A kind of antimony sulfide-based composite material and its preparation method and application

A composite material, antimony sulfide-based technology, applied in electrochemical generators, active material electrodes, structural parts, etc., can solve problems such as poor conductivity and volume change of lithium intercalation, achieve improved conductivity, simple overall process, and solve the problem of electrical conductivity. poor sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The second aspect of the present invention provides a method for preparing an antimony sulfide-based composite material, preferably the method for preparing the antimony sulfide-based composite material described in the first aspect of the present invention, and the method includes the following steps:

[0054] Step 1. Process natural stibnite to form product A.

[0055] According to the present invention, in step 1, the processing of natural stibnite includes:

[0056] Step 1.1, adding natural stibnite into the medium to obtain a mixture;

[0057] According to the present invention, in step 1.1, the medium is an aqueous solution of sulfide salt, and the sulfide salt is preferably selected from one or more of sodium sulfide, potassium sulfide and ammonium sulfide.

[0058] In the present invention, the main component of natural stibnite is antimony sulfide, and adding natural stibnite into the aqueous solution of sulfide salt can make antimony sulfide react with sulfid...

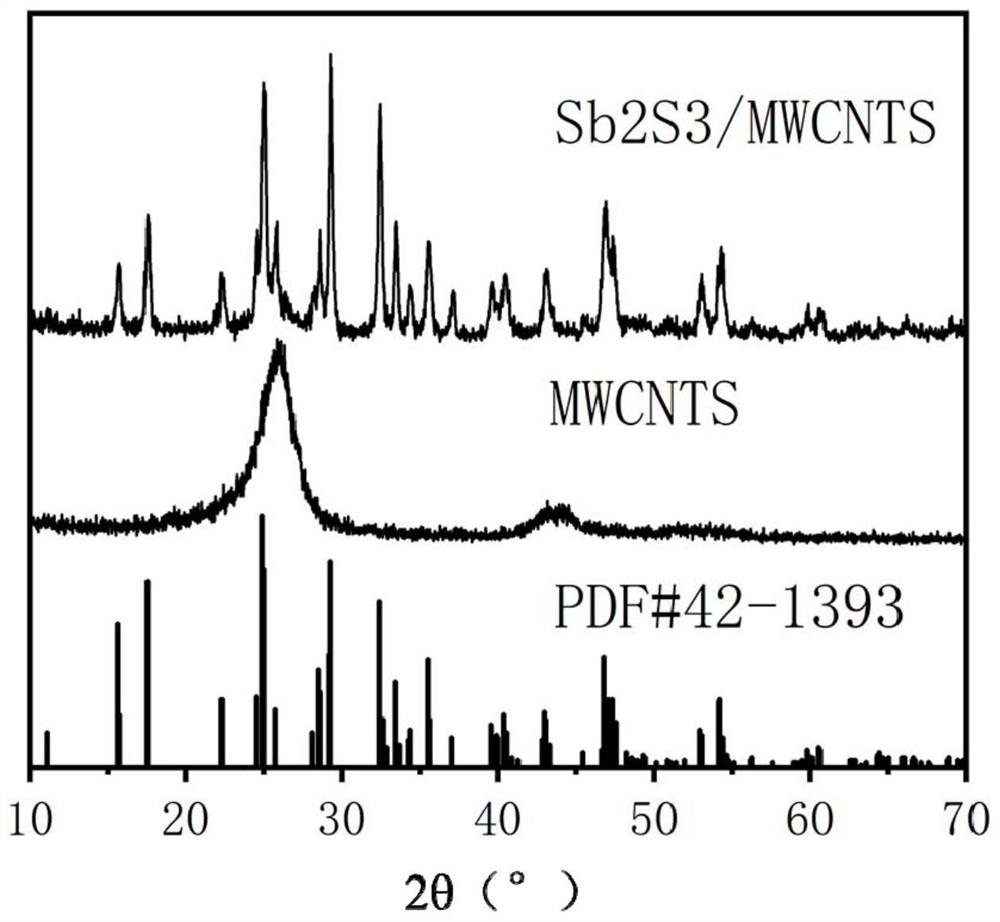

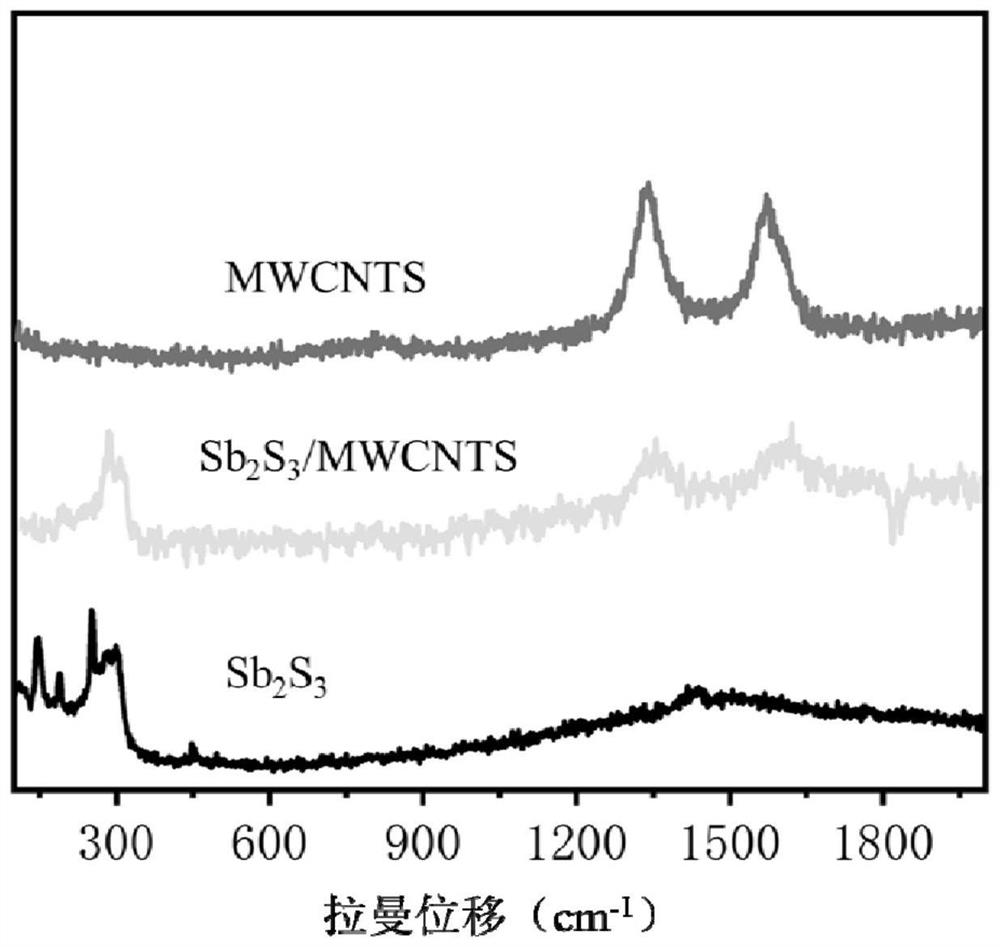

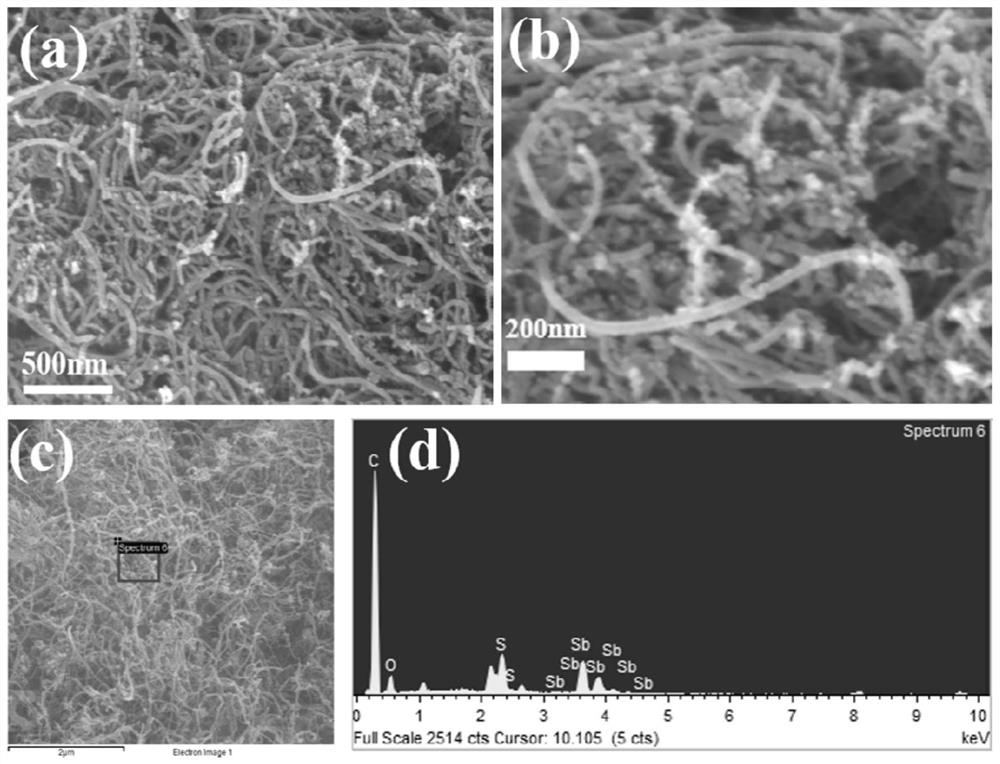

Embodiment 1

[0119] Stir and dissolve 16.9g of natural stibnite in 100ml of sodium sulfide solution with a concentration of 10mmol / L, and centrifuge at 8000r after standing for 1 hour to obtain solution A and stibnite residue (stibnite residue can be recycled);

[0120] Add 0.5 g of multi-walled carbon nanotubes (MWCNTS) to 40 ml of H 2 SO 4 :HNO 3 (3:1) in the solution, sonicated for 2h, then centrifuged at 12000r for 5min, centrifuged 3 times, dried the obtained solid and added to 0.1mol / L, 250ml of polydiallyldimethylammonium chloride (PDDA ) after centrifugation to obtain the treated multi-walled carbon nanotubes, and the treated multi-walled carbon nanotubes are dispersed in water to obtain a 5 mg / mL multi-walled carbon nanotube suspension;

[0121] Add 5ml of 5mg / mL multi-walled carbon nanotube suspension to 50ml of solution A, and ultrasonically process for 1 minute to obtain a mixed solution;

[0122] The obtained mixed solution was fully mixed with 30 mmol DMF solution, and the...

Embodiment 2

[0129] Stir and dissolve 16.9g of natural stibnite in 100ml of sodium sulfide solution with a concentration of 10mmol / L, and centrifuge at 8000r after standing for 1 hour to obtain solution A and stibnite residue (stibnite residue can be recycled);

[0130] Add 0.3g of MWCNTs to 40ml of H 2 SO 4 :HNO 3 (3:1) in the solution, ultrasonicated for 2h, then centrifuged at 12000r for 5min, dried and added to 0.1mol / L polydiallyldimethylammonium chloride (PDDA) for treatment and centrifugation to obtain the treated walled carbon nanotubes, dispersing the treated multi-walled carbon nanotubes in water to obtain a 5 mg / mL multi-walled carbon nanotube suspension;

[0131] Add 5ml of 5mg / mL multi-walled carbon nanotube suspension to 50ml of solution A, and ultrasonically process for 1 minute to obtain a mixed solution;

[0132] The obtained mixture was fully mixed with 100 mmol DMF, then added to a hydrothermal kettle with a total of 80 ml to 100 ml of ultrapure water, placed in a bla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com