Drag reducer with high stability as well as preparation method and application thereof

A drag reducer and surfactant technology, applied in the field of drag reducer and its preparation, can solve the problems of unfavorable long-term storage and long-distance transportation, low selectivity of slippery aquatic products, inconvenient on-site preparation and use, etc., to meet the requirements of Long-term storage and long-distance transportation, improved sand-carrying capacity and salt tolerance, and convenient on-site use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

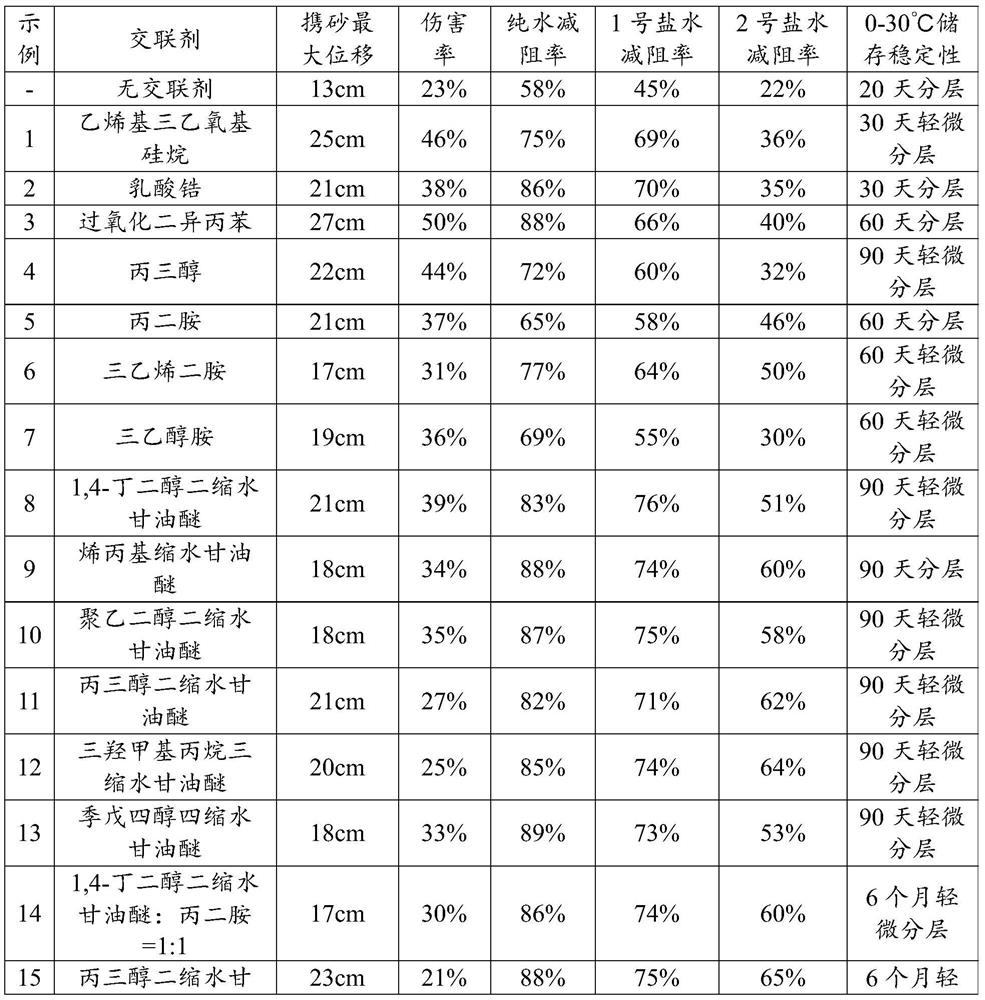

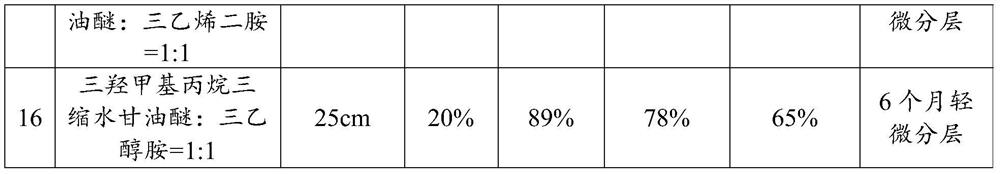

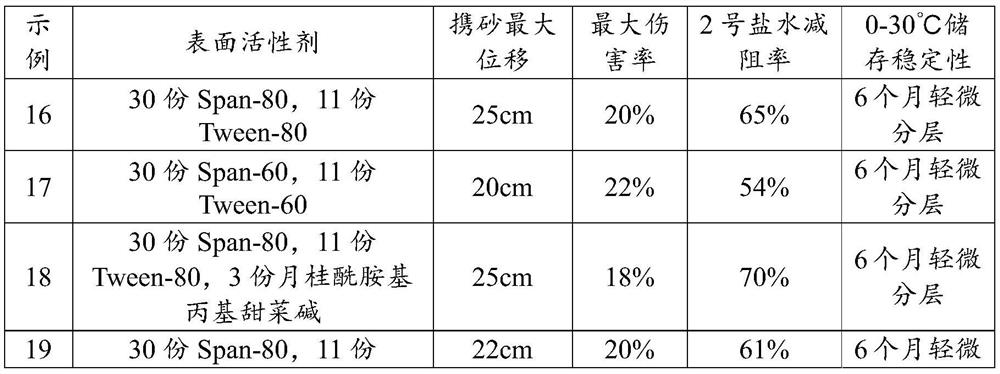

Examples

Embodiment 1

[0031] This embodiment provides a drag reducer suitable for preparing oilfield slick water fracturing fluid, which is prepared from the following raw materials in parts by weight:

[0032] 40 parts of deionized water, 45 parts of acrylamide monomer, 2 parts of crosslinking agent, 1 part of fatty alcohol polyoxyethylene ether, 1 part of polyisobutylene polysuccinimide, 40 parts of white oil, 30 parts of sorbitan Fatty acid ester Span-80, 11 parts of polyoxyethylene sorbitan fatty acid ester Tween-80, 0.8 parts of sodium edetate, 0.655 parts of initiator, the initiator is composed of sodium bisulfite and ammonium sulfate, The mass ratio of sodium bisulfate and ammonium sulfate is 1:1.

[0033] The above raw material components are prepared by the following method to obtain the drag reducer:

[0034] Step 1: Preparation of aqueous phase solution

[0035]Add 400kg of deionized water into a clean stainless steel reactor, start stirring, control the stirring speed to 70-80r / min, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com