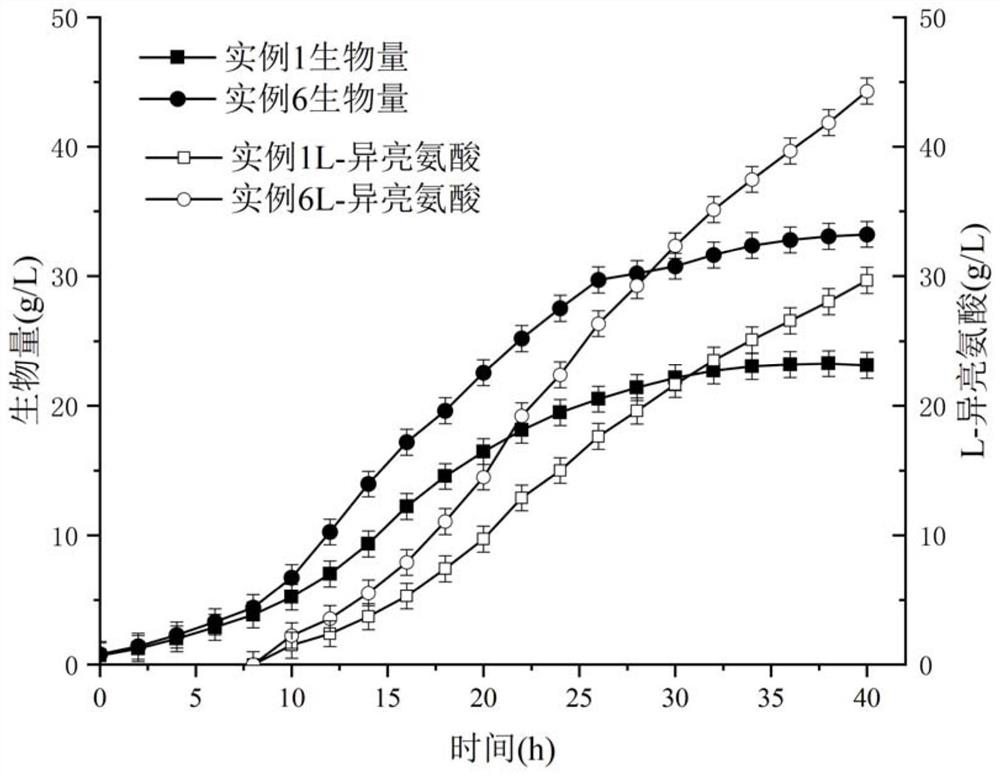

Examples

Embodiment 1

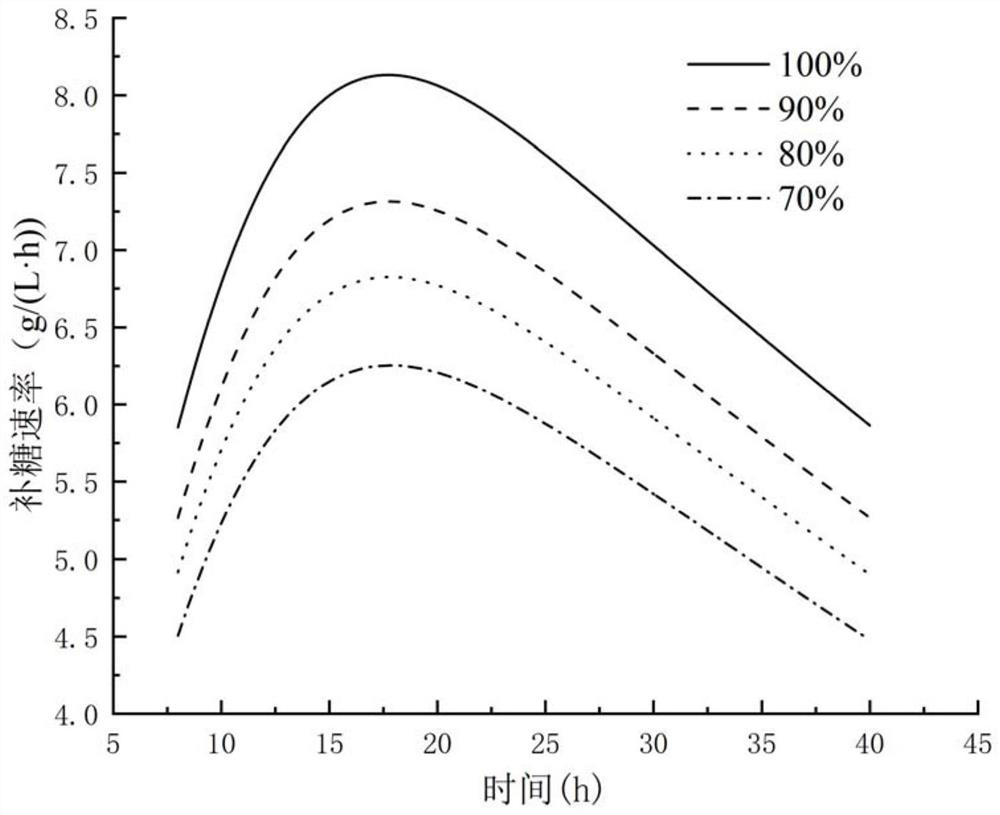

[0026] A glucose control process for increasing the output of L-isoleucine, the specific steps are as follows:

[0027] (1) Activation culture: take out the bacteria preservation tube (Corynebacterium glutamate YILM1504, provided by Metabolic Engineering Laboratory of Tianjin University of Science and Technology) from the -80°C refrigerator, pass two generations on the slope, and perform activation culture to obtain the activated strain .

[0028] The slant medium used includes: peptone 5g / L, beef extract 10g / L, yeast powder 5g / L, corn steep liquor dry powder 20g / L, KH 2 PO 4 1 g / L, MgSO 4 0.2 g / L, NaCl1 g / L, agar powder 25g / L, lysine 0.2g / L, pH=6.8~7.0;

[0029] (2) Seed cultivation: all the activated strains were inoculated into seed tanks to obtain seed liquid.

[0030] The seed medium used includes: glucose 35g / L, MgSO 4 0.6 g / L, KH 2 PO 4 1.5 g / L, (NH4 ) 2 SO 4 1g / L, yeast extract powder 5g / L, corn steep liquor dry powder 35g / L, V B1 0.3mg / L, foam enemy 0.2g / L, ...

Embodiment 2

[0036] A glucose control process for increasing the yield of L-isoleucine, referring to Example 1, the difference is that: the initial base material glucose concentration is 60g / L, and the glucose is added at the maximum sugar supplement rate.

Embodiment 3

[0038] A glucose control process for increasing the yield of L-isoleucine, referring to Example 1, the difference is that the initial bottom material glucose concentration is 90g / L, and the glucose is added at the maximum sugar supplement rate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com