An integrated device and method for removing sulfate, nitrite and organic matter in wastewater

A nitrite and sulfate technology, which is applied in biological treatment devices, chemical instruments and methods, water pollutants, etc., can solve the problems of poor process stability, large floor space, and high treatment costs, so as to improve productivity and occupy more space. The effect of small ground area and large transmission flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The following non-limiting examples can enable those skilled in the art to understand the present invention more fully, but do not limit the present invention in any way.

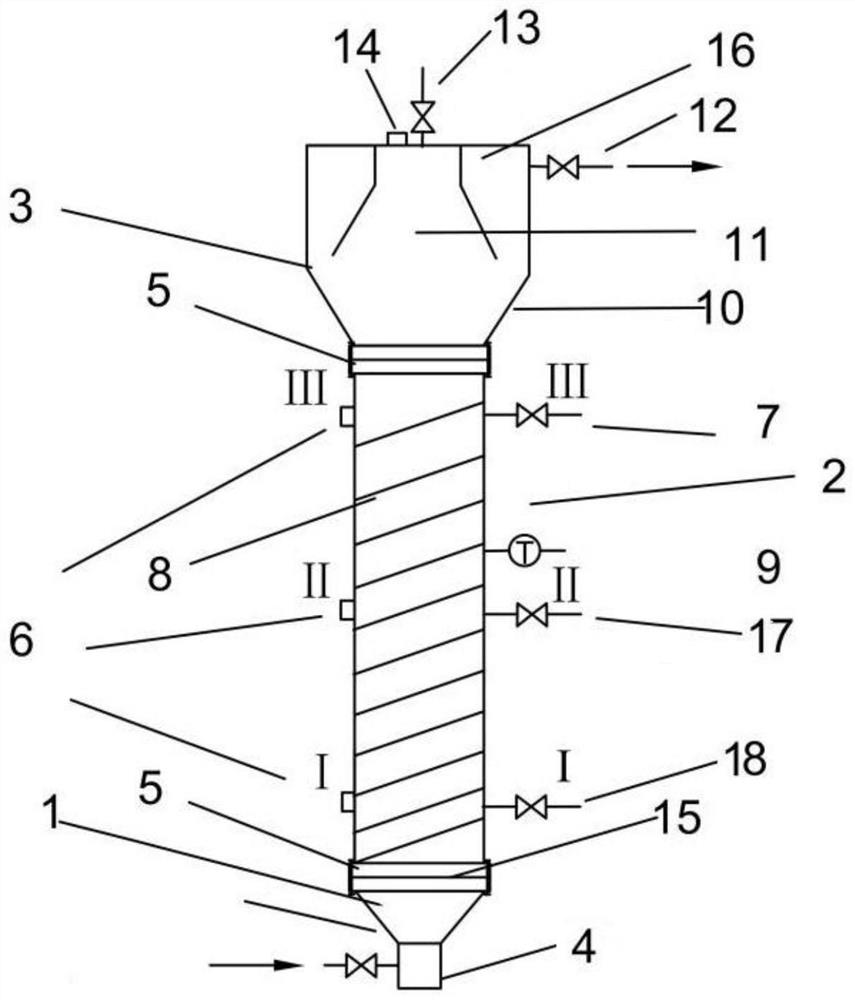

[0050] Such as figure 1 As shown, an integrated removal device for sulfate, nitrite and organic matter is an upflow suspended sludge anaerobic reactor, from bottom to top there are water inlet 1, reactor 2 and three-phase separation 3, the water inlet and the reactor and between the reactor and the three-phase separator are connected by a flange structure 5; Sludge supplement port Ⅰ7, sludge supplement port Ⅱ17, sludge supplement port Ⅲ18, all three sludge supplement ports are equipped with valves, with an inner diameter of 1.0cm;

[0051] The three-phase separator includes a gas collecting hood 11, an exhaust valve 13, a sludge settling unit 10, a water outlet 12, and an inspection port 14; the gas collecting hood and the sludge settling unit are set up and down opposite to each other; The upper p...

Embodiment 2

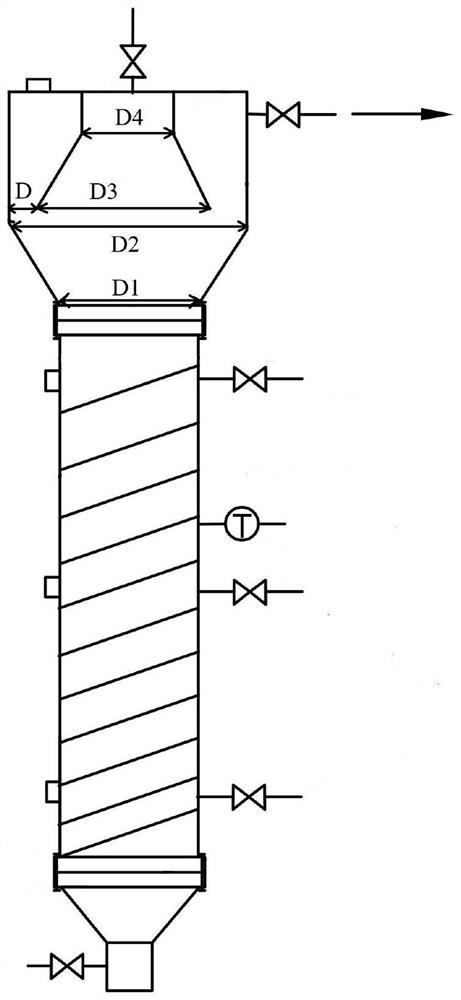

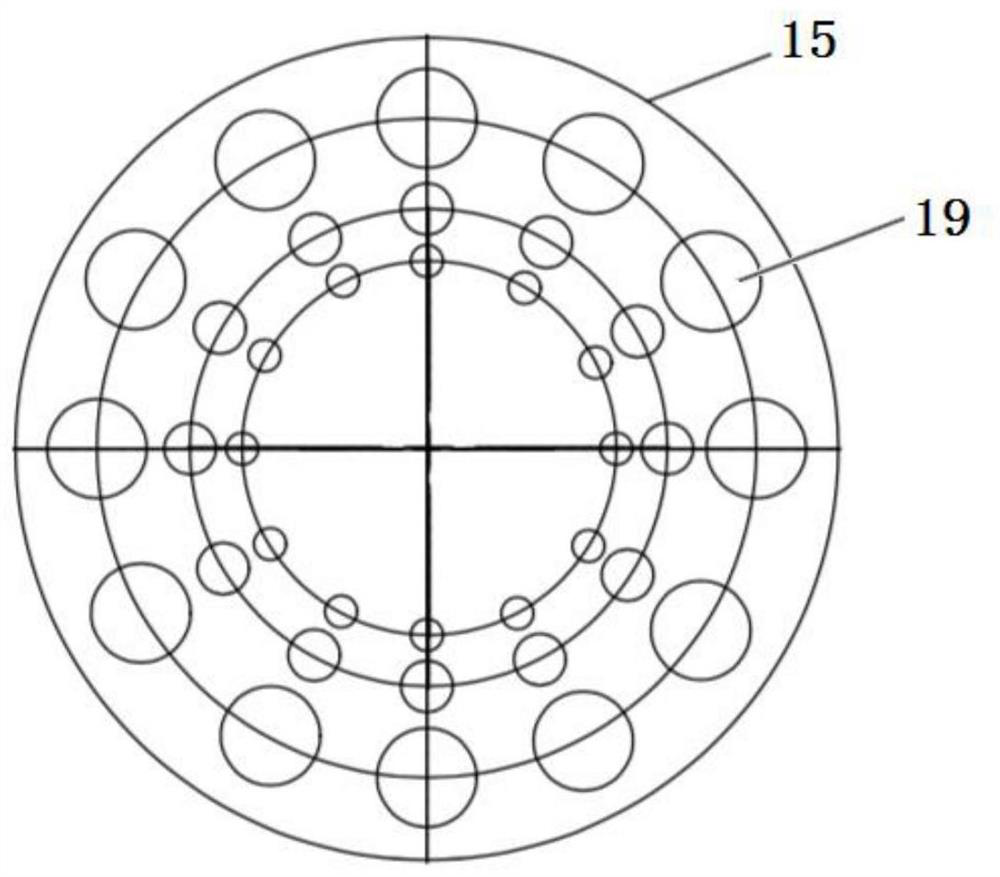

[0062] Such as figure 1 As shown, the device described in Example 1 is used, the temperature of the reactor is controlled at 35°C, the angle between the water distribution plate and the inner wall of the water inlet is 45°, and the center point of the water distribution plate is taken as the center of the circle, outside the circular range with a diameter of 0.7cm There is a water hole, and the diameter of the water hole gradually increases along the center to the edge according to three levels, which are 0.3cm, 0.6cm, and 1.0cm; the ratio of reactor height to diameter is 20:1; the volume of the reactor and the three-phase The volume ratio of the separator is 3.3:1; the ratio of the height of the reactor to the height of the three-phase separator is 8:2. The ratio of the lower cross-sectional diameter D1 to the upper cross-sectional diameter D2 of the sludge settling unit of the three-phase separator is 3:8, and the ratio of the upper cross-sectional diameter D4 to the lower c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com