Ultraviolet light hydrogen peroxide catalytic oxidation device and process

A technology of catalytic oxidation and hydrogen peroxide, applied in the direction of light water/sewage treatment, oxidized water/sewage treatment, water pollutants, etc., can solve the problems of excessive sediment, lower treatment efficiency, large amount of sludge, etc., and achieve good COD degradation , Improve the effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

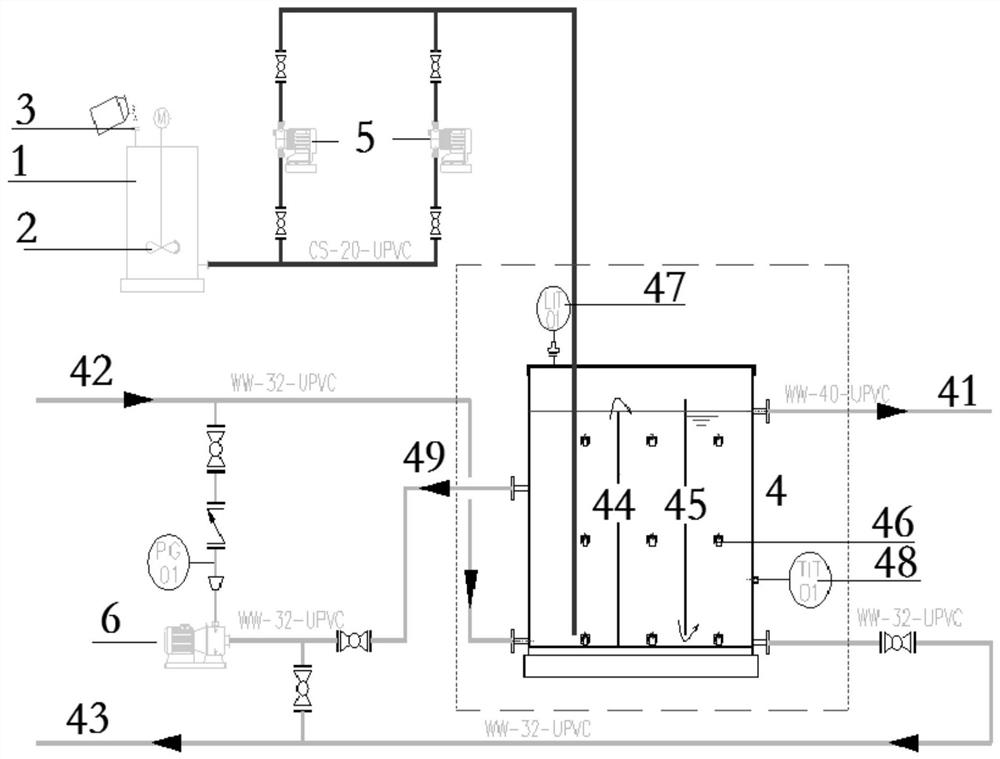

Method used

Image

Examples

specific Embodiment 1

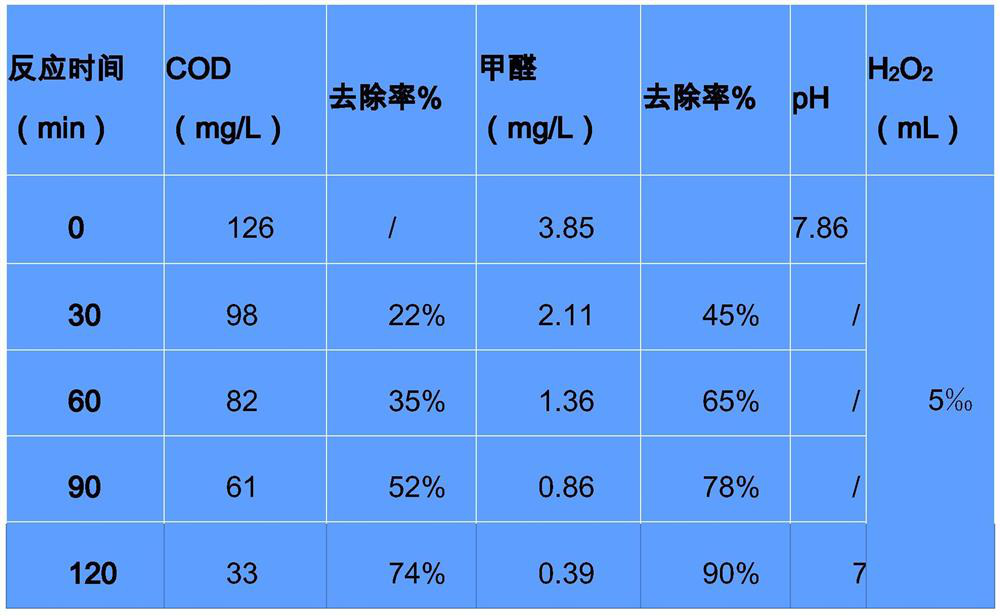

[0049] Specific embodiment 1 (ultraviolet lamp 32W, wavelength 185nm):

[0050]

[0051]

specific Embodiment 2

[0052] Specific embodiment 2 (ultraviolet lamp 32W, wavelength 205nm):

[0053]

specific Embodiment 3

[0054] Specific embodiment 3 (ultraviolet lamp 32W, wavelength 255nm):

[0055]

[0056] It can be seen that the wavelength between 185nm-255nm has the highest effect. In fact, according to the energy equation, ultraviolet light with shorter wavelength has stronger excitation energy, which can more effectively excite molecular bonds to dissociate and release free radicals; therefore, in pollutants In the field of processing, low-pressure ultraviolet light UV-C (253.7nm) is widely used; while UV-V with shorter wavelength has stronger energy, but its penetrating power is poor, and it can only be transmitted in a vacuum, so it cannot be widely used.

[0057] When the wavelength of the ultraviolet lamp is between 185nm and 255nm, it can achieve an optimal coordination effect between the energy density and the penetrating power, which is conducive to generating more hydroxyl radicals in the ultraviolet oxidation reactor, which can play a very important role. Good effect on degra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com