Continuous basalt fiber surface treating agent and preparation method thereof

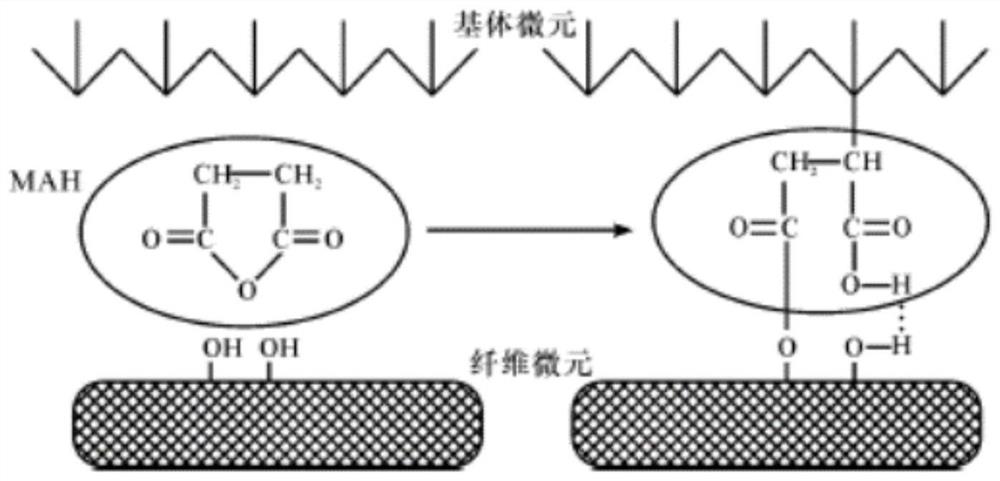

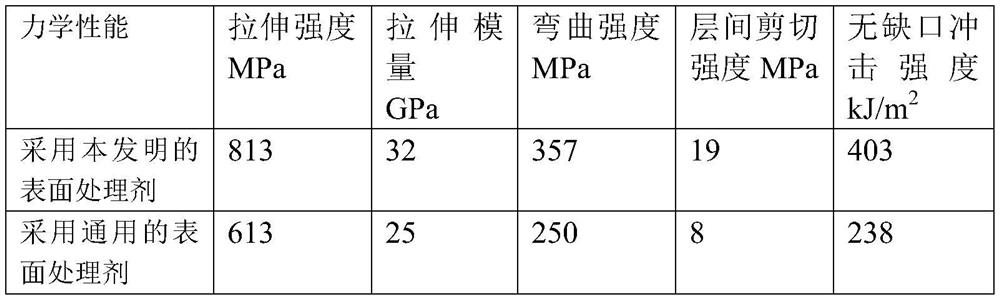

A technology of basalt fiber and surface treatment agent, which is applied in the field of preparation of surface treatment agent, can solve the problems of poor interfacial properties of basalt fiber, and achieve the effects of improving process performance, good wettability, and good reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1: Prepare surface treatment agent

[0028] In 100 parts by weight of deionized water, add 5 parts of film-forming agent, 0.1 part of lubricant, 0.2 part of coupling agent and 0.1 part of antistatic agent, and stir evenly at a temperature of 20° C. to prepare a surface treatment agent.

[0029] The film-forming agent is polypropylene grafted maleic anhydride, the graft ratio is 1%, and contains 5% Span-80.

[0030] The lubricant is the reaction product of nonanoic acid and tetraethylenepentamine.

[0031] The coupling agent is γ-aminopropyltriethoxysilane (KH550).

[0032] The antistatic agent is tributylmethylammonium bistrifluoromethylsulfonimide salt.

[0033] Step 2: Impregnating Fibers

[0034] Immerse the continuous basalt fiber under the action of the traction device into the storage tank where the surface treatment agent prepared in the first step is placed, the traction speed is 2m / min, and then dry at a temperature of 80°C for 1h to obtain the surface-...

Embodiment 2

[0042] Step 1: Prepare surface treatment agent

[0043] In 100 parts by weight of deionized water, add 10 parts of film-forming agent, 0.5 part of lubricant, 1.0 part of coupling agent and 0.2 part of antistatic agent, and stir evenly at a temperature of 20°C.

[0044] The film-forming agent is polypropylene grafted maleic anhydride, its graft ratio is 2%, and contains 6% emulsifier sodium lauryl sulfate.

[0045] The lubricant is long-chain alkyl modified silicone oil.

[0046] The coupling agent is γ-aminopropyl triethoxysilane (KH550), γ-glycidyl etheroxypropyl trimethoxysilane (KH560) and γ-methacryloxypropyl trimethoxy A combined solution of silane (KH570).

[0047] The antistatic agent is 1-butyl-3-methylimidazolium chloride.

[0048] Step 2: Impregnating Fibers

[0049]Immerse the continuous basalt fiber on the sizing roller with the surface treatment agent prepared in the first step under the action of the traction device, the traction speed is 5m / min, and then dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com