Preparation method of Ni/C composite conductive powder

A technology of composite conductive powder and graphite powder, which is applied in the direction of metal/alloy conductor, cable/conductor manufacturing, carbon-silicon compound conductor, etc., can solve the application limitation of Ni/C composite powder, the coating of nickel shell is not dense, Solve the problems of high cost of nickel plating, and achieve the effect of uniform, dense and continuous coating, strong bonding force and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

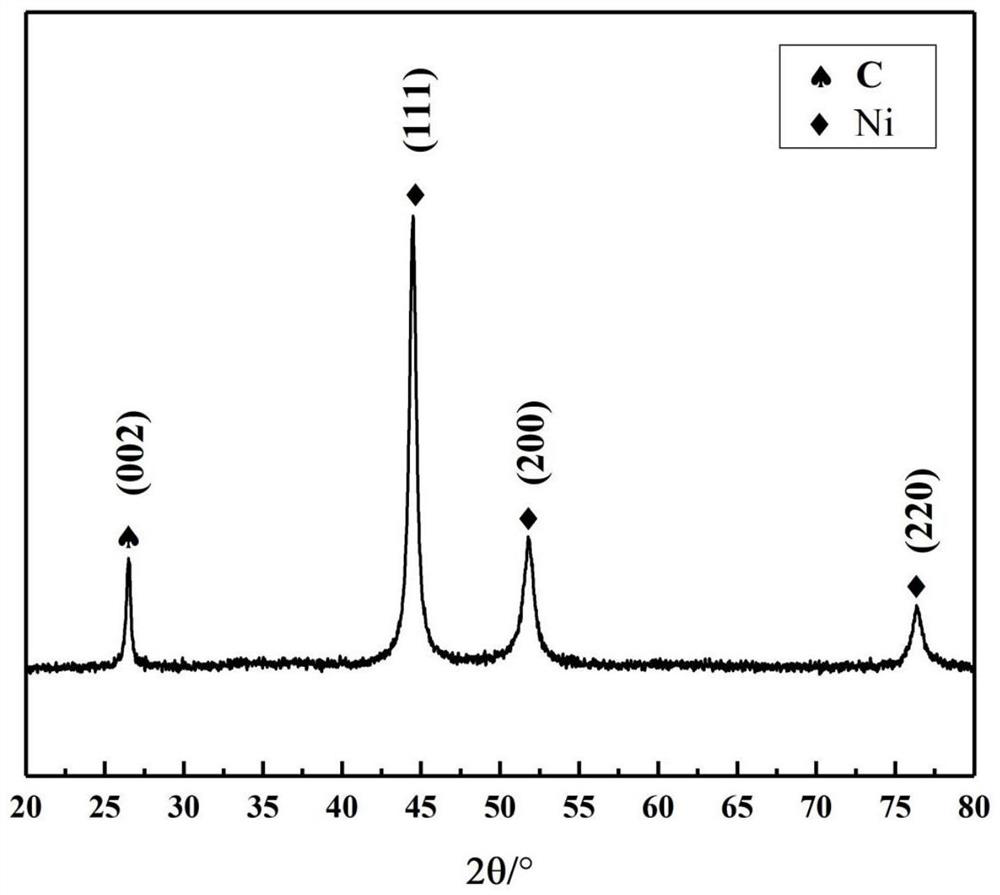

[0029] A kind of preparation method of Ni / C composite conductive powder of the present invention, specifically implement according to the following steps:

[0030] Step 1, placing graphite in a muffle furnace for calcination, and keeping it warm for a period of time to obtain flaky graphite;

[0031] The heating temperature of the muffle furnace is 350-400°C, and the holding time is 1h-3h;

[0032] Step 2, utilizing lye to carry out degreasing treatment to the flake graphite;

[0033] Specifically: put the flake graphite in the lye, perform ultrasonic treatment, then suction filter and wash with deionized water until the filtrate is neutral;

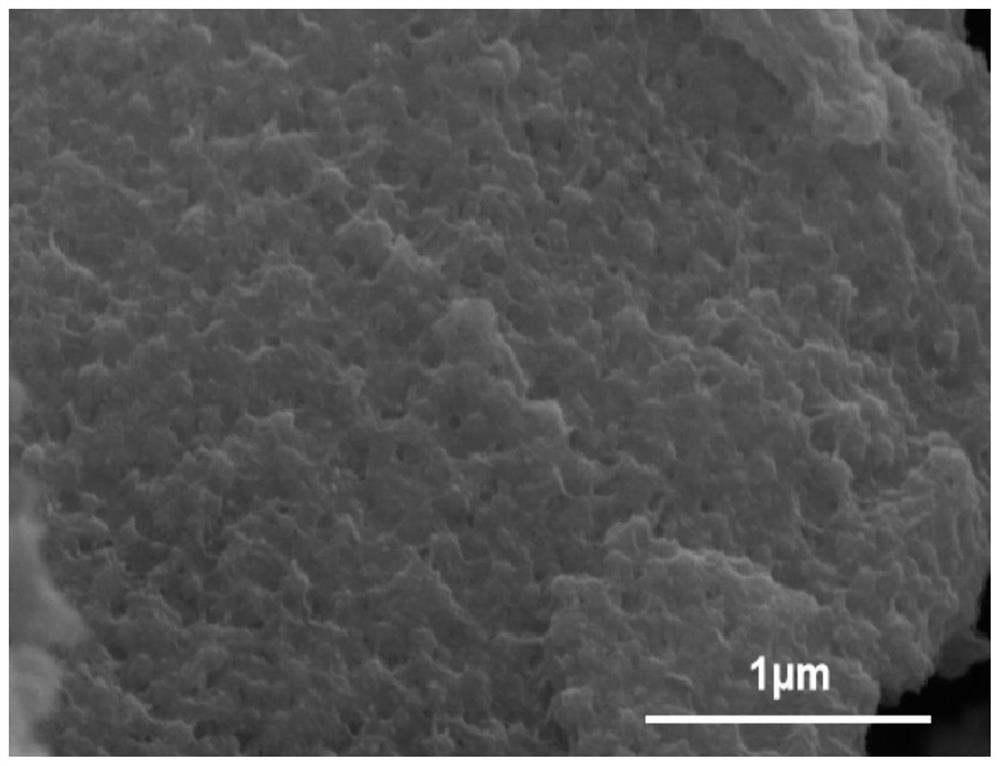

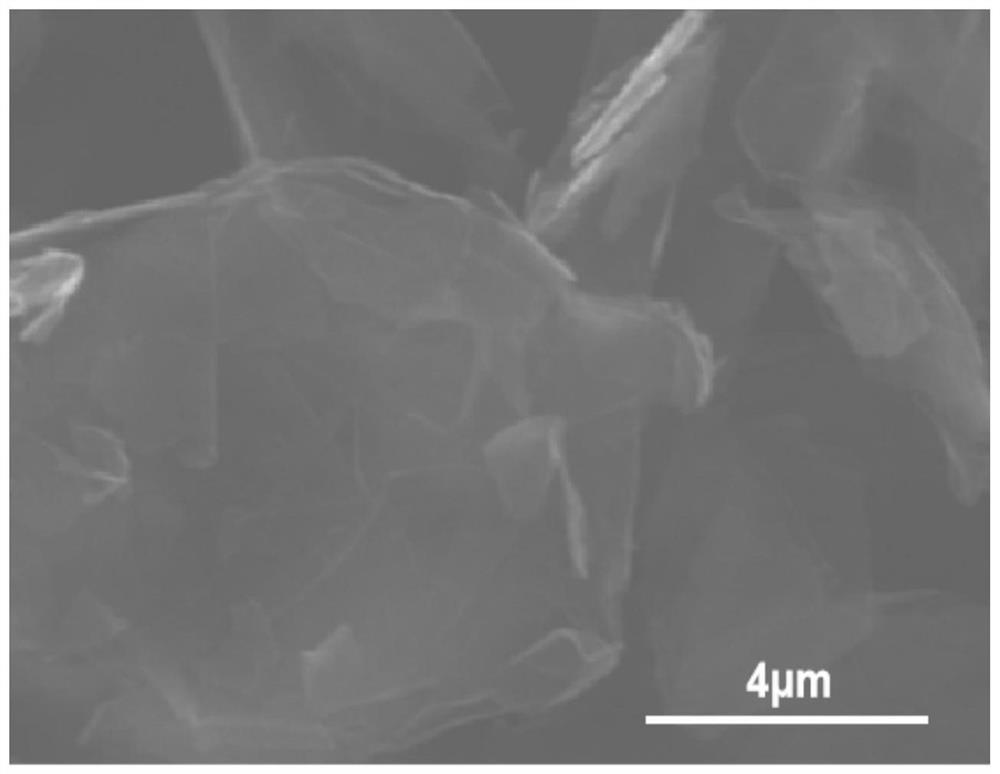

[0034] The average particle size of flaky graphite is 4 μm to 15 μm, and the purity is greater than 98%;

[0035] The mass ratio of flake graphite to deionized water is 1:70~180; the mass concentration of lye is 80~160g / L; the ultrasonic treatment time is 35~65min, and the temperature is 60~85℃.

[0036] Step 3, placing the graphite p...

Embodiment 1

[0048] A kind of preparation method of Ni / C composite conductive powder, specifically implement according to the following steps:

[0049] Step 1, place the graphite in a muffle furnace, calcinate it at 350°C and keep it warm for 2.5 hours;

[0050] Step 2, the flaky graphite is placed in the lye for ultrasonic treatment, then suction filtered and washed with deionized water until the filtrate is neutral, the mass ratio of the flaky graphite to deionized water is 1:70, and the temperature of the ultrasonic wave is 65°C, the treatment time is 35min, and the mass concentration of the lye used is 80g / L;

[0051] Step 3, place the graphite powder obtained in step 2 in dilute hydrochloric acid solution for ultrasonic treatment, then suction filter and wash with deionized water until the filtrate is neutral, the mass ratio of graphite powder to dilute hydrochloric acid solution is 1:90, The mass concentration of dilute hydrochloric acid is 6ml / L, the time of ultrasonic treatment is...

Embodiment 2

[0059] A kind of preparation method of Ni / C composite conductive powder, specifically implement according to the following steps:

[0060] Step 1, place the graphite in a muffle furnace for calcination at 360°C and keep it warm for 2 hours;

[0061] Step 2, the flaky graphite is placed in the lye for ultrasonic treatment, then suction filtered and washed with deionized water until the filtrate is neutral, the mass ratio of the flaky graphite to deionized water is 1:120, and the temperature of the ultrasonic wave is 70°C, the treatment time is 45min, and the mass concentration of the lye used is 100g / L;

[0062] Step 3, place the graphite powder obtained in step 2 in dilute hydrochloric acid solution for ultrasonic treatment, then suction filter and wash with deionized water until the filtrate is neutral, the mass ratio of graphite to dilute hydrochloric acid solution is 1:100, dilute hydrochloric acid The mass concentration is 7ml / L, the ultrasonic treatment time is 35min, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com