A Transition Metal Modified Pyridine Nitrogen Conjugated Microporous Polymer Composite Photocatalyst

A composite catalyst, conjugated polymer technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of no universality, complex operation, preparation The problem of high cost, to achieve the effect of simple equipment, simple operation and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

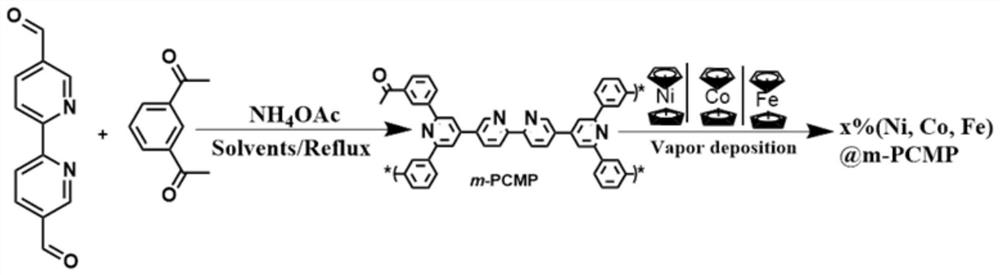

Method used

Image

Examples

Embodiment 1

[0045] (1) 0.636g of 2,2'-bipyridyl-5,5'-dicarbaldehyde, 0.973g of 1,3-diacetylbenzene and 6.9g of ammonium acetate were added to a 250mL round bottom flask;

[0046] (2) Add 150 mL of pyridine to the round bottom flask in step (1), and stir at room temperature for 20 min until the solid matter is completely dissolved;

[0047] (3) After the solid matter is dissolved, put the round-bottomed flask in step (2) into an oil bath at 115° C. to react for 24 hours, and wash with suction to obtain powder;

[0048] (4) Wash the obtained powder in deionized water and chloroform at 60° C. for 24 hours in sequence, filter with suction, and dry in a vacuum oven for 72 hours to obtain a pyridine nitrogen-based conjugated microporous polymer;

[0049] The polymer structural formula of the pyridine nitrogen-based conjugated microporous polymer prepared in step (4) is:

[0050]

[0051] (5) Nickelocene and the obtained pyridyl nitrogen-based conjugated microporous polymer are put into the tu...

Embodiment 2

[0059] (1) 0.636g of 2,2'-bipyridyl-5,5'-dicarbaldehyde, 0.973g of 1,3-diacetylbenzene and 6.9g of ammonium acetate were added to a 250mL round bottom flask;

[0060] (2) Add 150 mL of pyridine to the round bottom flask in step (1), and stir at room temperature for 20 min until the solid matter is completely dissolved;

[0061] (3) After the solid matter is dissolved, put the round-bottomed flask in step (2) into an oil bath at 115° C. to react for 24 hours, and wash with suction to obtain powder;

[0062] (4) Wash the obtained powder in deionized water and chloroform at 60° C. for 24 hours in sequence, filter with suction, and dry in a vacuum oven for 72 hours to obtain a pyridine nitrogen-based conjugated microporous polymer;

[0063] (5) Put the ferrocene and the obtained pyridine nitrogen-based conjugated microporous polymer into the tube furnace according to the mass percentage of 30wt%, and in the high-purity nitrogen (99.999%) atmosphere, at 2 ℃ / minn The heating rate i...

Embodiment 3

[0066] (1) 0.636g of 2,2'-bipyridyl-5,5'-dicarbaldehyde, 0.973g of 1,3-diacetylbenzene and 6.9g of ammonium acetate were added to a 250mL round bottom flask;

[0067] (2) Add 150 mL of pyridine to the round bottom flask in step (1), and stir at room temperature for 20 min until the solid matter is completely dissolved;

[0068] (3) After the solid matter is dissolved, put the round-bottomed flask in step (2) into an oil bath at 115° C. to react for 24 hours, and wash with suction to obtain powder;

[0069] (4) Wash the obtained powder in deionized water and chloroform at 60° C. for 24 hours in sequence, filter with suction, and dry in a vacuum oven for 72 hours to obtain a pyridine nitrogen-based conjugated microporous polymer;

[0070] (5) Put the cobaltocene and the obtained pyridine nitrogen-based conjugated microporous polymer into the tube furnace according to the mass percentage of 30wt%. The heating rate is to raise the temperature to 150° C., keep the temperature for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com