Aluminum deoxidation method for nitrogen-containing super stainless steel

A stainless steel and aluminum deoxidation technology, applied in the field of iron and steel metallurgy, can solve the problems of difficult deoxidation process, accelerated furnace lining erosion, shortened furnace lining life and other problems, and achieves the effect of easy industrialized production, reduced erosion, and improved cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

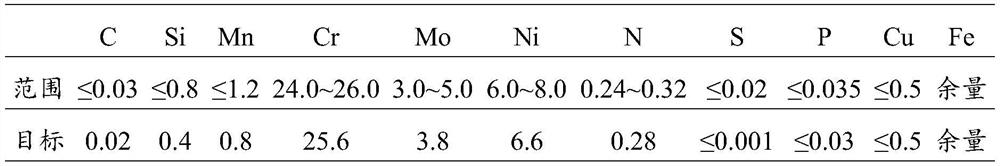

[0044] The "EAF smelting + AOD smelting + LF refining + continuous casting" process is used to smelt S32750 super duplex stainless steel with a molten steel volume of 30t. The target steel composition (wt.%) is shown in Table 1:

[0045] Table 1 Target steel composition (wt.%)

[0046]

[0047] Aluminum deoxidation method is as follows:

[0048] (1) Carry out EAF smelting and AOD smelting on nitrogen-containing super stainless steel in sequence, and the smelting process is carried out according to conventional methods; in the process of AOD smelting, decarburization, ferrosilicon reduction of chromium, and nitrogen control by blowing argon and nitrogen mixed gas are carried out;

[0049] (2) After the chromium is reduced, the slag is removed, and the exposed area of the molten steel exceeds 90% after the slag is removed. Add 15kg / t lime (CaO content>95wt.%), 6kg / t fluorite (CaF 2 content>wt.85%) and 2kg / t aluminum block for desulfurization;

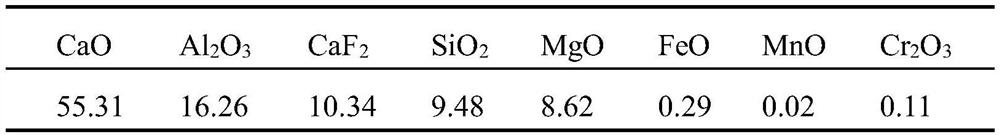

[0050] (3) After desulfur...

Embodiment 2

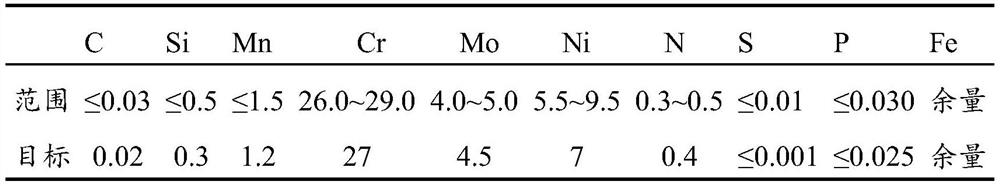

[0061] The "EAF smelting + AOD smelting + LF refining + die casting" process is used to smelt S32707 super duplex stainless steel with a molten steel volume of 30t. The target steel composition (wt.%) is shown in Table 3:

[0062] Table 3 Target steel composition (wt.%)

[0063]

[0064] Aluminum deoxidation method is as follows:

[0065] (1) Carry out EAF smelting and AOD smelting on nitrogen-containing super stainless steel in sequence, and the smelting process is carried out according to conventional methods; in the process of AOD smelting, decarburization, ferrosilicon reduction of chromium, and nitrogen control by blowing argon and nitrogen mixed gas are carried out;

[0066] (2) After the chromium is reduced, the slag is removed, and the exposed area of the molten steel exceeds 90% after the slag is removed. Add 17kg / t lime (CaO content>95wt.%), 7kg / t fluorite (CaF 2 content>wt.85%) and 2.5kg / t aluminum block for desulfurization;

[0067] (3) After desulfurizati...

Embodiment 3

[0078] 254SMO super austenitic stainless steel is smelted by the "EAF+VOD+LF+die casting" process, and the amount of molten steel is 30t. Target steel composition (wt.%) is shown in Table 5:

[0079] Table 5 Target steel composition (wt.%)

[0080]

[0081] Aluminum deoxidation method is as follows:

[0082] (1) Carry out EAF smelting and VOD smelting to nitrogen-containing super stainless steel in sequence, and the smelting process is carried out according to conventional methods; in the process of VOD smelting, decarburization and ferrosilicon reduction of chromium are carried out;

[0083] (2) After the chromium is reduced, the slag is removed, and the exposed area of the molten steel exceeds 90% after the slag is removed. Add 20kg / t lime (CaO content>95wt.%), 8kg / t fluorite (CaF 2 content>wt.85%) and 3kg / t aluminum block for desulfurization;

[0084] (3) After desulfurization for 14 minutes, carry out vacuum degassing, and then blow nitrogen to control nitrogen. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com