PMSM current prediction control method based on SD-MPM

A current prediction and control method technology, which is applied in the direction of motor generator control, electronic commutation motor control, control system, etc., can solve the problems of unfixed switching frequency, inability to control noise and harmonics, and large amount of calculation, etc., to achieve good results. The effect of sampling delay and calculation delay, improving steady-state error, and optimizing control bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The concept of the current predictive control algorithm is simple and easy to understand, easy to implement, and convenient to debug. However, the nature of its model-based algorithm determines that the control performance is highly sensitive to factors such as model parameter mismatch and sampling delay. Model parameter mismatch and sampling delay It will affect the control performance of the system, and even make the system diverge, so the optimization algorithm considering the sampling delay and model parameter mismatch has important practical significance.

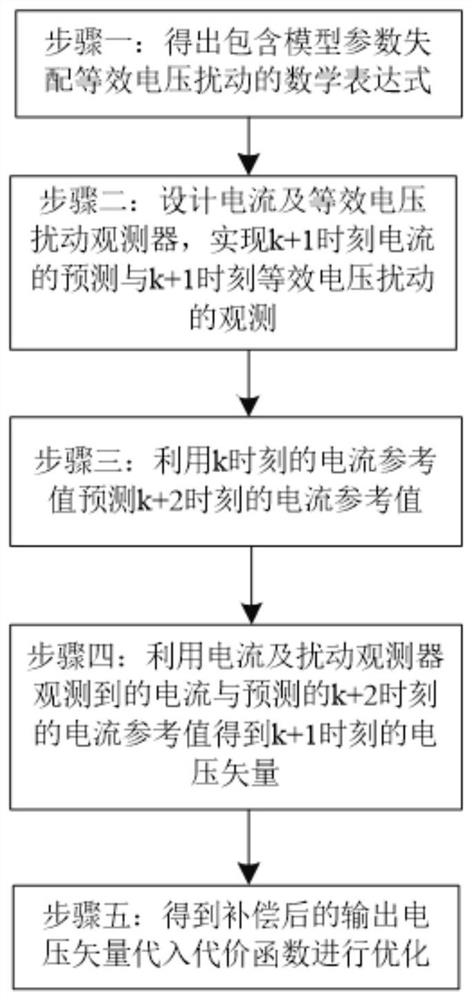

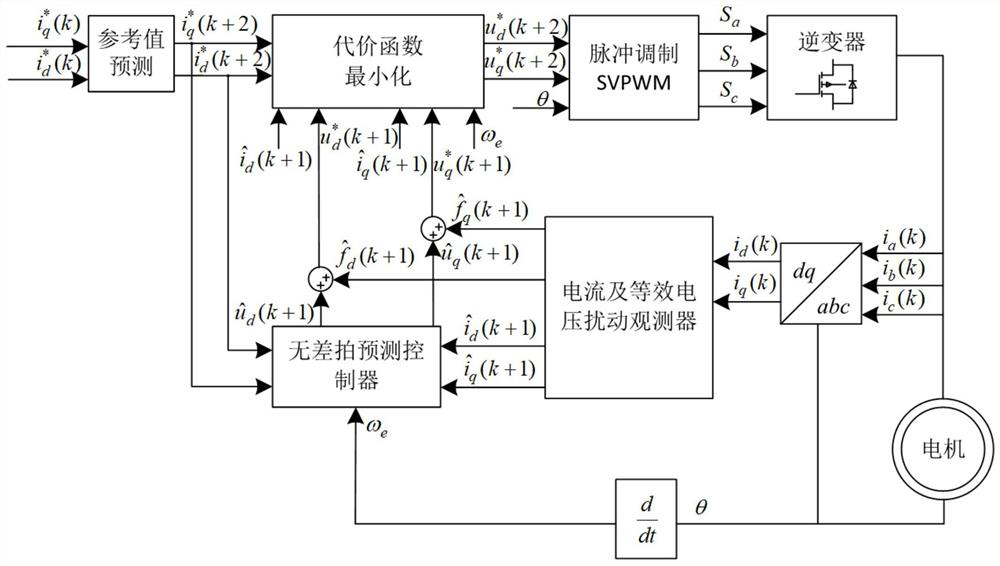

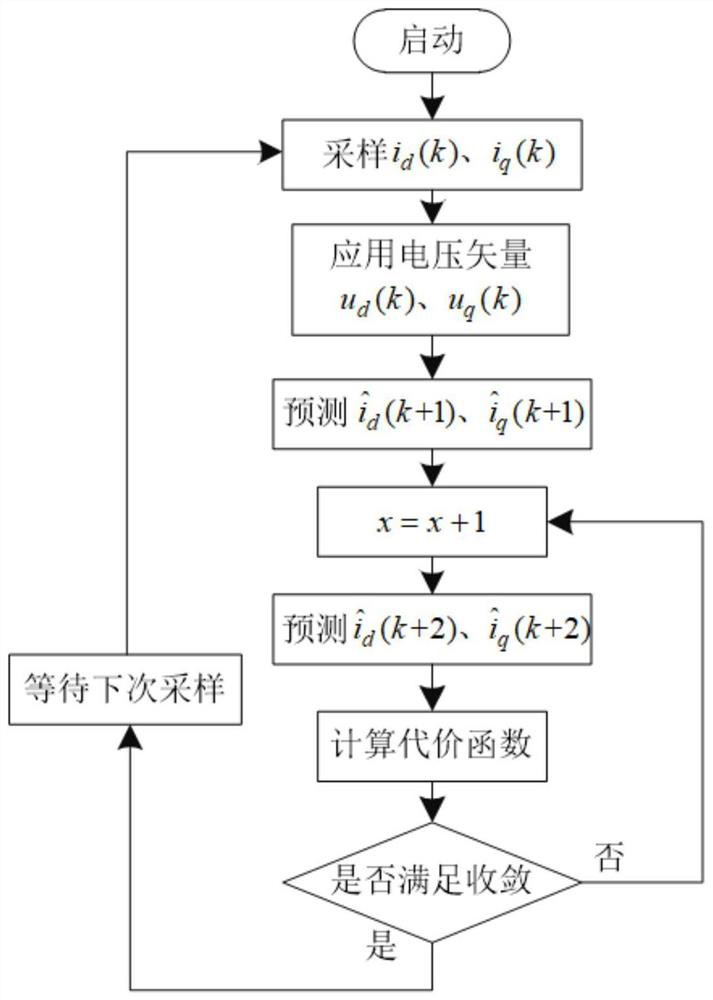

[0047] refer to Figure 1 ~ Figure 4 For the first embodiment of the present invention, a PMSM current predictive control method based on SD-MPM (SampleDelay sampling delay, Model parameter mismatch model parameter mismatch) is provided, including:

[0048] S1: Calculate the voltage state equation of the permanent magnet synchronous motor, and obtain the mathematical expression of the equivalent voltage disturba...

Embodiment 2

[0088] Preferably, the existing permanent magnet synchronous motor deadbeat predictive control method is realized based on a predictable iron loss equivalent circuit model, and the method collects the actual speed ω of the permanent magnet synchronous motor at the current k moment in real time m (k) and reference speed ω * m , input the result of the comparison operation between the two into the PI controller module, and output the reference currents of the d-axis and q-axis through the PI controller module, and establish the predictable iron loss equivalent circuit model of the permanent magnet synchronous motor. The beat predictive control calculates the d-axis and q-axis reference voltages at k+1 time, and performs Park inverse transformation on the obtained d-axis and q-axis reference voltages to obtain the voltage component v of the permanent magnet synchronous motor in the α-β coordinate system α and v β , the voltage component v α and v β The switching signal of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com