Fracturing technology of foam fracturing fluid capable of independently generating heat and gas

A technology of foam fracturing fluid and self-generating heat, which is applied in the direction of drilling composition, production fluid, wellbore/well components, etc. It can solve the problem of reducing the conductivity of fracturing fractures, blocking flow channels, and increasing the viscosity of crude oil, etc. problems, to achieve the effect of reducing reservoir cold damage, increasing heat generation, and promoting viscous reduction of heavy oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

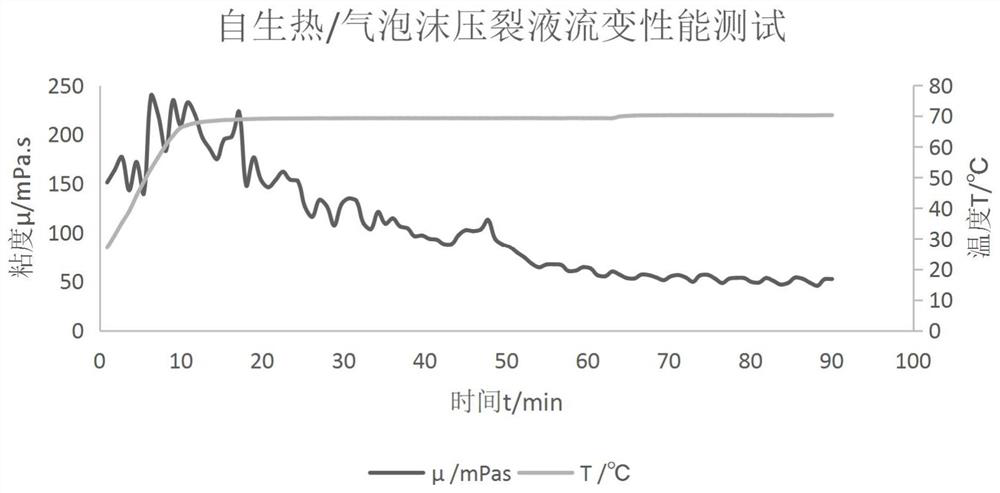

[0059] The above fracturing process was applied to a heavy oil reservoir in the Ordos Basin, and in this example, the thickening agent in the fracturing fluid was acid-resistant modified guar gum, the crosslinking agent was organic zirconium, and the heat generating agent A is sodium nitrite, heat generating agent B is ammonium chloride, heat generating catalyst is citric acid, breaking agent is sodium sulfite, gel breaking agent is ammonium persulfate, multifunctional additive is clay stabilizer potassium chloride. The rheological test results of the fracturing fluid are as follows: figure 1 shown, from figure 1 It can be seen that the fracturing fluid of the present invention has good rheological properties. The acid-resistant modified guar gum uses chloroacetic acid as the main etherification agent, the alkane epoxy compound is the secondary etherification agent, and ethanol or isopropanol is the dispersant, and the etherification reaction is carried out under alkaline con...

Embodiment 2

[0062] Different from Example 1, the heat generating catalyst in this example is sulfamic acid. By changing the type of heat-generating catalyst, the rate of heat-generating reaction and the breaking time of fracturing fluid are controlled.

[0063] In this embodiment, a total of 125m of clean fracturing fluid with self-generating heat and gas was pumped in 3 , 20 / 40 mesh quartz sand 35m 3 , the average sand-liquid ratio is 27.4%, the highest sand ratio is 30%, flowback after shutting down the well for 6 hours after fracturing, the flowback liquid is clean and free of residue, the flowback rate is 97.3%, the viscosity of the flowback liquid is 2.67mPa.s, and the daily output after fracturing Oil output of 8.7t / d was 4.14 times higher than that of 2.1t / d before production.

[0064] It should be noted that the use of other self-generated heat and gas-generating clean fracturing fluids disclosed in the prior art can also effectively reduce the problem of cold damage to reservoi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com