Preparation of nano-crystalline cellulose aerogel material with high strength and high adsorption performance

A nanocellulose and aerogel technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of cumbersome and toxic operations, protect the environment, improve adsorption performance, The effect of the simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

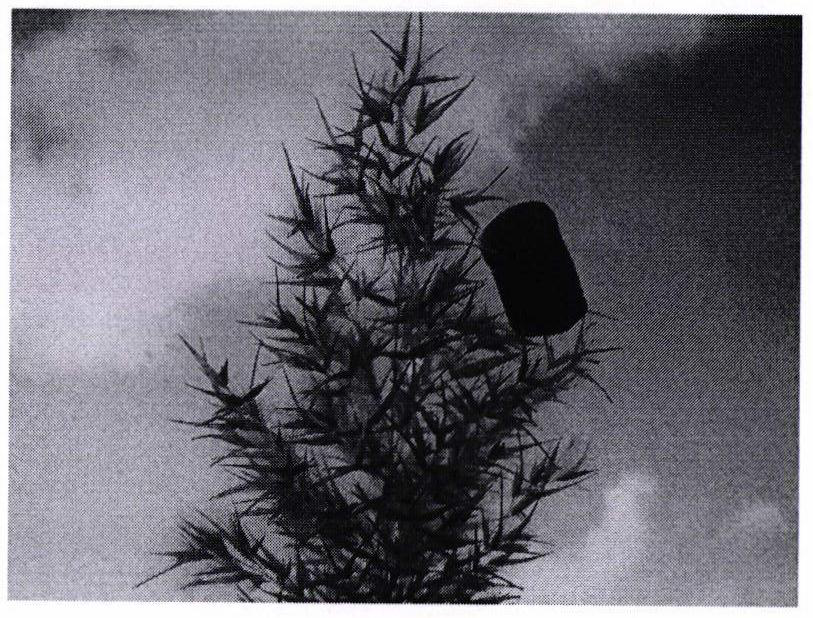

[0022] The nanocellulose hydrogel material was prepared by calcium ion cross-linking method, soaked in 3 mg / mL dopamine solution, and fully soaked for 12 hours. After being taken out, ammonia water and ethanol are added to make the dopamine grow on the nano-cellulose in situ to obtain a polydopamine-modified nano-cellulose hydrogel material. Soak the polydopamine-modified nanocellulose hydrogel material in a 0.1 mmol / L silver nitrate solution and react for 1 h. The hydrogel material was freeze-dried to obtain the airgel material (attached figure 1 ). Carry out intensity measurement, then use airgel material to adsorb methylene blue (200mg / L), and measure the adsorption amount after 6 hours. Then, catalytic degradation was carried out in a solution of sodium borohydride, wherein the concentration of sodium borohydride was 0.2mmol / L, and the irradiation power of near-infrared light was 2W. Finally, the adsorbent material is recycled.

[0023] The amount of dye adsorption was...

Embodiment 2

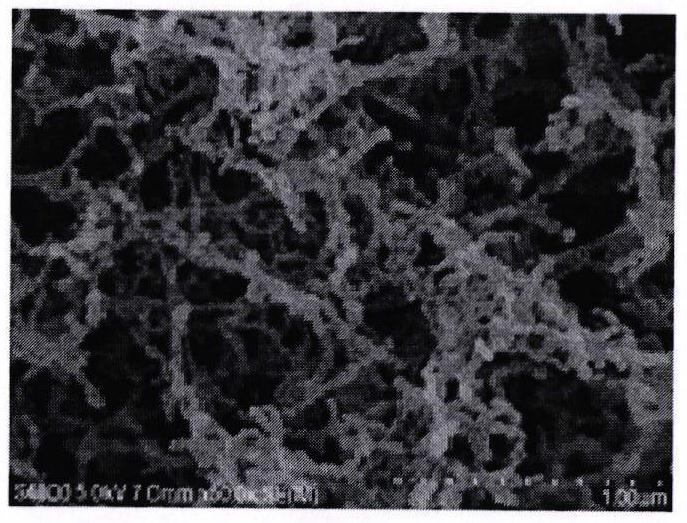

[0027] The nanocellulose hydrogel material was prepared by calcium ion cross-linking method, which was soaked in a solution of 4 mg / mL dopamine for 24 hours. After being taken out, ammonia water and ethanol are added to make the dopamine grow on the nano-cellulose in situ to obtain a polydopamine-modified nano-cellulose hydrogel material. Soak the polydopamine-modified nanocellulose hydrogel material in a 0.1 mmol / L silver nitrate solution and react for 1 h. The hydrogel material is freeze-dried to obtain an airgel material, and the SEM image of the airgel material is as follows figure 2 shown. Intensity measurement was carried out, and then the airgel material was used to adsorb methyl orange (200 mg / L), and the adsorption amount was measured after 6 hours. Then, catalytic degradation was carried out in a solution of sodium borohydride, wherein the concentration of sodium borohydride was 0.2mmol / L, and the irradiation power of near-infrared light was 4W. Finally, the adso...

Embodiment 3

[0032] The nanocellulose hydrogel material was prepared by calcium ion cross-linking method, soaked in a 3 mg / mL dopamine solution, and fully soaked for 48 hours. After being taken out, ammonia water and ethanol are added to make the dopamine grow on the nano-cellulose in situ to obtain a polydopamine-modified nano-cellulose hydrogel material. Soak the polydopamine-modified nanocellulose hydrogel material in a 0.1 mmol / L silver nitrate solution and react for 1 h. The hydrogel material is freeze-dried to obtain an airgel material. Carry out intensity measurement, then use airgel material to adsorb Congo red (200mg / L), and measure the adsorption amount after 6 hours. Then, catalytic degradation was carried out in a solution of sodium borohydride, wherein the concentration of sodium borohydride was 0.2mmol / L, and the irradiation power of near-infrared light was 6W. Finally, the adsorbent material is recycled.

[0033] The amount of dye adsorption was calculated according to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com