Connection process of internal binding wire of power module

A technology of power modules and bonding wires, which is applied to semiconductor/solid-state device components, semiconductor devices, electrical components, etc., can solve the problems of reduced power cycle life, complex process, and increased power module loss, etc., to achieve improved power cycle life , increase the contact area, reduce the effect of on-resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

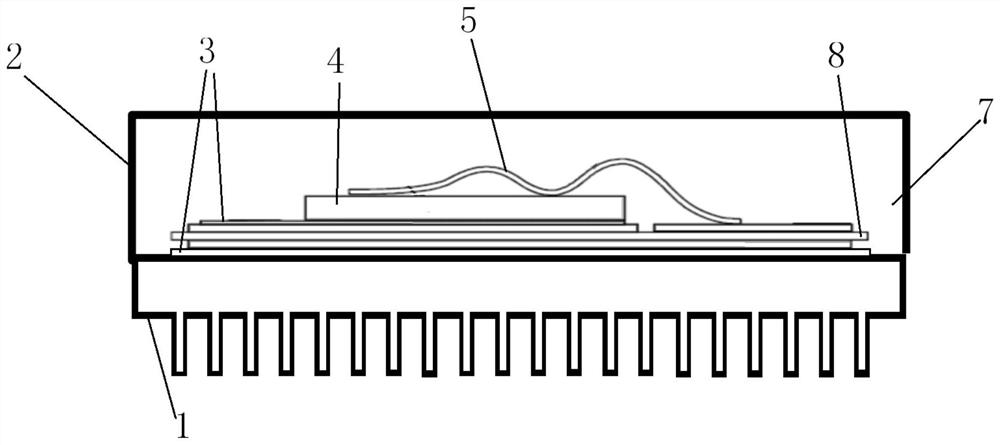

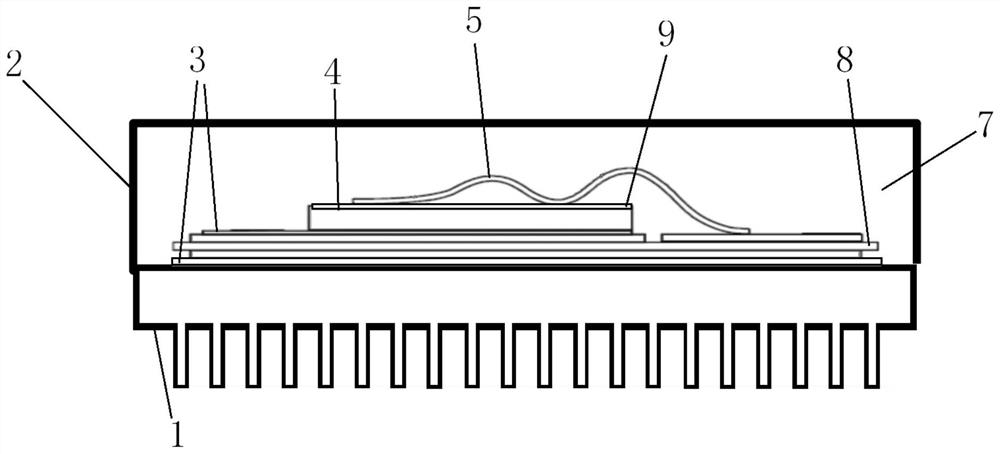

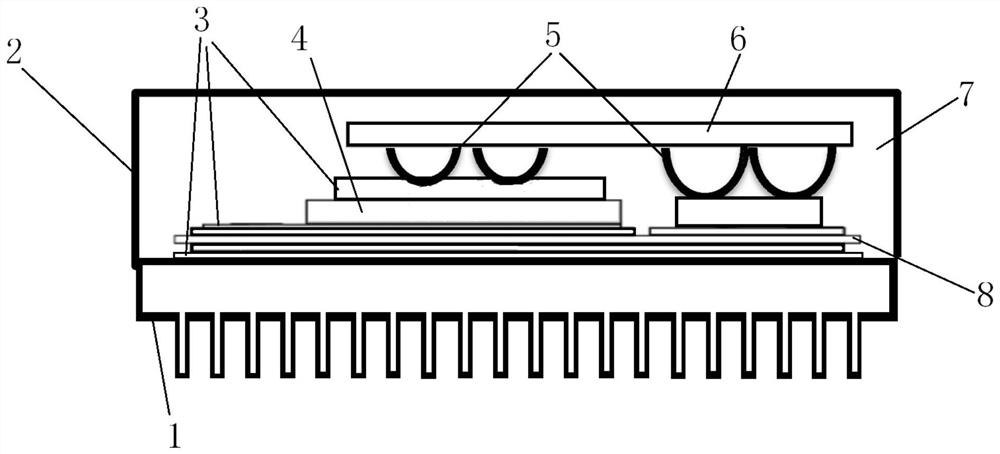

[0023] as attached image 3 As shown, an embodiment of the present invention provides a connection process for bonding wires inside a power module, and the connection process includes the following steps:

[0024] Connect the copper bonding wire with a diameter of 300um to a 1.0mm thick copper plate by ultrasonic bonding, and then connect the copper bonding wire to the semiconductor chip 4 and the power module that have been connected to the insulating heat dissipation material by welding on the electrodes. The shape of the copper bonding wire is arc.

Embodiment 2

[0026] as attached image 3 As shown, an embodiment of the present invention provides a connection process for bonding wires inside a power module, and the connection process includes the following steps:

[0027] Connect the copper bonding wire with a diameter of 500um to a 2mm thick copper plate by ultrasonic bonding, and then connect the copper bonding wire to the semiconductor chip 4 that has been connected to the insulating heat dissipation material and the power module by welding on the electrode. The shape of the copper bonding wire is arc.

Embodiment 3

[0029] as attached image 3 As shown, an embodiment of the present invention provides a connection process for bonding wires inside a power module, and the connection process includes the following steps:

[0030] Connect the copper bonding wire with a diameter of 200um to a 500um thick copper plate by ultrasonic bonding, and then connect the copper bonding wire to the semiconductor chip 4 that has been connected to the insulating heat dissipation material and the power module by welding on the electrode. The shape of the copper bonding wire is arc.

[0031] Specifically, the power modules described in Embodiments 1 to 3 also include a metal base plate 1, a housing 2, a solder layer 3, insulation and heat dissipation materials, silica gel 7, and a double-sided copper-clad ceramic substrate 8 (DBC). The metal bottom plate 1 and the double-sided copper-clad ceramic substrate 8 are connected by welding. The solder layer 3 is soldered with solder paste or tin sheet. The metal bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com