Flexible circuit board structure with aluminum foil replacing polymer flexible film and preparation process

A flexible circuit board and flexible film technology, applied in the direction of circuit substrate materials, printed circuit manufacturing, printed circuit, etc., can solve the problems of unsatisfactory, high cost of PI film, poor flexibility of PI film, etc., to improve high temperature resistance and circuit load The ability, structure and production process are simple, and the effect of reducing production and use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

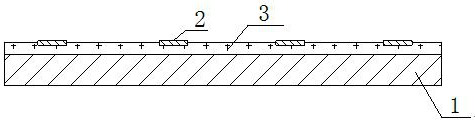

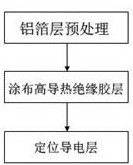

[0027] Such as figure 2 Shown, a kind of aluminum foil replaces the preparation technology of the flexible circuit board structure of polymer flexible film, comprises the following steps:

[0028] S1, the pretreatment of the aluminum foil layer, first spray and clean the surface of the aluminum foil layer with a lye solution with a temperature of 30°C and a concentration of 3%, then clean the surface of the aluminum foil with a temperature of 0°C deionized water, and then use a temperature of 0°C to ℃, an inert airflow with a flow rate of 0.3m / s dries the surface of the aluminum foil, and turns the dried aluminum foil over so that the upper end surface is parallel to the horizontal plane. Finally, the aluminum foil is placed in an inert gas protection environment at a constant temperature of 20 ℃. At the same time, the aluminum foil is subjected to corona treatment for 5 seconds. After the corona treatment is completed, a constant DC current of 0.1A is applied to the aluminum...

Embodiment 2

[0037] Such as figure 2 Shown, a kind of aluminum foil replaces the preparation technology of the flexible circuit board structure of polymer flexible film, comprises the following steps:

[0038] S1, pretreatment of the aluminum foil layer, first spray and clean the surface of the aluminum foil layer with 10% lye at a temperature of 60°C, then clean the surface of the aluminum foil with deionized water at a temperature of 20°C, and then use a temperature of 10°C to clean the surface of the aluminum foil layer. ℃, the inert airflow with a flow rate of 1.1m / s dries the surface of the aluminum foil, and turns the dried aluminum foil over so that the upper end surface is parallel to the horizontal plane, and finally the aluminum foil is placed in an inert gas protection environment at a constant temperature of 40 ℃. At the same time, the aluminum foil is subjected to corona treatment for 20 seconds. After the corona treatment is completed, a constant DC current of 1.5A is applie...

Embodiment 3

[0047] Such as figure 2 Shown, a kind of aluminum foil replaces the preparation technology of the flexible circuit board structure of polymer flexible film, comprises the following steps:

[0048] S1, pretreatment of the aluminum foil layer, first spray and clean the surface of the aluminum foil layer with 8% lye at a temperature of 45°C, then clean the surface of the aluminum foil with deionized water at a temperature of 10°C, and then clean the surface of the aluminum foil at a temperature of 5°C ℃, an inert airflow with a flow rate of 0.8m / s dries the surface of the aluminum foil, and turns the dried aluminum foil over so that the upper end surface is parallel to the horizontal plane, and finally the aluminum foil is placed in an inert gas protection environment at a constant temperature of 30 ℃. At the same time, the aluminum foil is subjected to corona treatment for 15 seconds. After the corona treatment is completed, a constant DC current of 1.3A is applied to the alumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com