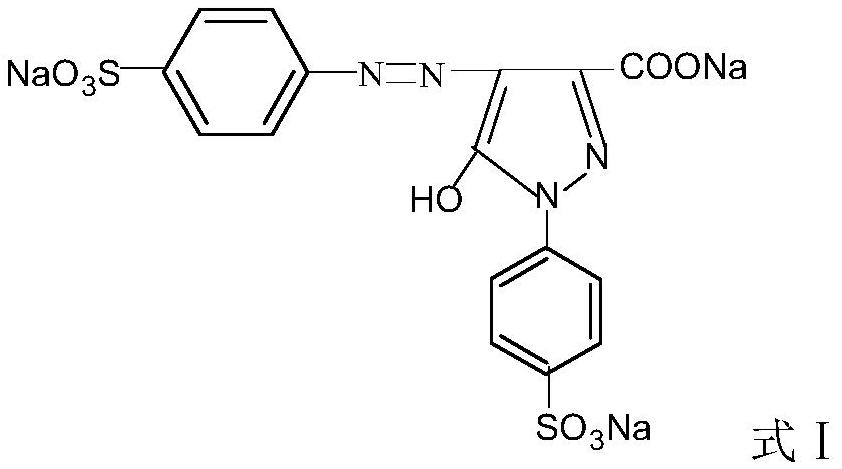

A kind of c.i. acid yellow 23 dye and its clean production process

A production process and cleaning technology, applied in the field of dyes, can solve the problems of limited scope of use, long synthesis routes, and product quality degradation, and achieve the effects of clean production process, stable quality, and improved yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

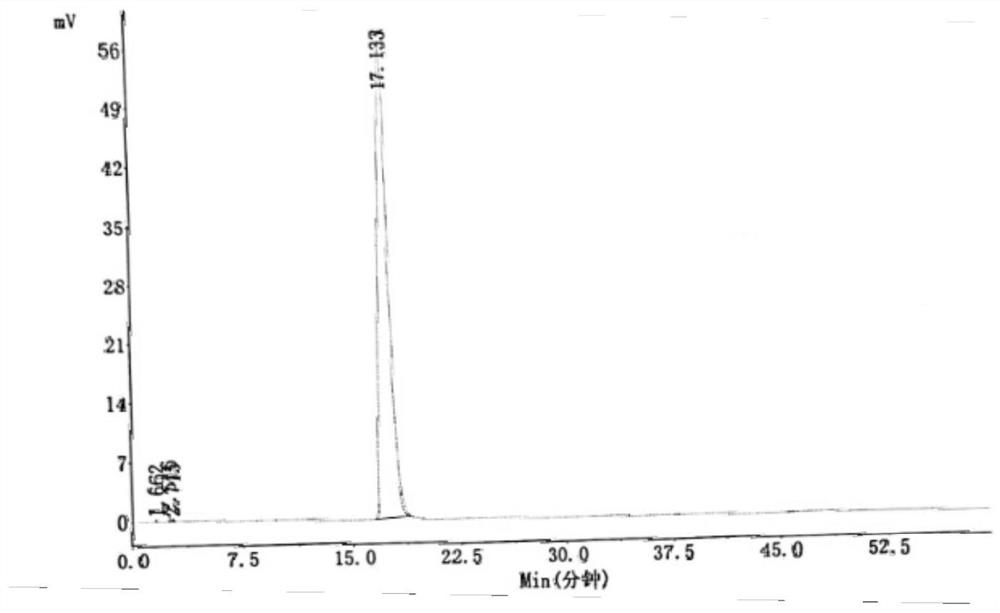

Image

Examples

Embodiment 1

[0079] Embodiment 1 of the present invention provides a kind of C.I. Acid Yellow 23 dyestuff, and its clean production process is specifically:

[0080] (1) react p-aminobenzenesulfonic acid in a medium of ice water, hydrochloric acid and sodium nitrite at 10°C for 1.5 hours to generate diazonium salt of p-aminobenzenesulfonic acid, and obtain solution 1;

[0081] (2) After adding sodium nitrite in the sulfamic acid elimination solution 1, add dimethyl 2-acetylsuccinate for a coupling reaction. At 15°C, adjust the pH to 4.3 for the reaction. After the reaction, adjust the pH to 7. Ring-closing reaction to obtain coupling components;

[0082] (3) p-aminobenzenesulfonic acid is reacted at 10°C for 1.5 hours in the medium of ice water, hydrochloric acid and sodium nitrite, and the diazonium salt of p-aminobenzenesulfonic acid should be generated, and solution 2 is obtained;

[0083] (4) After adding sulfamic acid to eliminate the sodium nitrite in the solution 2, add the couplin...

Embodiment 2

[0090] Embodiment 2 of the present invention provides a kind of C.I. Acid Yellow 23 dyestuff, and its clean production process is specifically:

[0091] (1) react p-aminobenzenesulfonic acid in a medium of ice water, hydrochloric acid and sodium nitrite at 15°C for 0.8h to generate diazonium salt of p-aminobenzenesulfonic acid, and obtain solution 1;

[0092] (2) After adding sodium nitrite in the sulfamic acid elimination solution 1, add dimethyl 2-acetylsuccinate for a coupling reaction. At 25°C, adjust the pH to 5 for the reaction. After the reaction, adjust the pH to 7.5. Ring-closing reaction to obtain coupling components;

[0093] (3) p-aminobenzenesulfonic acid is reacted at 15°C for 0.8h in the medium of ice water, hydrochloric acid and sodium nitrite, and the diazonium salt of p-aminobenzenesulfonic acid should be formed, and solution 2 is obtained;

[0094] (4) After adding sulfamic acid to eliminate the sodium nitrite in the solution 2, add the coupling component o...

Embodiment 3

[0101] Embodiment 3 of the present invention provides a kind of C.I. Acid Yellow 23 dyestuff, and its clean production process is specifically:

[0102] (1) react p-aminobenzenesulfonic acid in a medium of ice water, hydrochloric acid and sodium nitrite at 12°C for 1 hour to generate diazonium salt of p-aminobenzenesulfonic acid, and obtain solution 1;

[0103] (2) After adding sodium nitrite in the sulfamic acid elimination solution 1, add dimethyl 2-acetylsuccinate for a coupling reaction. At 20°C, adjust the pH to 4.7 for the reaction. After the reaction, adjust the pH to 7.1. Ring-closing reaction to obtain coupling components;

[0104] (3) p-aminobenzenesulfonic acid is reacted at 12°C for 1 hour in the medium of ice water, hydrochloric acid and sodium nitrite, and the diazonium salt of p-aminobenzenesulfonic acid should be generated to obtain solution 2;

[0105] (4) After adding sulfamic acid to eliminate the sodium nitrite in the solution 2, add the coupling component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com