Preparation method of silicon carbide fiber reinforced silicon carbide ceramic-based composite material

A silicon carbide ceramic matrix and silicon carbide fiber technology, which is applied in the field of preparation of structural composite materials, can solve the problems of high modulus of SiC fibers, affecting the mechanical properties of composite materials, and being difficult to stitch operations, so as to reduce the preparation cycle and cost, improve the The effect of interlayer damage tolerance and improved suture efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

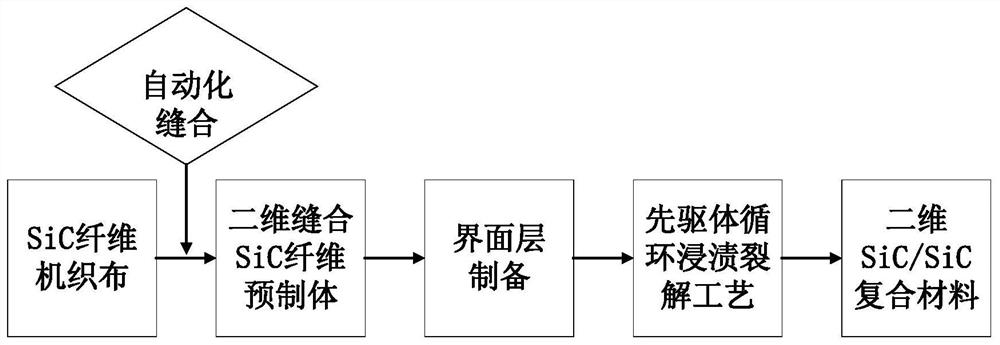

[0027] The sewing equipment used in this example is the advanced automatic numerical control sewing system produced by the original German KSL company. Continuous SiC fiber is used as the suture to carry out two-dimensional automatic sewing of SiC fiber plain weave, and the subsequent PIP (impregnation and cracking) process is used to densify SiC. / SiC composite material, specifically including the following steps:

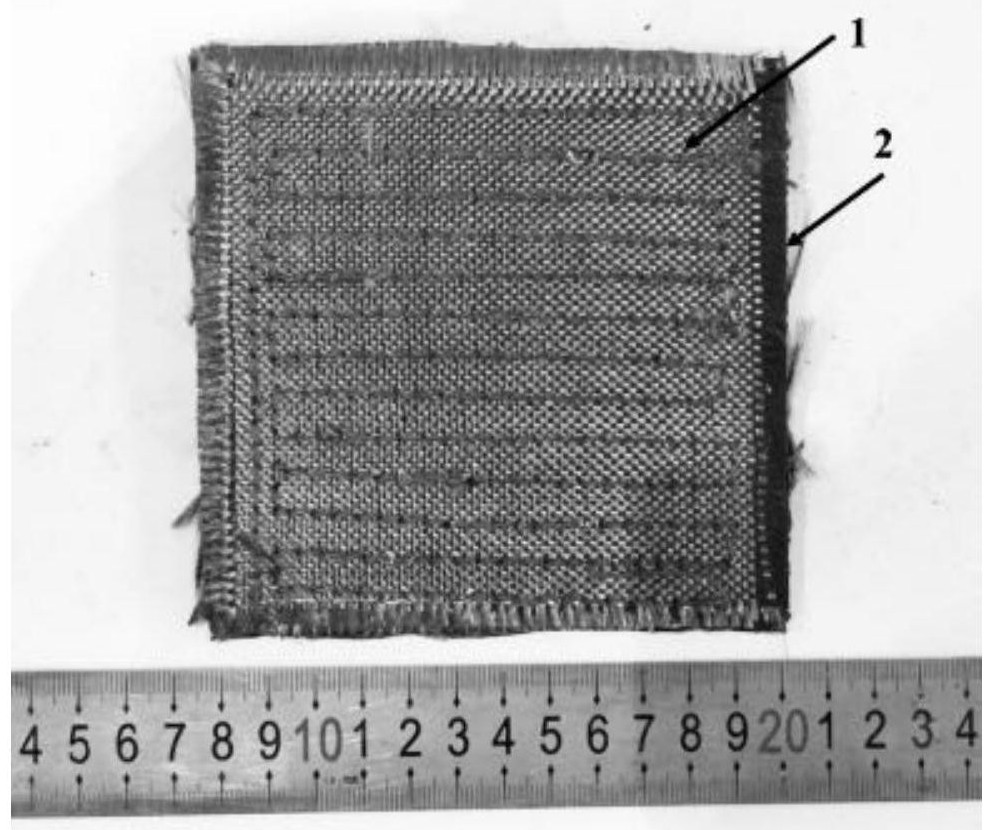

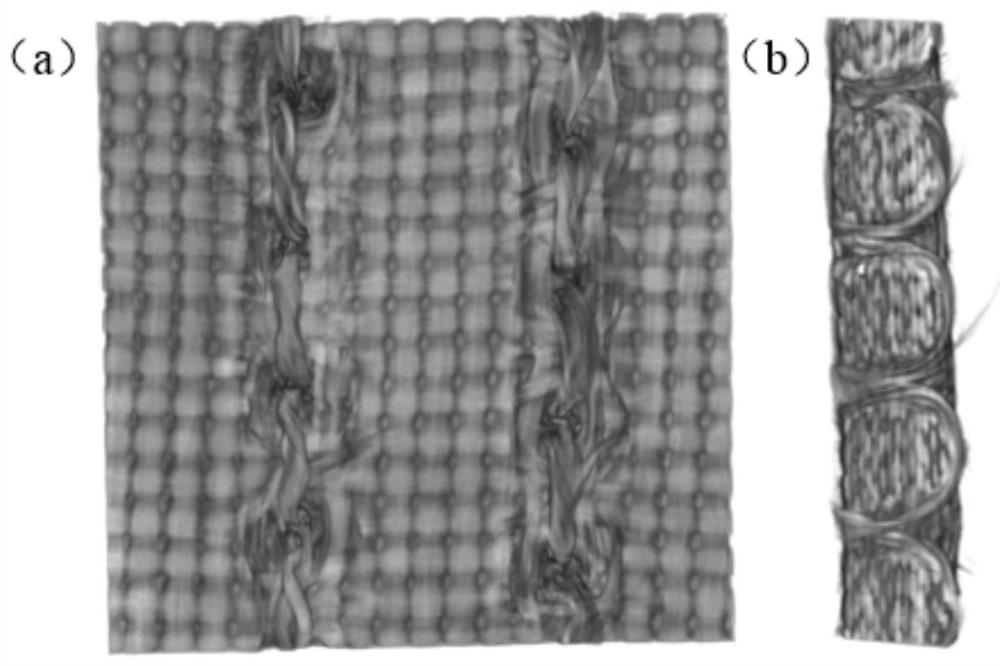

[0028] (1) Preparation of two-dimensional SiC fiber prefabricated body: SiC fiber woven fabric is selected as plain weave, and the number of layers of SiC fiber plain weave required is calculated according to the fiber volume fraction of 45% and thickness of 3 mm; The layers are fixed on the automatic numerical control suture system, using the lock stitching method, the suture line is made of SiC fiber (0.5k domestic second-generation SiC fiber), and the suture system is used for automatic suture to obtain a two-dimensional SiC fiber prefabricated body;

[0029] (...

Embodiment 2

[0032] The sewing equipment used in this example is the advanced automatic numerical control sewing system produced by the original German KSL company. Continuous SiC fiber is used as the suture to carry out two-dimensional automatic sewing of SiC fiber plain weave, and the subsequent PIP (impregnation and cracking) process is used to densify SiC. / SiC composite material, specifically including the following steps:

[0033] (1) Preparation of two-dimensional SiC fiber prefabricated body: SiC fiber woven fabric is selected from twill fabric, according to the fiber volume fraction of 45%, and the thickness is 3mm, calculate the number of layers of SiC fiber twill fabric required; stack multiple layers of twill fabric and fix On the automatic numerical control suture system, the chain suture method is adopted, and the suture thread is SiC fiber (1k domestic third-generation SiC fiber), and the suture system is used for automatic suture to obtain a two-dimensional SiC fiber prefabr...

Embodiment 3

[0037] The sewing equipment used in this example is the advanced automatic numerical control sewing system produced by the original German KSL company. Continuous SiC fiber is used as the suture to carry out two-dimensional automatic sewing of SiC fiber plain weave, and the subsequent PIP (impregnation and cracking) process is used to densify SiC. / SiC composite material, specifically including the following steps:

[0038] (1) Preparation of two-dimensional SiC fiber prefabricated body: SiC fiber woven fabric is selected as satin cloth, according to the fiber volume fraction is 45%, and the thickness is 3mm, calculate the required number of layers of SiC fiber satin cloth; satin cloth Stack multiple layers and fix them on the automatic numerical control suturing system, adopt the chain stitching method, use SiC fiber (0.8k domestic second-generation SiC fiber) as the suture thread, and use the suture system to perform automatic suture to obtain a two-dimensional SiC fiber pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com