In-vitro artificial reflex arc structure and construction method and application thereof

A construction method and technology of reflex arc, applied in the field of tissue engineering, can solve the problems of affecting the nerve activity of muscle groups around the reflex arc, unable to carry out long-term research, affecting the function of the reflex arc and electrophysiological response, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

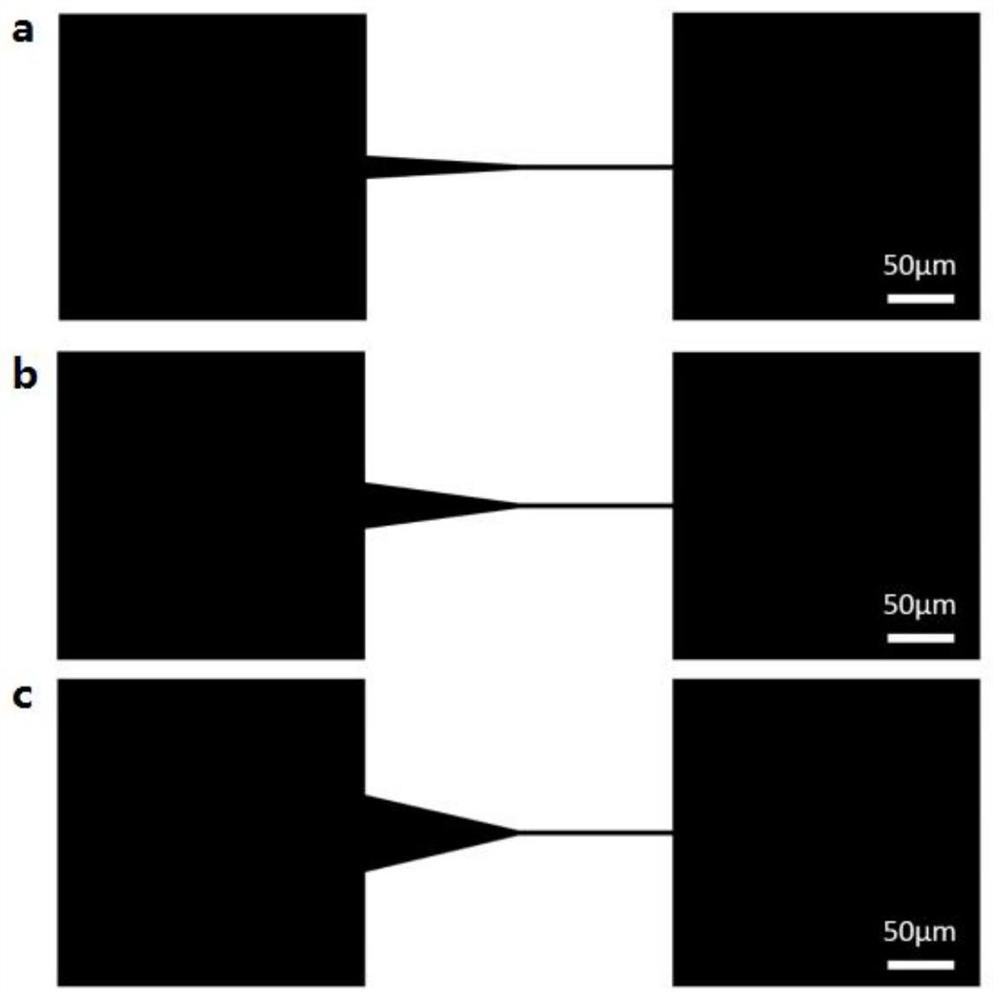

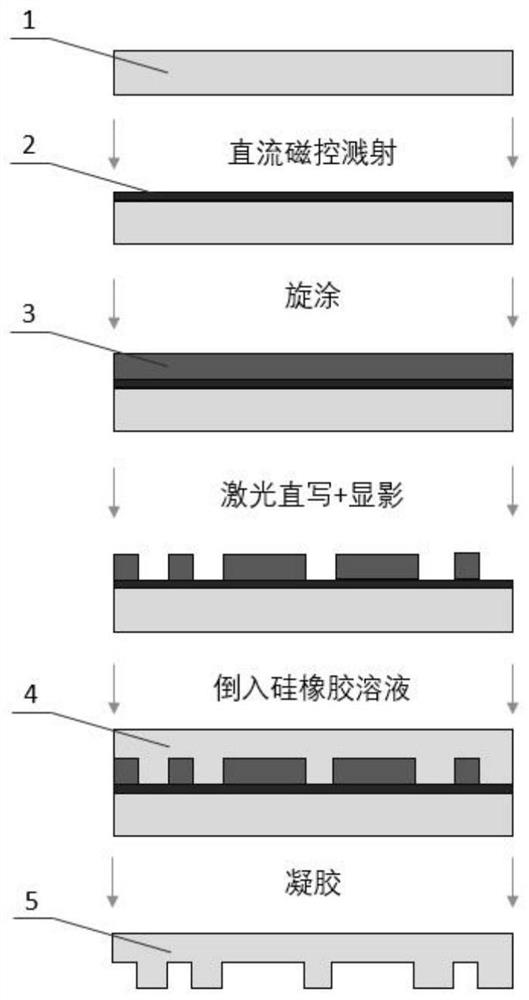

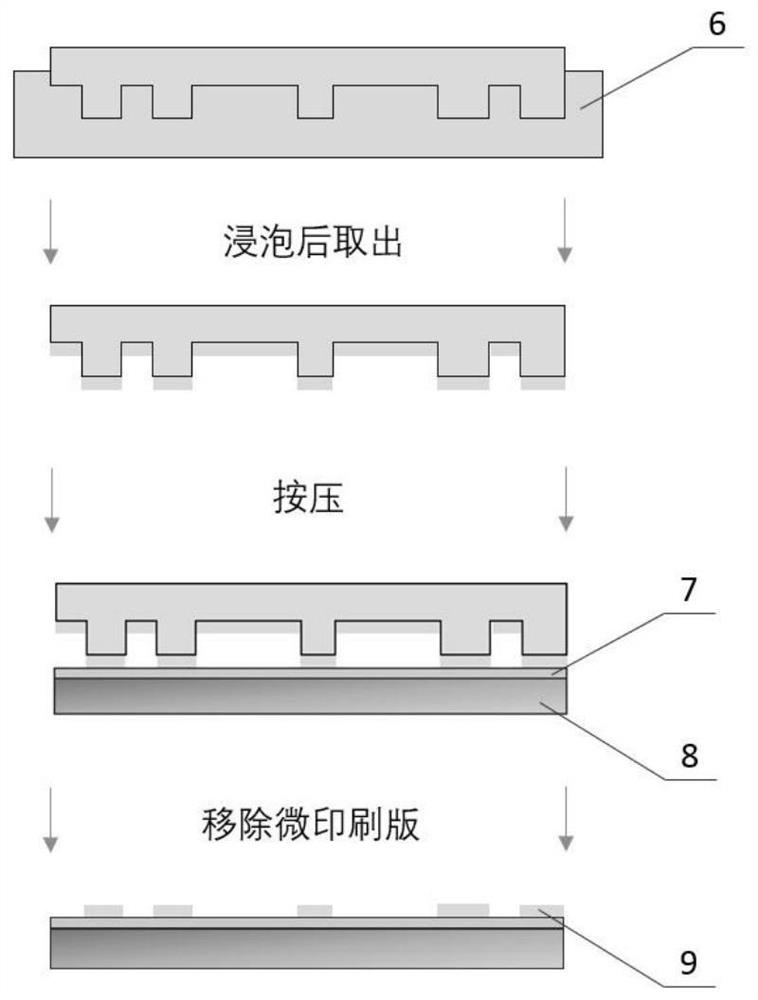

[0084] according to Figure 2-5 The flow chart shown constructs the artificial reflex arc structure in vitro, wherein, figure 2 Flowchart for the production of silicone rubber microprinting plate, image 3 Schematic diagram for microcontact printing, Figure 4 It is a schematic diagram of the structure of neurons cultured on the modified multi-electrode array culture dish, Figure 5 It is a flowchart of microcontact protein printing and neuron culture, in which, 1-soda glass substrate, 2-chromium nitride coating, 3-photoresist layer, 4-SYLGARD184, 5-silicone rubber microprinting plate, 6-adhesive Protein solution, 7- agarose coating, 8- petri dish for modified multi-electrode array, 9- microprotein pattern, 10- circular contact for multi-electrode array, 11- base for multi-electrode array, 12- dissected get of sensory neurons, 13 - sensory neurons with outstretched axons.

[0085] (1) Mask generator based on laser direct writing to directly prepare master

[0086] (1-1) ...

Embodiment 2

[0101] The in vitro artificial reflex arc-like structure was prepared according to the method of Example 1, the difference from Example 1 was that the maximum width of the thick section of the axon extension connection part in step (1-2) was 30 μm.

Embodiment 3

[0103] The in vitro artificial reflex arc-like structure was prepared according to the method of Example 1, the difference from Example 1 was that the maximum width of the thick section of the axon extension connection part in step (1-2) was 50 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com