Layered double hydroxide composite material and preparation method and application thereof

A layered bimetal and hydroxide technology, applied in the field of environmental governance, can solve the problems of small distance between layers, few effective functional groups, low adsorption efficiency, etc., and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] This embodiment provides a method for preparing a layered double metal hydroxide composite material, the preparation method comprising the following steps:

[0064] 0.5g Mg-Al-CO 3 2- -LDH and 0.5g tetrasodium iminodisuccinate were dispersed in degassed deionized water to form a suspension, stirred at 20°C for 1440min; after the intercalation reaction, solid-liquid separation was performed, followed by washing with degassed deionized water and acetone, The layered double metal hydroxide composite material was obtained after vacuum drying.

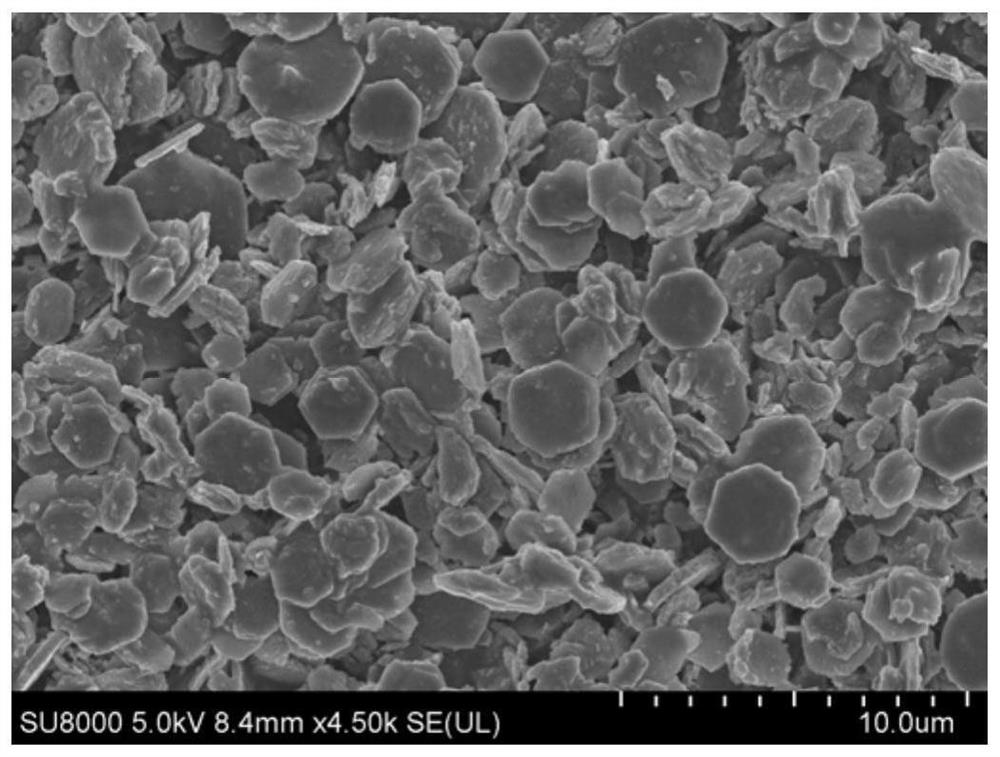

[0065] The SEM image of the resulting layered double metal hydroxide composite figure 1 shown.

[0066] Mg-Al-CO described in this example 3 2- -LDH is the Mg-Al layered double metal hydroxide prepared by the hydrothermal method, and the hydrothermal method specifically includes the following steps:

[0067] Mix magnesium nitrate, aluminum nitrate and urea according to the molar ratio of 2:1:10 to obtain a mixed solution. The c...

Embodiment 2

[0069] This embodiment provides a method for preparing a layered double metal hydroxide composite material, the preparation method comprising the following steps:

[0070] 0.5g Mg-Al-CO 3 2- -LDH and 1g of tetrasodium iminodisuccinate were dispersed in degassed deionized water to form a suspension, and stirred at 10°C for 2880 min; after the intercalation reaction, solid-liquid separation was performed, followed by washing with degassed deionized water and acetone, vacuum After drying, the layered double metal hydroxide composite material is obtained.

[0071] Mg-Al-CO described in this example 3 2- -LDH is the Mg-Al layered double metal hydroxide prepared by the hydrothermal method, and the hydrothermal method specifically includes the following steps:

[0072] Mix magnesium nitrate, aluminum nitrate and urea according to the molar ratio of 1.8:1:8 to obtain a mixed solution. The concentration of magnesium nitrate in the mixed solution is 0.09mol / L; hydrothermal reaction is...

Embodiment 3

[0074] This embodiment provides a method for preparing a layered double metal hydroxide composite material, the preparation method comprising the following steps:

[0075] 0.5g Mg-Al-CO 3 2- -LDH and 1.5g of tetrasodium iminodisuccinate were dispersed in degassed deionized water to form a suspension, stirred at 80°C for 2100 min; after the intercalation reaction, solid-liquid separation was performed, followed by washing with degassed deionized water and acetone, The layered double metal hydroxide composite material was obtained after vacuum drying.

[0076] Mg-Al-CO described in this example 3 2- -LDH is the Mg-Al layered double metal hydroxide prepared by the hydrothermal method, and the hydrothermal method specifically includes the following steps:

[0077] Mix magnesium nitrate, aluminum nitrate and urea according to the molar ratio of 2.2:1:12 to obtain a mixed solution. The concentration of magnesium nitrate in the mixed solution is 0.11mol / L; hydrothermal reaction i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com