Burdening method of electrode slurry and electrode slurry prepared by adopting burdening method

An electrode slurry and slurry technology, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve the problems of reduced shear force effect of stirring paddle, scrapped slurry, easy flow of slurry, etc., and achieve slurry dispersion. Uniformity, long cycle life and stable viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

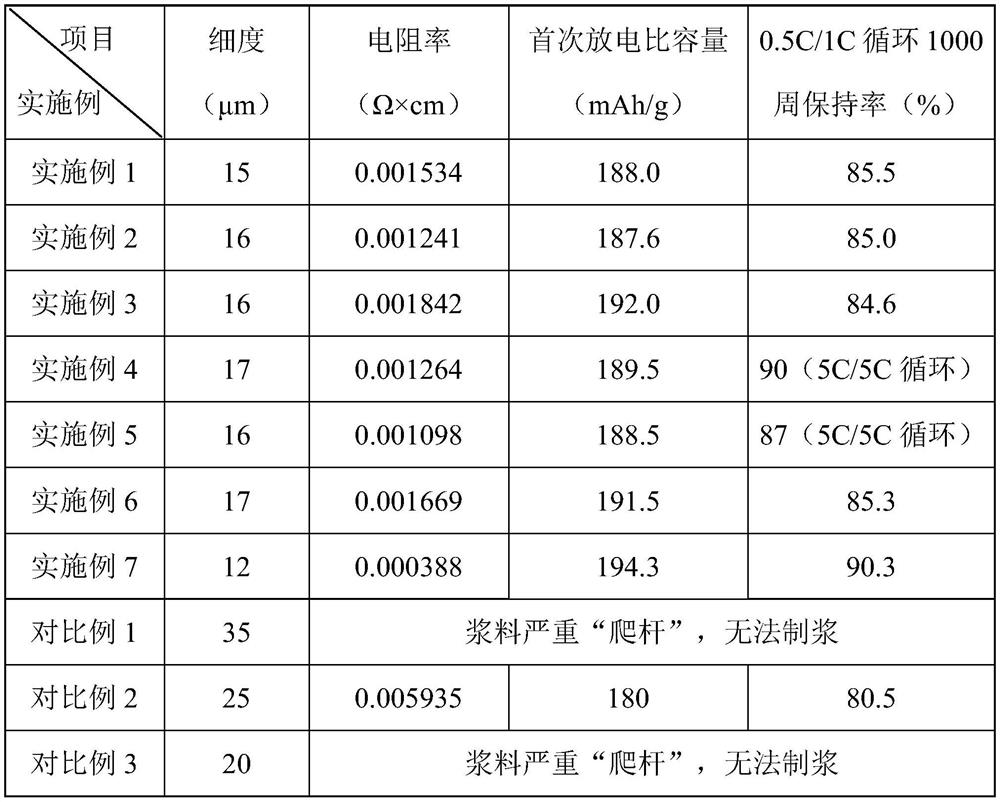

Embodiment 1

[0087] A batching process of lithium ion battery negative electrode slurry comprises the steps:

[0088] (1) According to the negative electrode slurry formula: negative electrode active material silicon oxide: conductive agent SP: thickener CMC: binder SBR mass ratio is 96.0:1.0:1.2:1.8, corresponding to solid powder silicon oxide, conductive The weight of agent SP and thickener CMC m 1 、m 2 and m 3 480g, 5g and 6g respectively. Determination of solid powder silicon oxide (D 小1 = 53mL / 100g and D 大1 =80mL / 100g), conductive agent SP (D 小2 = 339mL / 100g and D 大2 =480mL / 100g) and thickener CMC (D 小3 =77.5mL / 100g and D 大3 =110mL / 100g), the minimum oil absorption value and the maximum oil absorption value, the solvent adopted in the oil absorption value test process is linseed oil, and its density ρ is 0.935g / mL;

[0089] The determination of the oil absorption value in this example adopts the Gardner-Coleman method: put the solid powder in a container, add linseed oil at a...

Embodiment 2

[0098] A batching process of lithium-ion battery negative electrode slurry, the difference from Example 1 is:

[0099] The negative electrode slurry formula in step (1) is: negative electrode active material silicon oxide: conductive agent SP: thickener CMC: binder SBR = 93.8:3.0:1.2:2.0, corresponding to solid powder silicon oxide, conductive agent Weight of SP and thickener CMC m 1 、m 2 and m 3 469g, 15g and 6g respectively. Adopt the method identical with embodiment 1 to calculate and obtain step (3) " wetting " required deionized water weight g 1 =284.3g and step (4) "dilution" required deionized water weight g 2 =140.0g, all the other are identical with embodiment 1.

Embodiment 3

[0101] A batching process of lithium-ion battery negative electrode slurry, the difference from Example 1 is:

[0102] In step (1), the negative electrode slurry formula is: negative electrode active material natural graphite: conductive agent SP: thickener CMC: binder SBR=95.7:1.0:1.4:1.9, corresponding to solid powder natural graphite, conductive agent SP and Thickener CMC weight m 1 、m 2 and m 3 479g, 5g and 7g respectively. The minimum oil absorption value D of the natural graphite 小 =55.7mL / 100g, the maximum oil absorption value D 大 =80mL / 100g, calculate the weight of deionized water required for step (3) "wetting" g 1 =270.1g and step (4) "dilution" required deionized water weight g 2 =117.4g, all the other are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com