Efficient and clean leaching method for cathode material of failed lithium ion battery

A technology for lithium ion batteries and cathode materials, which is applied in the field of valuable metal recovery of cathode materials of failed lithium ion batteries, can solve the problems of poor operating environment, long leaching time, production interruption, etc., and achieves short leaching time, high leaching rate, and operation Continuous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The high-efficiency leaching method for the positive electrode material of the dead power lithium-ion battery in this embodiment includes the following steps:

[0033] (1) Prepare the raw materials. At a temperature of 25°C, mix the positive electrode material powder of the spent lithium iron phosphate battery with sulfuric acid (concentration: 1.5mol / L) at a liquid-solid ratio of 10mL / g, stir and mix for 10 minutes, and then mix the slurry Uniform;

[0034] (2) Pump the slurry into the circulation pipeline, slowly add hydrogen peroxide (6% by volume) with a theoretical molar mass of 1.2 times, the leaching temperature is 50°C, the reaction pressure is 0.1MPa, and the fluid flow rate is 2m / s;

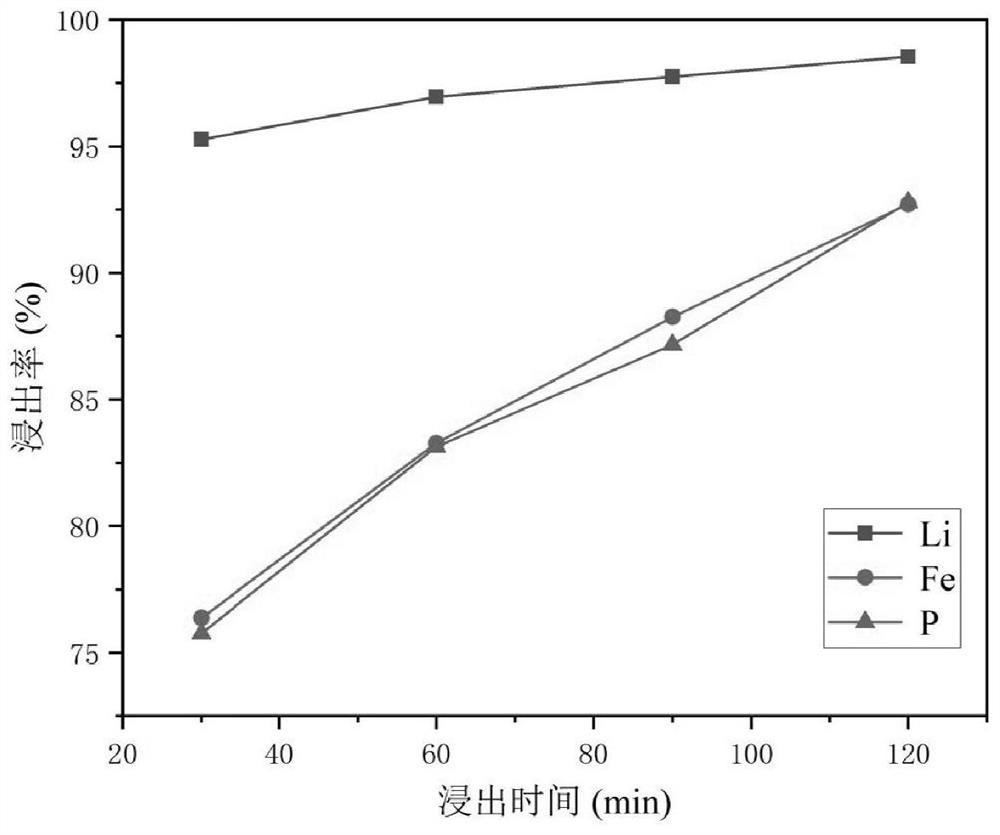

[0035] (3) The leaching is completed at 30 min, 60 min, 90 min, and 120 min, respectively, to obtain leaching solution and leaching residue containing lithium ions and iron ions.

[0036] After the above process, the leaching rate of the positive electrode material is as follows...

Embodiment 2

[0038] The high-efficiency leaching method for the positive electrode material of the dead power lithium-ion battery in this embodiment includes the following steps:

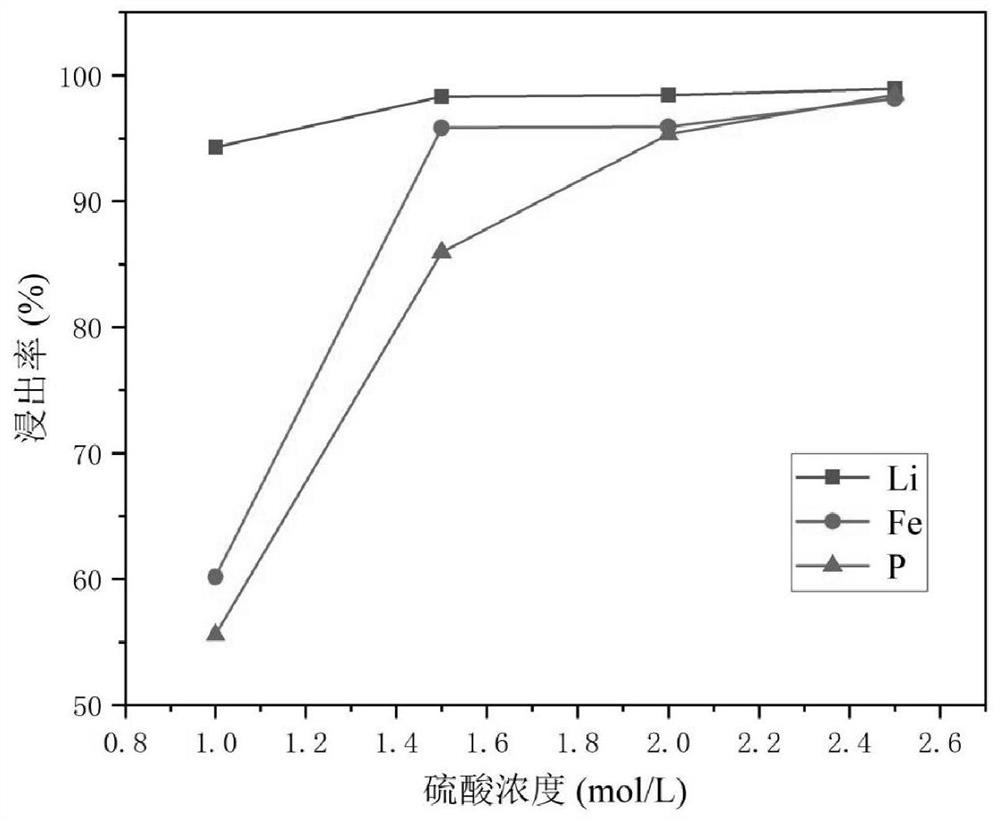

[0039] (1) Prepare the raw materials. At a temperature of 25°C, mix the positive electrode material powder of the invalid lithium iron phosphate battery with sulfuric acid with a concentration of 1mol / L, 1.5mol / L, 2mol / L, and 2.5mol / L respectively, according to the liquid-solid ratio 10mL / g for slurry mixing, after stirring and mixing for 20min, the slurry is evenly mixed;

[0040] (2) Pump the slurry into the circulation pipeline, slowly add hydrogen peroxide (6% by volume) with a theoretical molar amount of 1.2 times, the leaching temperature is 50°C, the reaction pressure is 0.2MPa, and the fluid flow rate is 2m / s;

[0041] (3) Be 120min in leaching time, finish leaching, obtain containing lithium ion and iron ion leaching solution and leaching slag, experimental result is as follows figure 2 It can be seen...

Embodiment 3

[0043] The high-efficiency leaching method for lithium-ion battery positive electrode materials of disabled products whose grades are not up to standard in this embodiment includes the following steps:

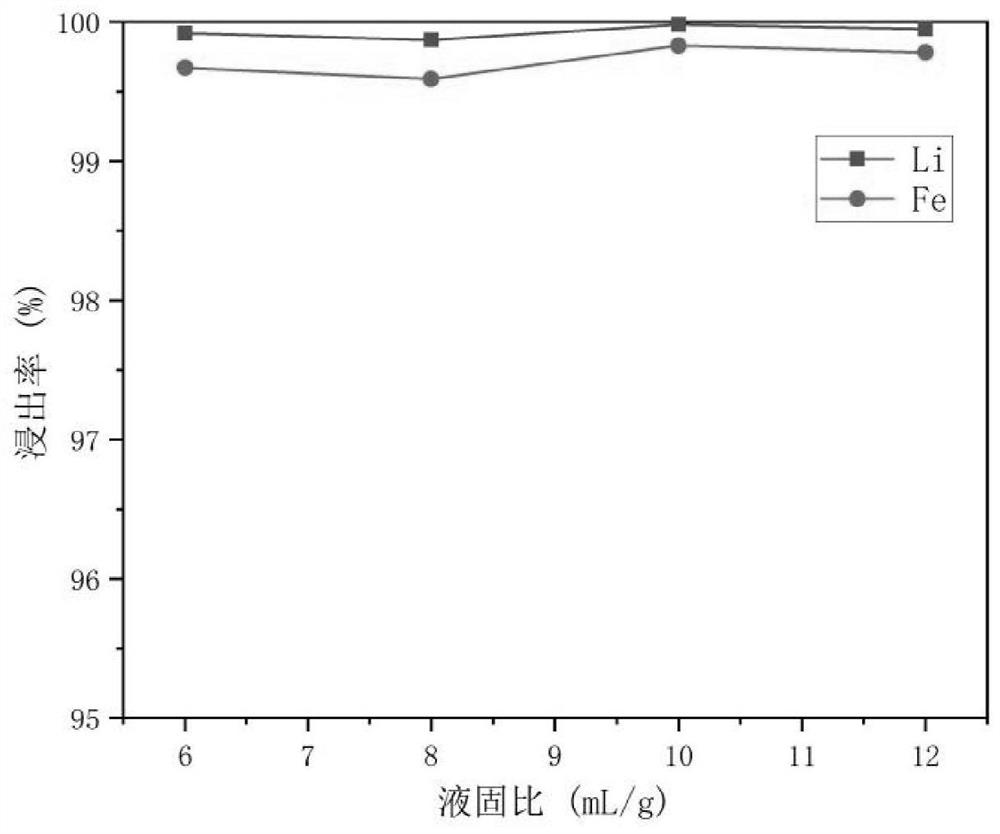

[0044] (1) Prepare the raw materials. Under the condition of temperature 25°C, the cathode material powder of lithium iron phosphate battery whose grade is not up to the standard is mixed with sulfuric acid with a concentration of 2mol / L according to the liquid-solid ratio of 6mL / g, 8mL / g, 10mL / g, 12mL / g for slurry mixing, after stirring and mixing for 10 minutes, the slurry is evenly mixed;

[0045] (2) Pump the slurry into the circulation pipeline, the leaching temperature is 40°C, the reaction pressure is 0.1MPa, and the fluid flow rate is 1m / s;

[0046] (3) Complete leaching in 15min, obtain leaching liquid and leaching slag, experimental result is as follows image 3 As shown, the change of liquid-solid ratio has little effect on the leaching rate of lithium and iron. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com