High-efficiency dissolving equipment for crude salt purification and using method

A high-efficiency, crude salt technology, applied in the direction of dissolution, chemical instruments and methods, mixers, etc., can solve the problems of sinking, affecting dissolution, small contact surface, etc., and achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

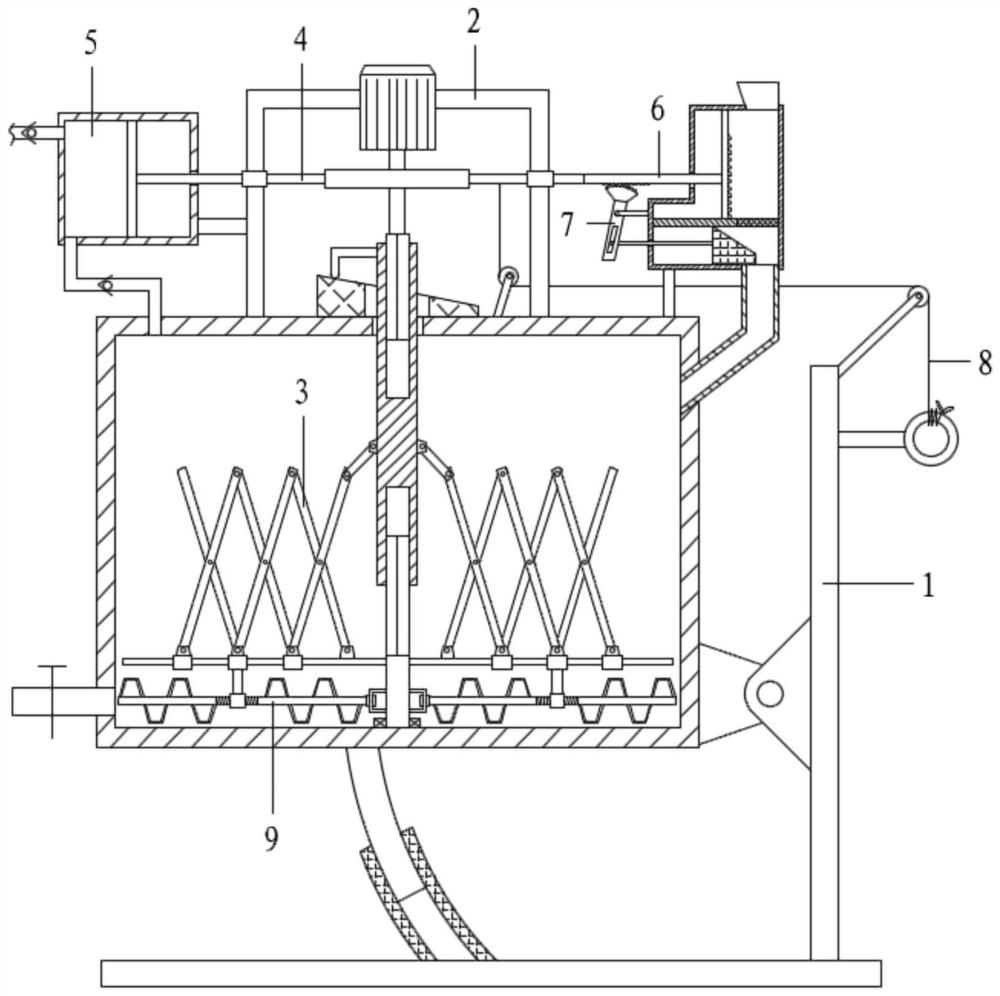

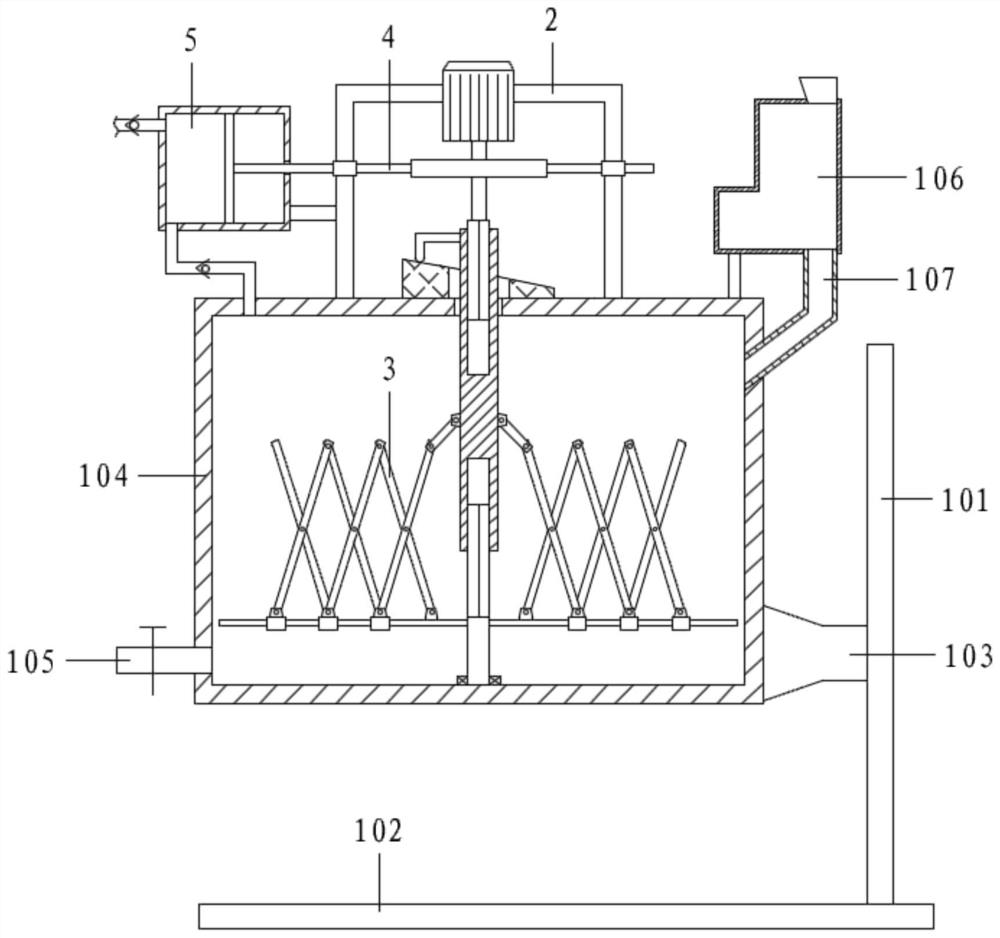

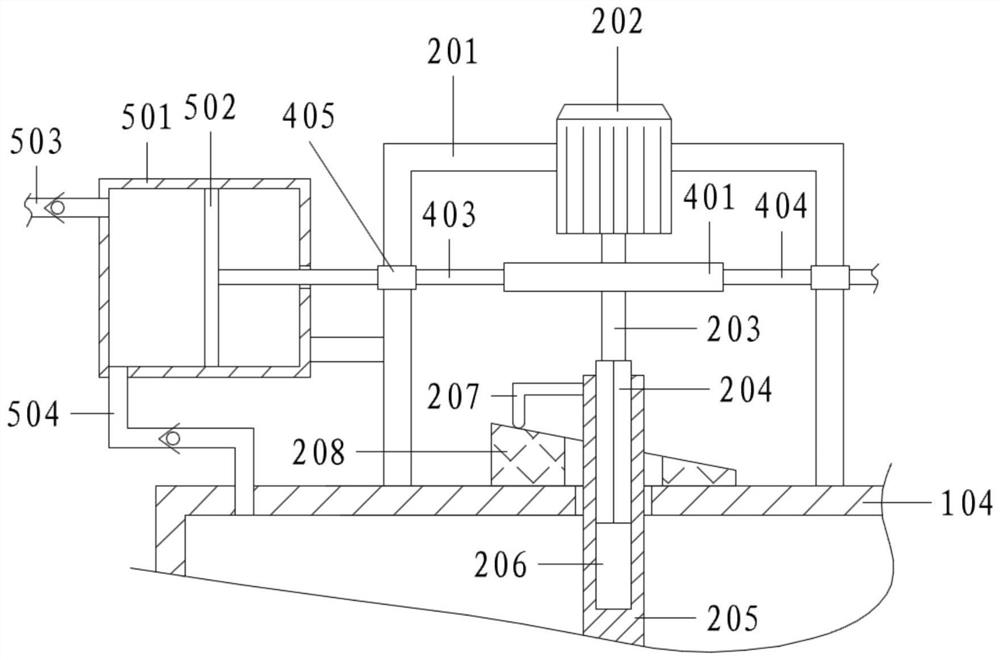

[0070] With reference to the accompanying drawings, a high-efficiency crude salt purification dissolving device includes a tank assembly 1, a drive assembly 2, a stirring assembly 3, a reciprocating assembly 4 and a liquid addition assembly 5;

[0071] The tank assembly 1 includes a side plate 101, a base 102, a connecting seat 103, a dissolving tank 104, a drain pipe 105, a coarse salt tank 106 and a feed pipe 107; the right end of the base 102 is fixedly connected with a side plate 101; Above 102, the left bottom is connected with a drain pipe 105, and a valve is housed on the drain pipe 105;

[0072] The right side of the dissolving tank 104 is connected with the side plate 101 through the connecting seat 103; the top of the dissolving tank 104 is provided with a driving assembly 2, and the dissolving tank 104 is provided with a stirring assembly 3, and the bottom end of the driving assembly 2 extends into the tank body assembly 1 and is connected with the Stirring componen...

Embodiment 2

[0075] With reference to the accompanying drawings, a high-efficiency crude salt purification dissolving device includes a tank assembly 1, a drive assembly 2, a stirring assembly 3, a reciprocating assembly 4 and a liquid addition assembly 5;

[0076] The tank assembly 1 includes a side plate 101, a base 102, a connecting seat 103, a dissolving tank 104, a drain pipe 105, a coarse salt tank 106 and a feed pipe 107; the right end of the base 102 is fixedly connected with a side plate 101; Above 102, the left bottom is connected with a drain pipe 105, and a valve is housed on the drain pipe 105;

[0077] The right side of the dissolving tank 104 is fixedly connected by the connecting seat 103 and the side plate 101; the top of the dissolving tank 104 is provided with a driving assembly 2, and the dissolving tank 104 is provided with a stirring assembly 3, and the bottom end of the driving assembly 2 extends into the tank body assembly 1 and Connect with stirring assembly 3;

...

Embodiment 3

[0096] On the basis of the above examples,

[0097] Coarse salt tank 106 is equipped with a partition 108, and the right section of the partition 108 is embedded with a filter screen 109; a crushing assembly 6 is arranged above the partition 108, and a drug feeding assembly 7 is arranged below; the crushing assembly 6 is connected with the reciprocating assembly 4, and the drug feeding Assembly 7 cooperates with crushing assembly 6 .

[0098] The crushing assembly 6 includes a rack 601, a pressing plate 602 and crushing teeth 603;

[0099] A pressing plate 602 is slidingly installed between the dividing plate 108 and the inner top of the coarse salt box 106, the left side of the pressing plate 602 is connected with a rack 601, and the left end of the rack 601 extends out of the coarse salt box 106 and is connected with the right moving rod 404; the right side of the pressing plate 602 A crushing tooth 603 is attached.

[0100] The drug dispensing assembly 7 includes a sector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com