Melt-blown cloth with double-layer structure and preparation method of melt-blown cloth

A melt-blown cloth and structure technology, applied in non-woven fabrics, textiles and papermaking, filament forming processing and other directions, can solve problems such as inability to meet different types of fabrics, the same length and thickness of blown filaments, and raw materials containing more impurities, etc. To achieve the effect of reducing the stretching distance, improving the quality and improving the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

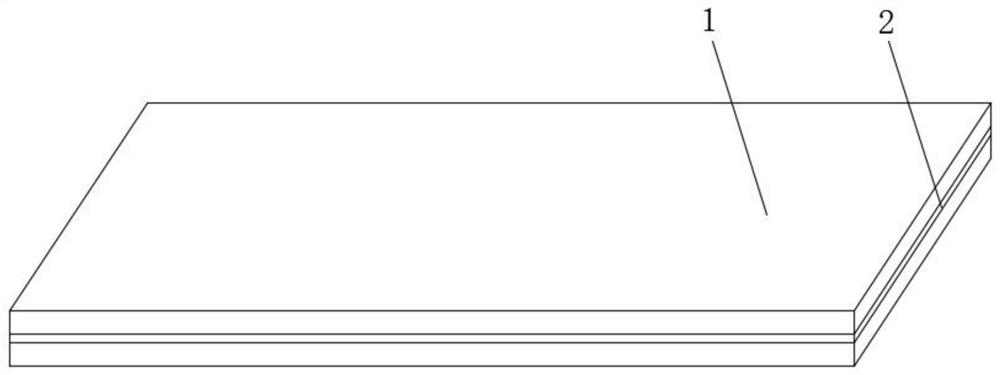

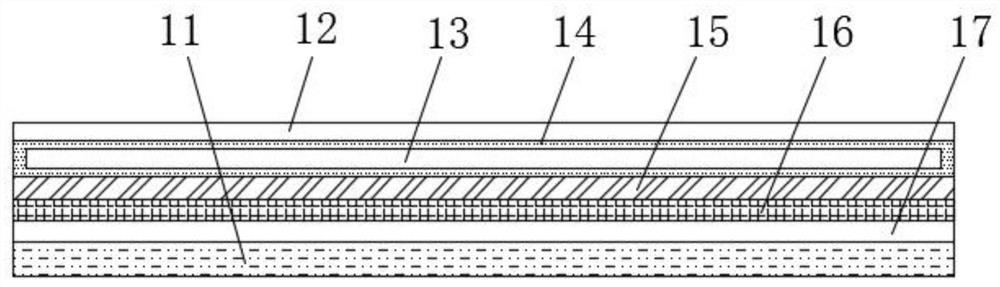

[0034] refer to Figure 1-2, a melt-blown cloth with a double-layer structure, including a single-layer cloth 1 and an adhesive layer 2, the number of the single-layer cloth 1 is two, and the two single-layer cloths 1 are bonded by the adhesive layer 2, Single layer cloth 1 comprises polypropylene base layer 11, and polypropylene base layer 11 is provided with bamboo charcoal fiber layer 17, is provided with nano antibacterial layer on bamboo charcoal fiber layer 17, is coated with polyester fiber layer 14 on the nano antibacterial layer, polyester fiber layer 14 is provided with an imported cotton fiber layer 12, the polyester fiber layer 14 is a double-layer hollow shape, the polyester fiber layer 14 is filled with activated carbon filter powder 13, and the nano-antibacterial layer includes a nano-silver layer 16 and a nano-copper oxide layer. Layer 15, nano-silver and nano-copper oxide layer 15 are all in powder form, and nano-copper oxide layer 15 is covered on nano-silver...

Embodiment 2

[0052] refer to Figure 1-2 , a melt-blown cloth with a double-layer structure, including a single-layer cloth 1 and an adhesive layer 2, the number of the single-layer cloth 1 is two, and the two single-layer cloths 1 are bonded by the adhesive layer 2, Single layer cloth 1 comprises polypropylene base layer 11, and polypropylene base layer 11 is provided with bamboo charcoal fiber layer 17, is provided with nano antibacterial layer on bamboo charcoal fiber layer 17, is coated with polyester fiber layer 14 on the nano antibacterial layer, polyester fiber layer 14 is provided with an imported cotton fiber layer 12, the polyester fiber layer 14 is a double-layer hollow shape, the polyester fiber layer 14 is filled with activated carbon filter powder 13, and the nano-antibacterial layer includes a nano-silver layer 16 and a nano-copper oxide layer. Layer 15, nano-silver and nano-copper oxide layer 15 are all in powder form, and nano-copper oxide layer 15 is covered on nano-silve...

Embodiment 3

[0070] refer to Figure 1-2 , a melt-blown cloth with a double-layer structure, including a single-layer cloth 1 and an adhesive layer 2, the number of the single-layer cloth 1 is two, and the two single-layer cloths 1 are bonded by the adhesive layer 2, Single layer cloth 1 comprises polypropylene base layer 11, and polypropylene base layer 11 is provided with bamboo charcoal fiber layer 17, is provided with nano antibacterial layer on bamboo charcoal fiber layer 17, is coated with polyester fiber layer 14 on the nano antibacterial layer, polyester fiber layer 14 is provided with an imported cotton fiber layer 12, the polyester fiber layer 14 is a double-layer hollow shape, the polyester fiber layer 14 is filled with activated carbon filter powder 13, and the nano-antibacterial layer includes a nano-silver layer 16 and a nano-copper oxide layer. Layer 15, nano-silver and nano-copper oxide layer 15 are all in powder form, and nano-copper oxide layer 15 is covered on nano-silve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com