Method for amino acid-assisted wet chemical synthesis of niobate hydrate powder material and obtained material

A powder material, niobate technology, applied in chemical instruments and methods, niobium compounds, inorganic chemistry, etc., can solve the problem of high price, save production cost, overcome high cost, easy to mass production and industrial scale. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

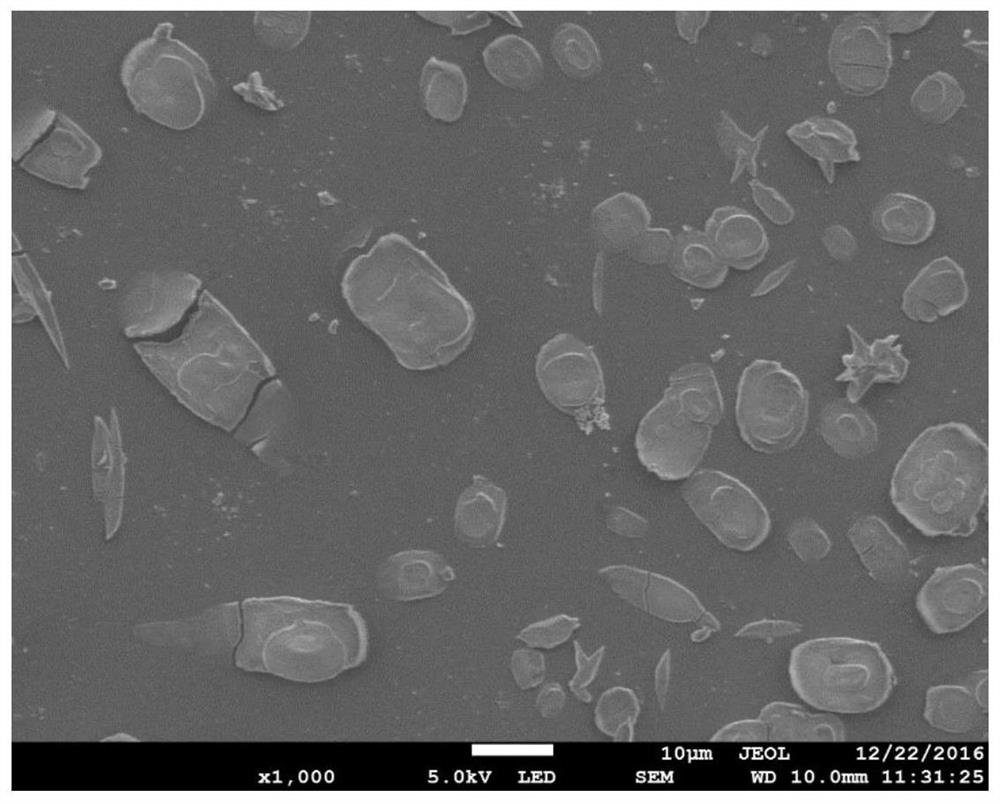

[0057] The KOH solid was dissolved in deionized water to prepare a KOH aqueous solution with a concentration of 8 mol / L, and cooled naturally to room temperature. Take 100mL of KOH aqueous solution and transfer it to a 500mL beaker, add 75g of Nb 2 o 5 , and the resulting suspension was magnetically stirred for 30 min. Dissolve 2.7 g of glycine (Gly) in a small amount of deionized water, add it into the suspension, and continue magnetic stirring for 30 min.

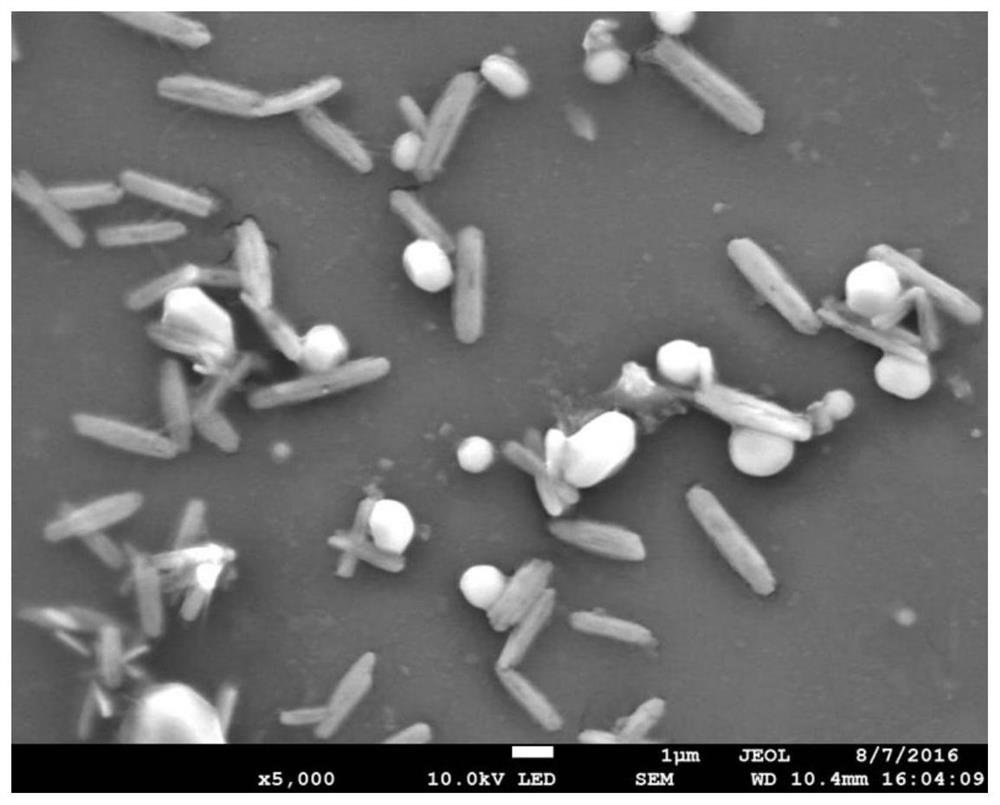

[0058] Then, the beaker was placed on a heating and stirring platform, and the reaction was stirred at 60° C. for 48 hours. After the reaction, let the reaction solution stand for a period of time, and the reaction solution is divided into a supernatant and a precipitate. Discard the supernatant, keep the precipitate, add an appropriate amount of deionized water for stirring and washing, and form a suspension. Transfer the suspension to a 100mL centrifuge tube and centrifuge at 500-100rpm for 10-20min. The obtained p...

Embodiment 2

[0065] The KOH solid was dissolved in deionized water to prepare a KOH aqueous solution with a concentration of 8 mol / L, and cooled naturally to room temperature. Take 100mL of KOH aqueous solution and transfer it to a 500mL beaker, add 75g of Nb 2 o 5 , and the resulting suspension was magnetically stirred for 30 min. Dissolve 2.7 g of serine (Ser) in a small amount of deionized water, add it into the suspension, and continue magnetic stirring for 30 min.

[0066] Then, the suspension was added into a 50 mL stainless steel reactor with a filling degree of about 80 vol%, and heated to 140° C. for 6 h. After the reaction was finished, the reaction solution was transferred to a 100mL beaker and left to stand for a period of time, and the reaction solution was divided into supernatant and precipitate. Discard the supernatant, keep the precipitate, add an appropriate amount of deionized water for stirring and washing, and form a suspension. Transfer the suspension to a 100mL c...

Embodiment 3

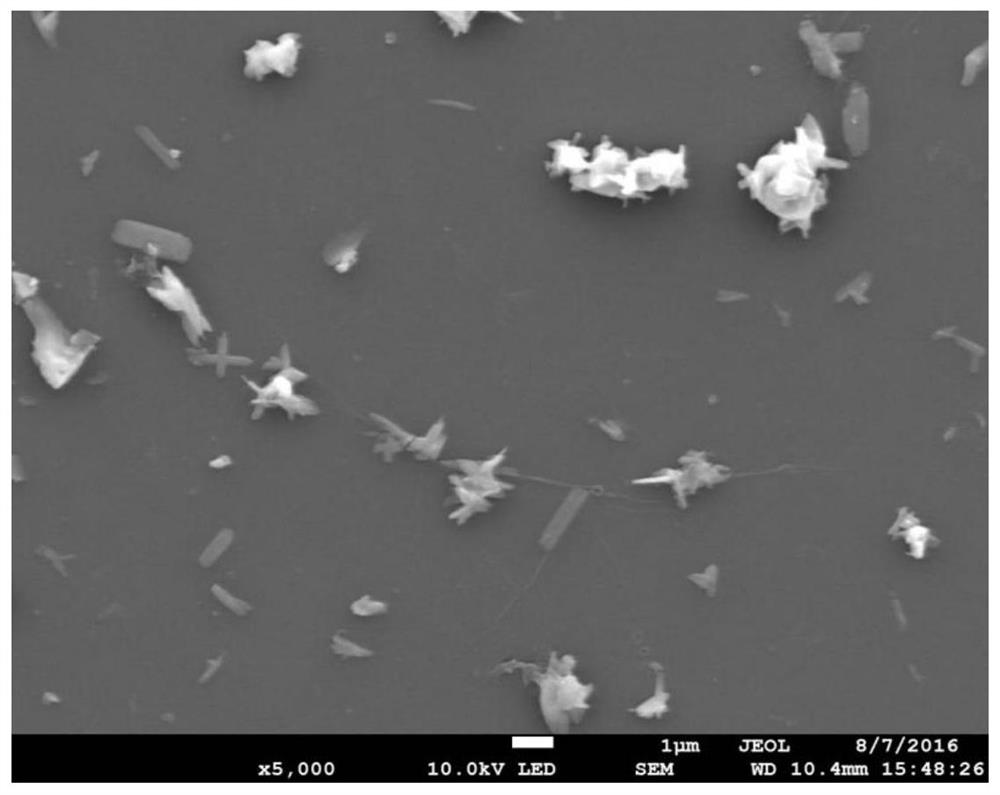

[0070] Dissolve KOH solid and NaOH solid in deionized water successively to prepare a mixed alkaline aqueous solution with a concentration of 4 mol / L, wherein the molar ratio of KOH to NaOH is 1:1, and cool naturally to room temperature. Take 100mL of mixed alkali aqueous solution and transfer it to a 500mL beaker, add 55g Nb 2 o 5 , and the resulting suspension was magnetically stirred for 30 min. Dissolve 3.3 g of proline (Pro) in a small amount of deionized water, add it into the suspension, and continue magnetic stirring for 30 min.

[0071] Then, the suspension was added into a 50 mL stainless steel reactor with a filling degree of about 70 vol%, and heated to 160° C. for 2 h. After the reaction was finished, the reaction solution was transferred to a 100mL beaker and left to stand for a period of time, and the reaction solution was divided into supernatant and precipitate. Discard the supernatant, keep the precipitate, add an appropriate amount of deionized water for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com