A paint for thoroughly eliminating surface reaction layer defects of ductile iron parts

A technology of surface reaction and ductile iron parts, which is applied in the direction of coating, casting molding equipment, casting mold composition, etc., can solve the problem of failing to meet the stable quality requirements of the reaction layer of high-end safety ductile iron parts and the production of high-end safety ductile iron parts. Quality requirements, thickness reduction of flake graphite reaction layer and other issues, to achieve the effect of eliminating reaction layer defects, excellent thixotropy and rheology, and preventing surface defects of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

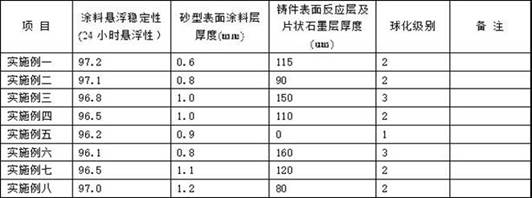

Examples

Embodiment 1

[0030] This embodiment provides a coating that completely eliminates the surface reaction layer defects of ductile iron parts. Its components and weight percentages of each component are as follows: 20% zircon powder, 30% spheroidized mixture, 2% lithium-based bentonite, thermosetting phenolic resin 2%, auxiliary agent 3%, the rest of ethanol; the nodulizing mixture is a mixture of a nodulizing agent and an inoculant, and the inoculant accounts for 50% of the weight ratio of the nodulizing agent; the particle size of the nodulizing agent and the inoculant is 50-100 mesh; the auxiliary agent is 0.5% of polyvinyl butyral, 2.5% of iron oxide red, and 0.5% of defoamer.

[0031] The particle size of the zircon powder is 250 mesh.

[0032] The particle size of the lithium-based bentonite is 350 mesh.

[0033] The particle size of the iron oxide red is 250 mesh.

[0034] The nodulizer is 2-6 rare earth magnesium ferrosilicon alloy, its composition (wt, %) is: Si43-47, Mg5.5-7.0, RE...

Embodiment 2

[0046] This embodiment provides a coating that completely eliminates the surface reaction layer defects of ductile iron parts. Its components and weight percentages of each component are as follows: 20% zircon powder, 35% spheroidized mixture, 2.5% lithium-based bentonite, thermosetting phenolic resin 2.5%, auxiliary agent 3%, the rest ethanol; the nodulizing mixture is the mixture of nodulizing agent and inoculant, and the weight ratio of inoculant accounting for nodulizing agent is 60%; the particle size of described nodulizing agent and inoculant is 50-100 mesh; the auxiliary agent is 0.5% of polyvinyl butyral, 2.5% of iron oxide red, and 0.5% of defoamer.

[0047] The particle size of the zircon powder is 250 mesh.

[0048] The particle size of the lithium-based bentonite is 350 mesh.

[0049] The particle size of the iron oxide red is 250 mesh.

[0050] The nodulizer is 2-6 rare earth magnesium ferrosilicon alloy, its composition (wt, %) is: Si43-47, Mg5.5-7.0, RE2.0-2....

Embodiment 3

[0062] This embodiment provides a coating that completely eliminates the surface reaction layer defects of ductile iron parts. Its components and weight percentages of each component are as follows: 25% of zirconium powder, 30% of spheroidized mixture, 2.5% of lithium-based bentonite, thermosetting phenolic resin 2.5%, auxiliary agent 3%, the rest ethanol; the nodulizing mixture is the mixture of nodulizing agent and inoculant, and the weight ratio of inoculant accounting for nodulizing agent is 40%; the particle size of described nodulizing agent and inoculant is 70-140 mesh; the auxiliary agent is 0.5% of polyvinyl butyral, 2.5% of iron oxide red, and 0.5% of defoamer.

[0063] The particle size of the zircon powder is 250 mesh.

[0064] The particle size of the lithium-based bentonite is 350 mesh.

[0065] The particle size of the iron oxide red is 250 mesh.

[0066] The nodulizer is 2-6 rare earth magnesium ferrosilicon alloy, its composition (wt, %) is: Si43-47, Mg5.5-7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com