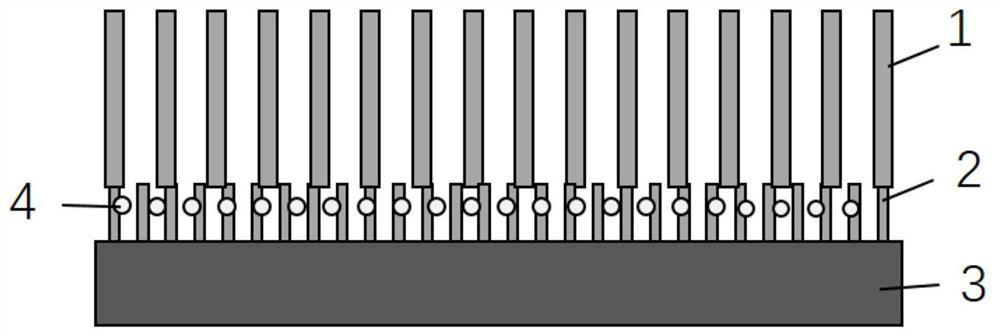

Hydrogen evolution electrode and preparation and application thereof

A hydrogen evolution electrode, nickel hydroxide technology, applied in the direction of electrode, electrode shape/type, electrolysis process, etc., can solve the problem of electrode polarization performance decline, poor conductivity, etc., to achieve reduced ohmic polarization, good stability, and improved reaction. active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

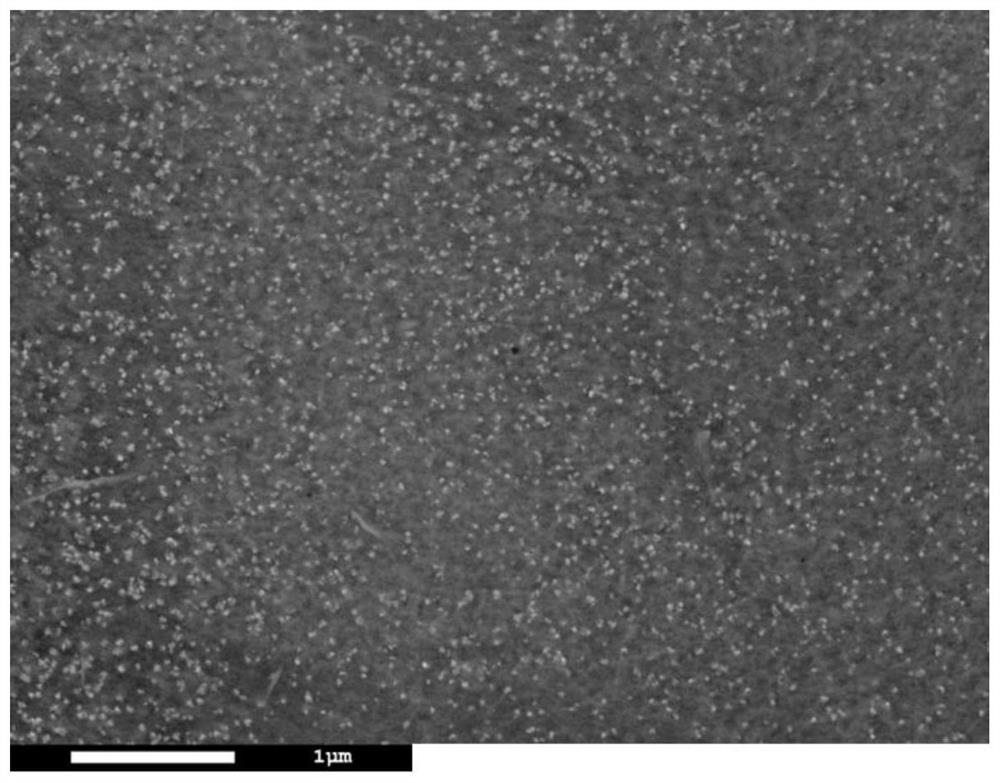

[0032] Nickel foam with a thickness of 1.6mm (surface density is 250g / cm 2 ) sheet cut into an effective area of 1 × 2cm 2 Rectangular, respectively by acetone ultrasonic cleaning 15min, 3M hydrochloric acid ultrasonic cleaning 15min, deionized water ultrasonic cleaning 3min, repeat the deionized water ultrasonic cleaning process 3-5 times (here 3 times), in the final concentration of 0.05mM chlorine 3 mL of a mixed solution of nickel chloride and sodium chloride with a final concentration of 0.8 mM, adjusted to pH 4 with 3 M hydrochloric acid, and reacted at 60° C. for 1 h. The obtained electrode was deposited in 3 mL of chloroplatinic acid with a platinum concentration of 10 μg / mL at a pH of 3 (adjusted with 3M hydrochloric acid) at 40° C. for 1 h, and then dried at 60° C. before use. Platinum nanoparticles are particles with an average particle diameter of about 60nm. This type of particle is composed of platinum particles with an average diameter of 3.8nm. The amount i...

Embodiment 2

[0034] With the preparation process of Example 1, the difference from Example 1 is that the chloroplatinic acid in Example 1 is changed to chloroiridic acid, and other conditions are unchanged. Iridium nanoparticles distribution see Figure 4 , as can be seen from the figure, the average particle diameter of iridium nanoparticles is about 110nm, and these particles are aggregated by smaller nanoparticles (diameter 2-10nm). One side of the outer surface area) The mass loading capacity of iridium particles on the nickel foam is 14.3 μg / cm 2 , its hydrogen evolution performance is shown in Figure 8 with Figure 9 , the performance of electrodes applied to magnesium / seawater batteries see Figure 11 . The results show that the hydrogen evolution performance of the electrode under neutral conditions and the stability in the magnesium / water battery are similar to those of the platinum-modified electrode in Example 1.

Embodiment 3

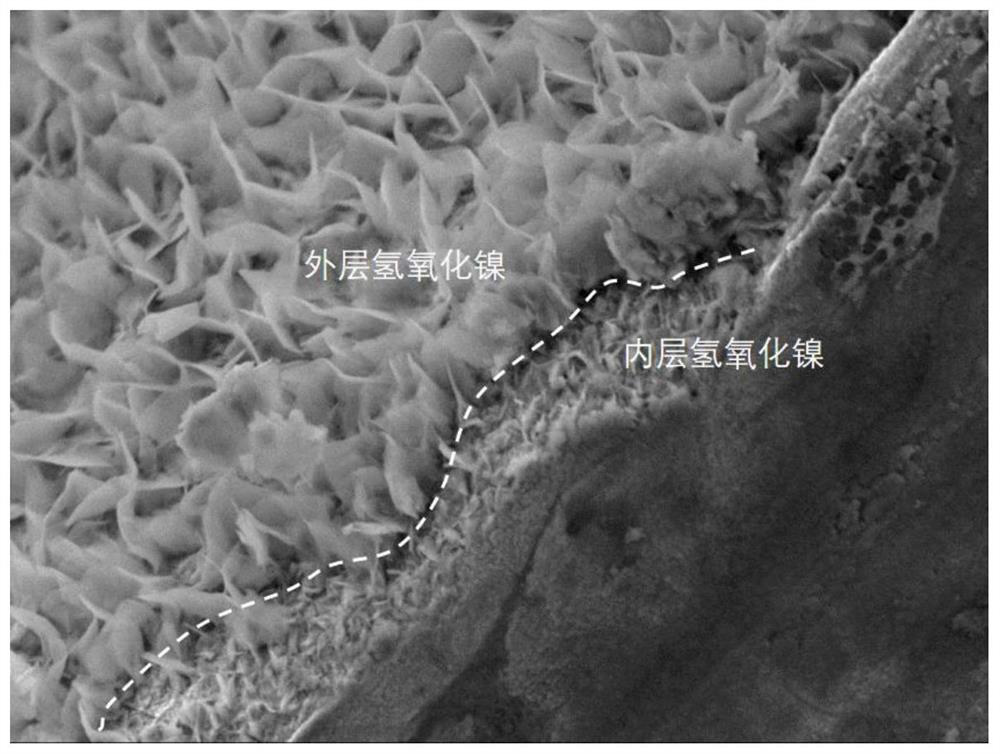

[0036] Same as the preparation process of Example 1, the electrode heating time for preparing nickel hydroxide modified nickel foam in Example 1 is increased to 25h (no longer within the protection range), and other conditions remain unchanged. Its shape and structure see Figure 5 , hydrogen evolution performance see Figure 8 with Figure 9 , the performance of electrodes applied to magnesium / seawater batteries see Figure 11 . The results show that the thickness of the nickel hydroxide flake film on the surface of the electrode increases obviously, and the ohmic polarization of the electrode increases due to the increase of the thickness of the nickel hydroxide, which leads to an increase in the polarization of the electrode at a large current, and the deterioration of the electrode performance. The thickness of nickel hydroxide on the electrode surface must be controlled by the reaction time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com