Calcium-resistant concrete thickener and preparation method thereof

A thickener and concrete technology, applied in the field of calcium-resistant concrete thickener and preparation, can solve the problems of water reducing agent interference, etc., to improve the dispersion of slurry, increase zeta potential value, improve workability and workability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

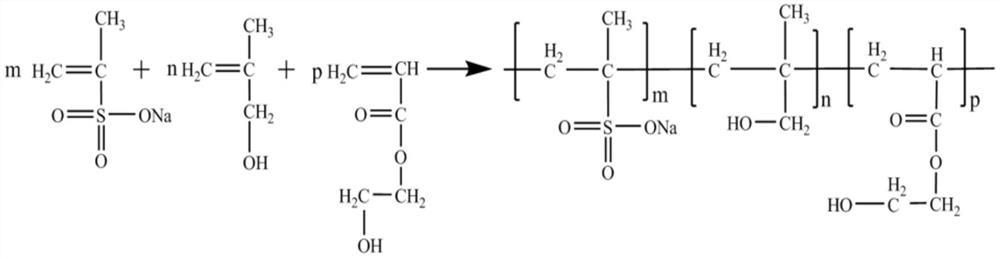

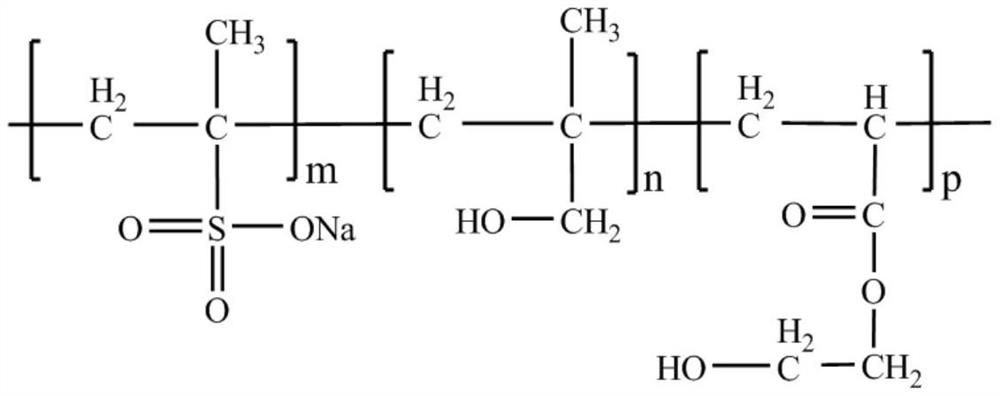

Method used

Image

Examples

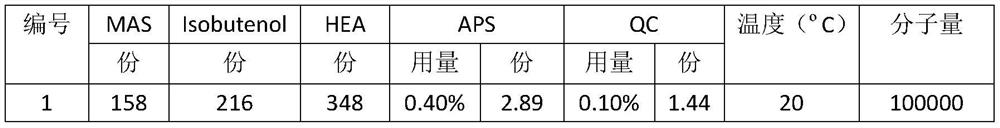

Embodiment 1-14

[0034] Mix sodium methacrylate sulfonate (MAS), isobutenol (Isobutenol), and hydroxyethyl acrylate (HEA) to prepare a solution with a mass fraction of 10% (note: solution A); the initiator is ammonium persulfate (APS ), its dosage is 0.3-0.5% of the total mass of the monomer (sodium methacrylic acid sulfonate, isobutenol, hydroxyethyl acrylate), and it is prepared into a solution with a mass fraction of 1% (note: solution B), and evenly divides Three parts; the chain transfer agent is mercaptoethanol (QC), and its consumption is 0.1-0.3% of the total mass of the monomers, prepared into a 1% solution (note: solution C), and divided into three parts. Stir the A solution at 25±5°C, add the above B and C solutions to the A solution three times, and the interval between each two is 30min. Finally, the mixed solution was stirred for 30 minutes to obtain the anti-calcium concrete thickener of the present invention. Each embodiment thickener ratio is shown in table 1; Concrete ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com