Flame-retardant high-strength polyethylene material based on ultraviolet crosslinking and preparation method thereof

A high-strength polyethylene and ultraviolet technology, applied in the field of polyethylene materials, can solve problems such as reducing the mechanical properties of polyethylene, and achieve the effects of excellent heat resistance stability and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

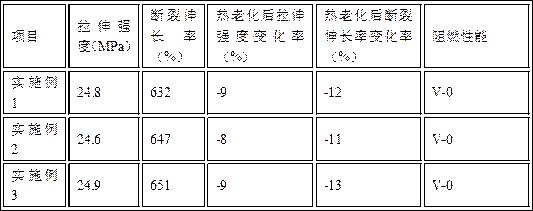

Examples

Embodiment 1

[0030] A method for preparing a flame-retardant high-strength polyethylene material based on ultraviolet crosslinking, comprising the following steps:

[0031] Step 1: Prepare materials;

[0032] Step 2: Prepare modified magnesium oxide: Mix magnesium nitrate hexahydrate, aluminum nitrate nonahydrate and citric acid, dissolve in distilled water, then add lithium salt, stir for 2 minutes, continue to add template agent, stir for 2 hours at 80°C water bath temperature, After the reaction, place it in a muffle furnace for heat treatment 3, the heat treatment temperature is 160°C, and then place it for calcination at 500°C to obtain modified magnesium oxide; wherein the lithium salt is lithium nitrate.

[0033] Step 3: Mix calcium phosphate, modified magnesium oxide, antimony oxide and zinc oxide, dissolve in absolute ethanol, stir for 20 minutes, and then dry at 80°C for 24 hours. After drying, put it in a mold and press for molding. The pressing pressure is 150MPa , pressed and...

Embodiment 2

[0038] A method for preparing a flame-retardant high-strength polyethylene material based on ultraviolet crosslinking, comprising the following steps:

[0039] Step 1: Prepare materials;

[0040] Step 2: Prepare modified magnesium oxide: Mix magnesium nitrate hexahydrate, aluminum nitrate nonahydrate and citric acid, dissolve in distilled water, then add lithium salt, stir for 2.5 minutes, continue to add template agent, stir for 1.5 minutes at 82°C water bath temperature h, heat treatment in a muffle furnace for 3.5 hours after the reaction, at a temperature of 155°C, and then calcined at 550°C to obtain modified magnesium oxide; wherein the lithium salt is lithium nitrate.

[0041] Step 3: Mix calcium phosphate, modified magnesium oxide, antimony oxide and zinc oxide, dissolve in absolute ethanol, stir for 25 minutes, and then dry at 85°C for 22 hours. After drying, place it in a mold and press for molding. The pressing pressure is 151MPa , after pressing, place it at 1325°...

Embodiment 3

[0046] A method for preparing a flame-retardant high-strength polyethylene material based on ultraviolet crosslinking, comprising the following steps:

[0047] Step 1: Prepare materials;

[0048] Step 2: Prepare modified magnesium oxide: Mix magnesium nitrate hexahydrate, aluminum nitrate nonahydrate and citric acid, dissolve in distilled water, then add lithium salt, stir for 3 minutes, continue to add template agent, stir for 1 hour at 85°C water bath temperature, After the reaction, heat treatment in a muffle furnace for 4 hours at a temperature of 150°C, and then calcined at 600°C to obtain modified magnesium oxide; wherein the lithium salt is lithium nitrate.

[0049] Step 3: Mix calcium phosphate, modified magnesium oxide, antimony oxide and zinc oxide, dissolve in absolute ethanol, stir for 30 minutes, and then dry at 90°C for 20 hours. After drying, place it in a mold and press for molding. The pressing pressure is 152MPa , pressed and placed at 1350°C for sintering, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com