Preparation method for improving yield of beta-cyclodextrin

A cyclodextrin and glucose-based technology, which is applied in the field of preparation to increase the yield of β-cyclodextrin, can solve the problems of increasing the yield of cyclodextrin, reducing product inhibition, and affecting the final yield, so as to improve the yield of enzymes and bacteria. Utilization rate, load avoidance, and yield improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention provides a preparation method for improving the yield of β-cyclodextrin, comprising the following steps:

[0021] 1) Preparation of immobilized cyclodextrin glucosyltransferase and immobilized cyclodextrin glucosyltransferase producing bacteria:

[0022] Dissolve Eudragit S-100 in ethanol solution, the concentration of Eudragit S-100 is 15-30g / L, add cyclodextrin glucosyltransferase containing 50-70U / mL and 5-10cfu / mL of cyclodextrin glucosyltransferase-producing bacteria, mix evenly, and incubate for 1-3 hours at 25-35°C and pH 6.0-8.0; after incubation, adjust the pH of the solution to <6.0 with a pH regulator, The suspension was obtained, centrifuged at 6000r / min for 30 minutes, and filtered to obtain solid microspheres: add ethanol solution to wash the microspheres, and the suspension was centrifuged at 6000r / min for 30 minutes, and the washing process was repeated three times to obtain immobilized cyclodextrin glucosyltransferase and immobilized cyc...

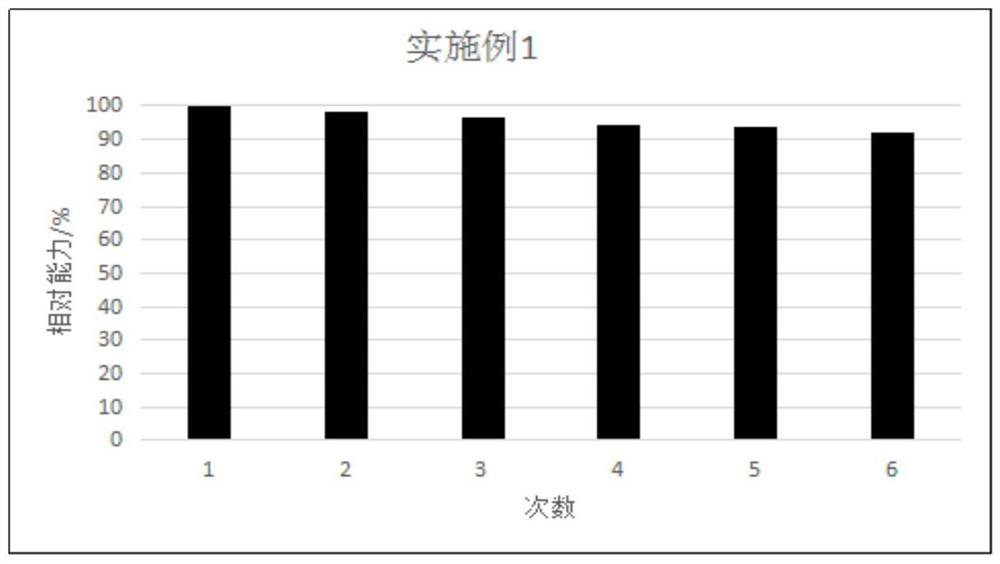

Embodiment 1

[0027] This implementation provides a preparation method for improving the yield of β-cyclodextrin, comprising the following steps:

[0028] 1) Preparation of immobilized cyclodextrin glucosyltransferase and immobilized cyclodextrin glucosyltransferase producing bacteria:

[0029] After dissolving Eudragit S-100 with ethanol solution, the concentration of Eudragit S-100 is 15g / L, and the cyclodextrin glucosyltransferase containing 50U / mL and 10cfu / mL cyclodextrin glucose are added in a volume ratio of 1:4 base transferase-producing bacteria, mix well, and incubate for 1-3 hours at 25-35°C and pH 6.0-8.0; after incubation, adjust the pH of the solution to <6.0 with ammonium sulfate solution, and let stand to obtain a suspension. Centrifuge at 6000r / min for 30 minutes and filter to obtain solid microspheres: add ethanol solution to wash the microspheres, and centrifuge the suspension at 6000r / min for 30 minutes. The washing process is repeated three times to obtain immobilized c...

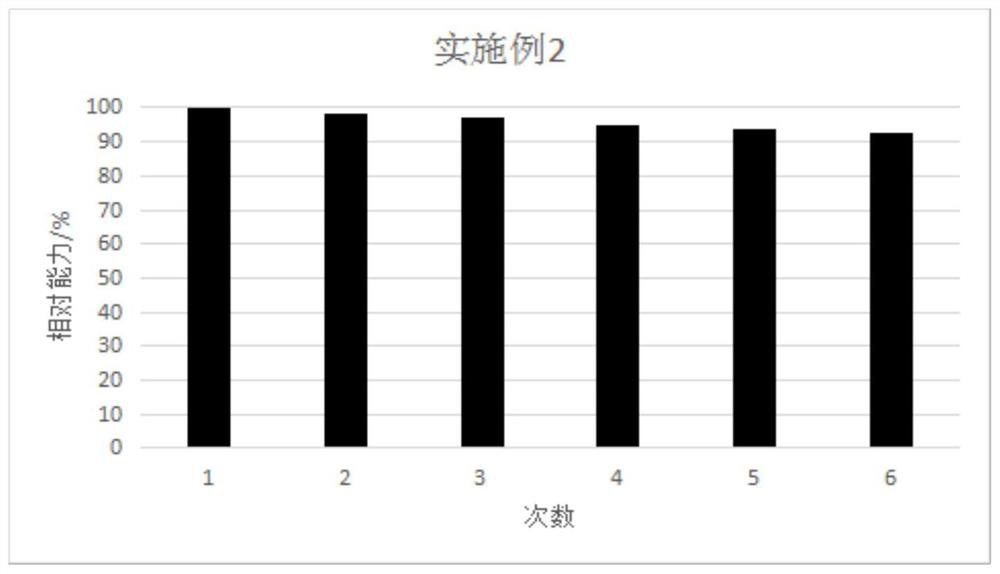

Embodiment 2

[0033] This embodiment provides a preparation method for increasing the yield of β-cyclodextrin, comprising the following steps:

[0034] 1) Preparation of immobilized cyclodextrin glucosyltransferase and immobilized cyclodextrin glucosyltransferase producing bacteria:

[0035] Dissolve Eudragit S-100 with ethanol solution, the concentration of Eudragit S-100 is 20g / L, add cyclodextrin glucosyltransferase containing 58U / mL and 9cfu / mL cyclodextrin glucosyl Transferase-producing bacteria, mix evenly, and incubate for 1-3 hours at 25-35°C, pH 6.0-8.0; after incubation, adjust the pH of the solution to <6.0 with ammonium nitrate, and let stand to obtain a suspension, 6000r / Centrifuge for 30 minutes, filter to obtain solid microspheres: add ethanol solution to wash the microspheres, and centrifuge the suspension at 6000r / min for 30 minutes, repeat the washing process three times, and obtain immobilized cyclodextrin glucosyltransferase and immobilized cyclodextrin glucose The bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com