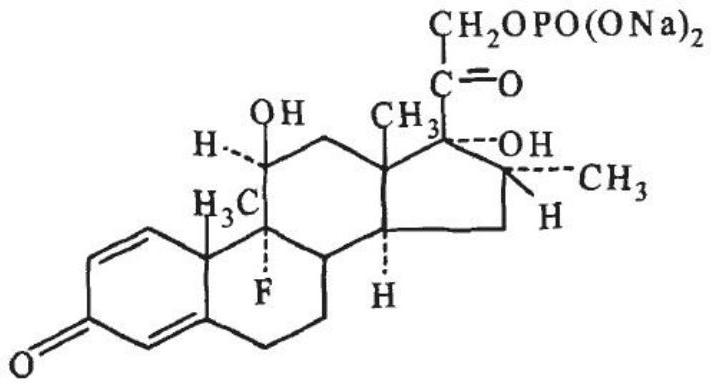

Method for efficiently removing dexamethasone sodium phosphate crystal water

A technology of dexamethasone sodium phosphate and crystal water, which is applied in the chemical industry, can solve the problems of reduced stability of preparations, white spots, and white lumps, and achieve the effects of short heating time, low heating temperature, and improved yield and quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

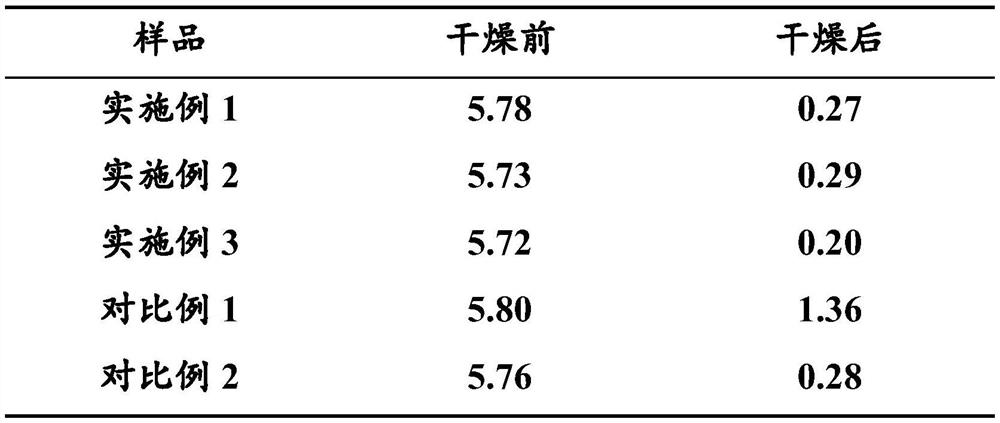

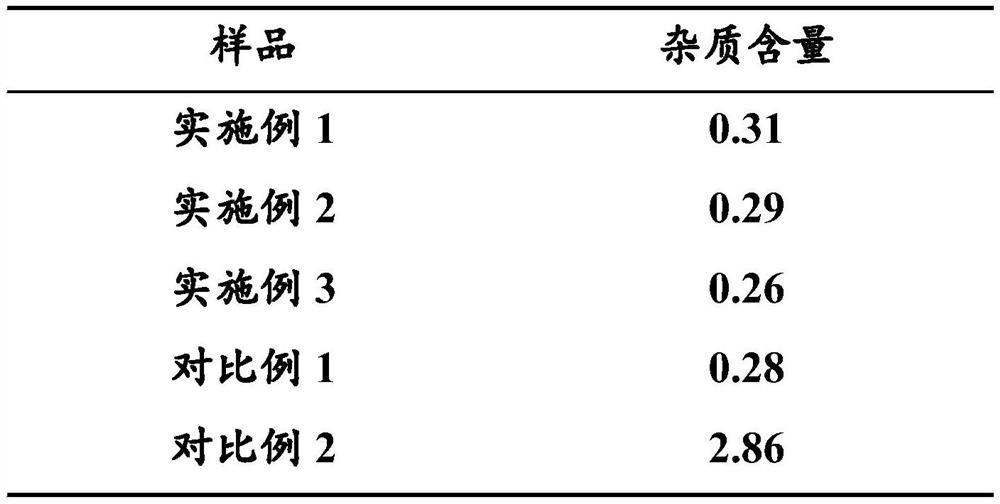

Embodiment 1

[0025] A method for efficiently removing crystal water of dexamethasone sodium phosphate, comprising the following steps:

[0026] (1) Get the dexamethasone sodium phosphate sample containing crystal water, place it in the stainless steel tray of the vacuum drying oven (the material thickness of the sample is below 8mm), close the box door, close the air release valve, open the vacuum valve, and open the vacuum pump Power and vacuum;

[0027] (2) After the vacuum degree reaches 80-120Pa, close the vacuum valve first, and then turn off the power supply of the vacuum pump;

[0028] (3) Heat, dry and dehydrate according to the following heating program: raise the temperature to 55°C and keep for 30 minutes; raise the temperature to 75°C and keep for 20 minutes; raise the temperature to 95°C and keep for 10 minutes;

[0029] (4) After heating, drying and dehydration, turn off the power, open the vent valve, and release the vacuum state;

[0030] (5) When the temperature is lower...

Embodiment 2

[0033] A method for efficiently removing crystal water of dexamethasone sodium phosphate, comprising the following steps:

[0034] (1) Get the dexamethasone sodium phosphate sample containing crystal water, place it in the stainless steel tray of the vacuum drying oven (the material thickness of the sample is below 8mm), close the box door, close the air release valve, open the vacuum valve, and open the vacuum pump Power and vacuum;

[0035] (2) After the vacuum degree reaches 80-120Pa, close the vacuum valve first, and then turn off the power supply of the vacuum pump;

[0036] (3) Heat, dry and dehydrate according to the following heating program: raise the temperature to 45°C and keep it for 50 minutes; raise the temperature to 65°C and keep it for 40 minutes; raise the temperature to 85°C and keep it for 30 minutes;

[0037] (4) After heating, drying and dehydration, turn off the power, open the vent valve, and release the vacuum state;

[0038] (5) When the temperature...

Embodiment 3

[0041] A method for efficiently removing crystal water of dexamethasone sodium phosphate, comprising the following steps:

[0042] (1) Get the dexamethasone sodium phosphate sample containing crystal water, place it in the stainless steel tray of the vacuum drying oven (the material thickness of the sample is below 8mm), close the box door, close the air release valve, open the vacuum valve, and open the vacuum pump Power and vacuum;

[0043] (2) After the vacuum degree reaches 80-120Pa, close the vacuum valve first, and then turn off the power supply of the vacuum pump;

[0044] (3) Heat, dry and dehydrate according to the following heating program: raise the temperature to 50°C and keep for 40 minutes; raise the temperature to 70°C and keep for 30 minutes; raise the temperature to 90°C and keep for 20 minutes.

[0045] (4) After heating, drying and dehydration, turn off the power, open the vent valve, and release the vacuum state;

[0046] (5) When the temperature is lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com