SBS modified asphalt regenerant and preparation method thereof

A technology of modified asphalt and regeneration agent, which is applied in the direction of building components, building insulation materials, construction, etc., can solve the problems of increased use cost and low reaction efficiency, and achieve the effect of facilitating recovery, uniform crystals, and preventing raw material agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

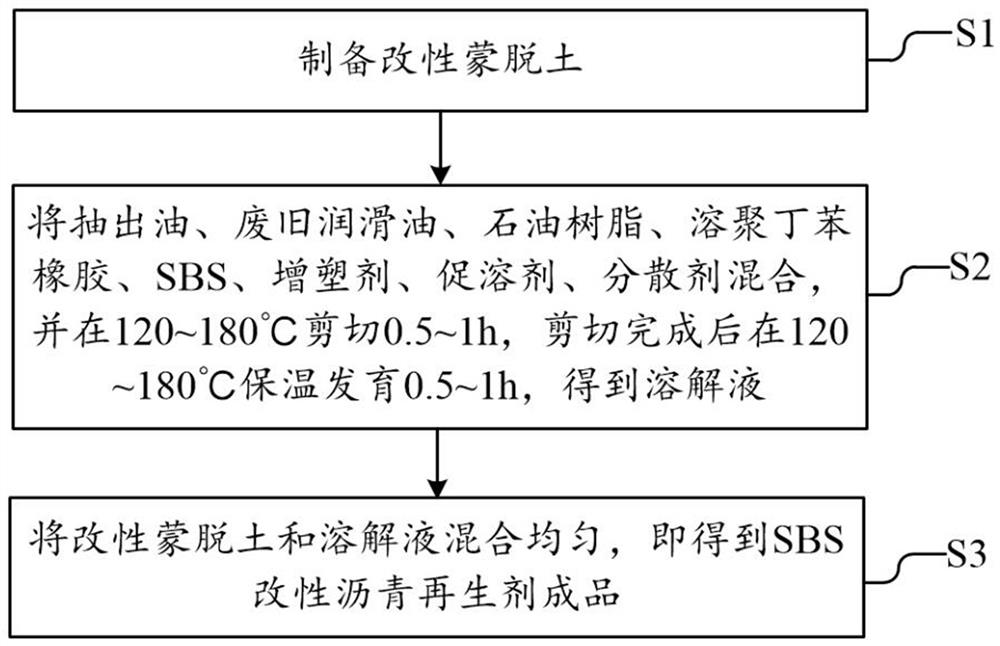

[0065] Correspondingly, refer to figure 1 , the present invention also discloses a preparation method of the above-mentioned SBS modified asphalt regenerant, which specifically includes the following steps:

[0066] S1: preparing modified montmorillonite;

[0067] S2: Mix the extracted oil, waste lubricating oil, petroleum resin, solution-polymerized styrene-butadiene rubber, SBS, plasticizer, solubilizer, and dispersant, and shear at 120-180°C for 0.5-1h. ~180°C incubation for 0.5~1h to obtain the solution;

[0068] Specifically, various raw materials are mixed and sheared for 30-50 minutes at a rotational speed of 4000-6000 rpm. During the shearing process, the temperature is maintained at 150-160 ° C. After the shearing is completed, it is incubated for 40-60 minutes to obtain a solution.

[0069] Preferably, when nano-titanium dioxide is contained in the formula of the present invention, nano-titanium dioxide is mixed with various raw materials in this step.

[0070] S3...

Embodiment 1

[0074] The present embodiment provides a kind of SBS modified asphalt regeneration agent, and its formula is as follows:

[0075] 80 parts of extraction oil, 10 parts of waste lubricating oil, 15 parts of petroleum resin, 3 parts of solution polystyrene butadiene rubber, 5 parts of SBS, 5 parts of naphthenic oil, 3 parts of silane coupling agent, dodecyl dihydroxyethyl betaine 2 parts, 0.5 parts of polypropylene wax, 2 parts of modified montmorillonite, and 1 part of stabilizer; the stabilizer is formed by mixing calcium carbonate and barium sulfate with a mass ratio of 3:5.

[0076] Its preparation method is:

[0077] (1) Preparation of modified montmorillonite;

[0078] Mix nano-montmorillonite and 15% dilute sulfuric acid at a ratio of 1:8, stir at 60°C for 50min, cool the mixture to room temperature, and refrigerate at -25°C for 5h. The mixture was taken out, boiled and dried under 3 standard atmospheric pressure, and the dodecyldimethylbenzyl ammonium bromide solution w...

Embodiment 2

[0082] The present embodiment provides a kind of SBS modified asphalt regeneration agent, and its formula is as follows:

[0083] 80 parts of extracted oil, 10 parts of waste lubricating oil, 15 parts of petroleum resin, 3 parts of solution polystyrene butadiene rubber, 5 parts of SBS, 5 parts of naphthenic oil, 4 parts of nano-titanium dioxide, 2 parts of dodecyl dihydroxyethyl betaine part, 0.5 part of polypropylene wax, 2 parts of modified montmorillonite, and 1 part of stabilizer; the stabilizer is mixed with calcium carbonate and barium sulfate with a mass ratio of 3:5.

[0084] Its preparation method is:

[0085] (1) Preparation of modified montmorillonite;

[0086] Same as embodiment 1;

[0087] (2) Mix the extracted oil, waste lubricating oil, petroleum resin, solution polystyrene butadiene rubber, SBS, naphthenic oil, nano-titanium dioxide, dodecyl dihydroxyethyl betaine, and polypropylene wax at a speed of 4000rpm, Cut at a temperature of 170°C for 50 minutes, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com