Production process of blueberry jam wine

The technology for blueberry jam and production process is applied in the field of fermented wine, which can solve the problems of unstable nutritional system and decrease of nutrients in wine, and achieve the effects of abundant pores, stable nutrients in wine liquid, and increased dissolution rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

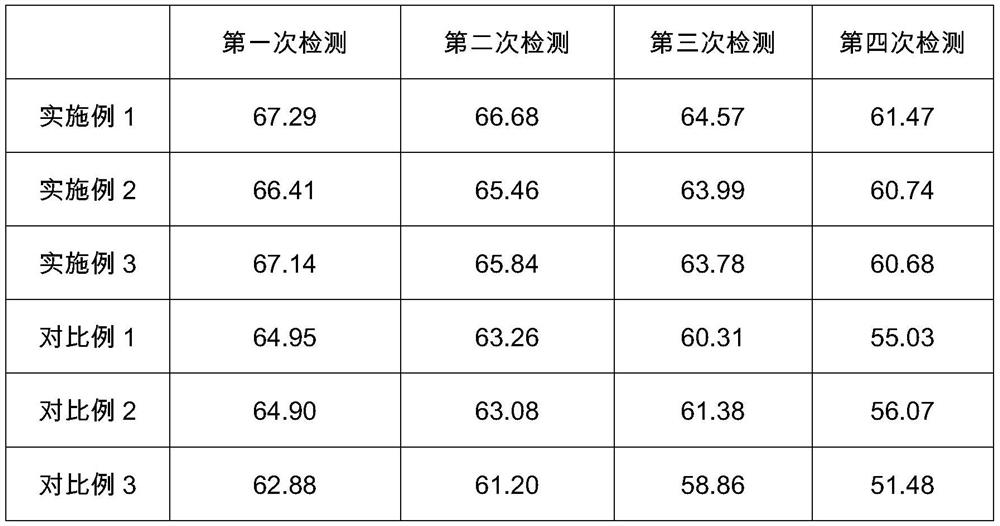

Embodiment 1

[0030] A kind of blueberry jam wine production technology, comprises the following steps:

[0031] (1) Raw material preparation: select fully ripe blueberry fruit as raw material;

[0032] (2) Picking: picking out damaged and softened fruits;

[0033] (3) Cleaning: the fruit is cleaned with a special blueberry fruit cleaning machine and drained;

[0034] (4) Broken: adopt stainless steel crusher to crush to sauce shape, pump into temperature-controlled fermenter, obtain blueberry fermented liquid; The sieve hole of described stainless steel crusher is 40 orders;

[0035] (5) Component adjustment: detect the sugar content and acidity of the raw materials, adjust the sugar content of the blueberry fermented liquid to 20°, and adjust the acidity to pH4; the reagents used for the sugar content adjustment are fructose, galactose, and glucose with a mass ratio of 3:1:20 The mixed sugar prepared; the acidity adjustment reagent is citric acid;

[0036] (6) Alcoholic fermentation: p...

Embodiment 2

[0042] A kind of blueberry jam wine production technology, comprises the following steps:

[0043] (1) Raw material preparation: select fully ripe blueberry fruit as raw material;

[0044] (2) Picking: picking out damaged and softened fruits;

[0045] (3) Cleaning: the fruit is cleaned with a special blueberry fruit cleaning machine and drained;

[0046] (4) Broken: adopt stainless steel crusher to crush to sauce shape, pump into temperature-controlled fermenter, obtain blueberry fermented liquid; The sieve hole of described stainless steel crusher is 40 orders;

[0047] (5) Component adjustment: detect the sugar content and acidity of the raw materials, adjust the sugar content of the blueberry fermented liquid to 21°, and adjust the acidity to pH7; the reagents used for the sugar content adjustment are fructose, galactose, and glucose with a mass ratio of 5:1:30 The mixed sugar prepared; the acidity adjustment reagent is citric acid;

[0048] (6) Alcoholic fermentation: a...

Embodiment 3

[0054] A kind of blueberry jam wine production technology, comprises the following steps:

[0055] (1) Raw material preparation: select fully ripe blueberry fruit as raw material;

[0056] (2) Picking: picking out damaged and softened fruits;

[0057] (3) Cleaning: the fruit is cleaned with a special blueberry fruit cleaning machine and drained;

[0058] (4) Broken: adopt stainless steel crusher to crush to sauce shape, pump into temperature-controlled fermenter, obtain blueberry fermented liquid; The sieve hole of described stainless steel crusher is 40 orders;

[0059] (5) Component adjustment: detect the sugar content and acidity of the raw materials, adjust the sugar content of the blueberry fermented liquid to 21°, and adjust the acidity to pH4; the reagents used for the sugar content adjustment are fructose, galactose, and glucose with a mass ratio of 5:1:27 The mixed sugar prepared; the acidity adjustment reagent is citric acid;

[0060] (6) Alcoholic fermentation: a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com