Low-temperature and rapid iron ore oxidized pellet preparation method and system

An oxidation pelletizing and rapid technology, applied in the low temperature and rapid iron ore oxidation pellet preparation system, the oxidation pellet preparation, the low temperature and rapid iron ore oxidation pellet preparation field, can solve the limitation of iron ore pellet technology industry Promote, increase the risk of material ring formation, affect production stability, etc., to achieve the effect of improving ventilation and heat uniformity, preventing the occurrence of ring formation, and high compressive and falling strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0069] According to the first embodiment of the present invention, a kind of low temperature and rapid iron ore oxidation pellet preparation method is provided:

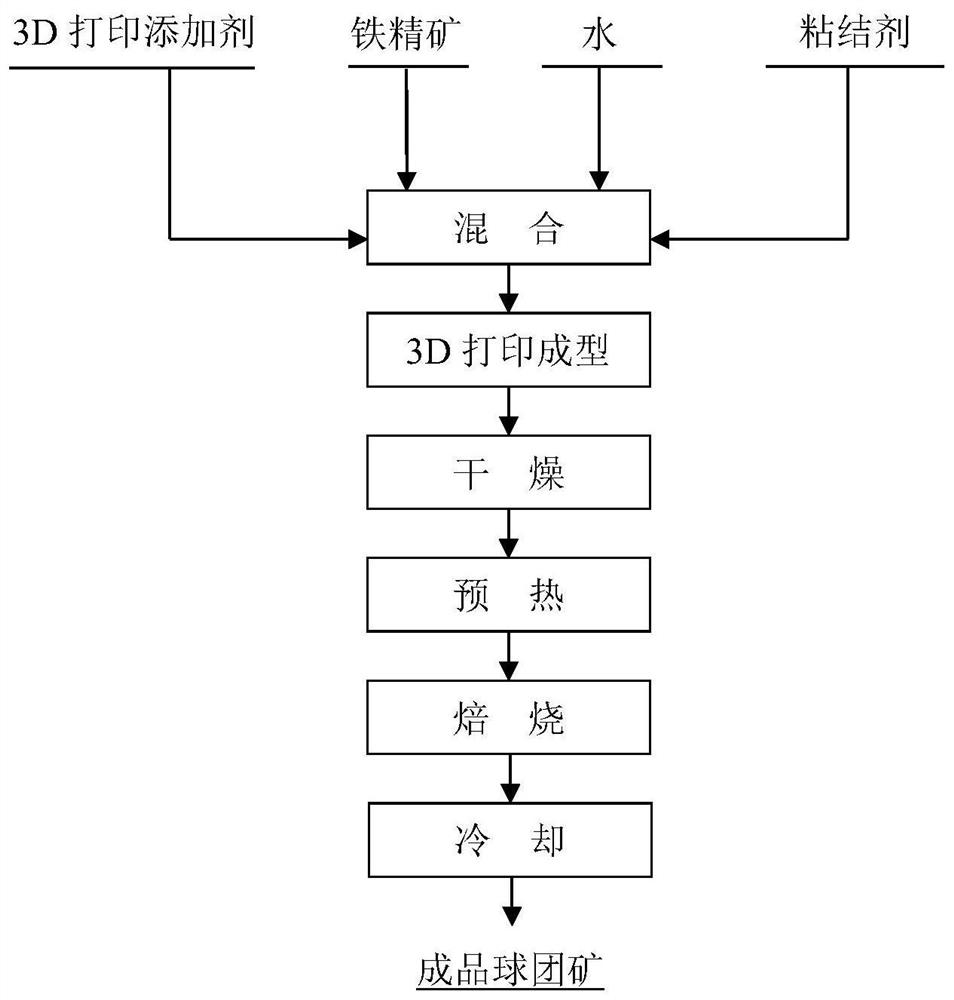

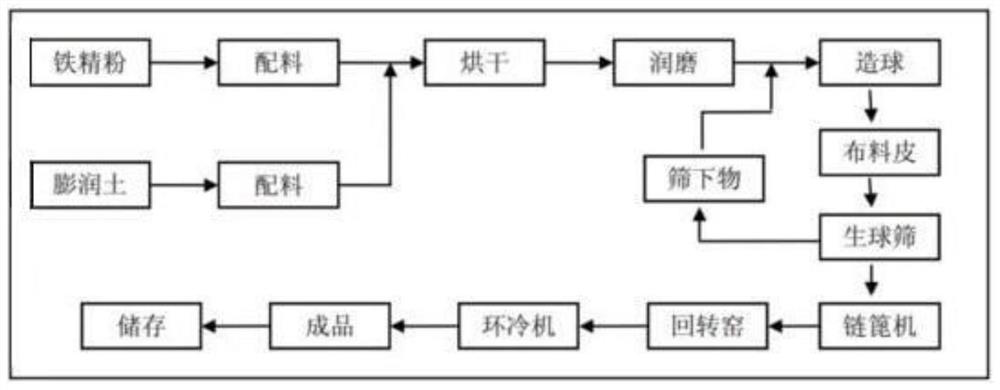

[0070] A low-temperature and fast method for preparing iron ore oxidized pellets, the method comprising the following steps: 1) making a 3D printing mixture: uniformly mixing raw materials to obtain a 3D printing mixture, the raw materials including: iron concentrate, bonding agent, titanium dioxide, vanadium pentoxide, fiber; 2) making pellets: using 3D printing technology to make 3D printing mixture into green pellets; 3) prefabrication treatment: prefabricating and drying the green pellets to obtain dry Green pellets; 4) Oxidation and roasting treatment: Carry out oxidation and roasting treatment on the dried green pellets to obtain finished pellets.

[0071] As preferably, the 3D printing compound comprises:

[0072] Iron concentrate: 70-150 parts by weight, preferably 80-140 parts by weight, more preferably 90-...

Embodiment 1

[0094] Take 100 parts of hematite concentrate from Brazil, 1.8 parts of bentonite from India, 0.08 parts of nano-sized titanium dioxide, 0.1 part of micron-sized vanadium pentoxide, 1.6 parts of high elastic modulus polyethylene fiber, and 10 parts of tap water to mix in proportion. Obtain the final mix. Among them, the particle size of a hematite concentrate in Brazil is -0.074mm, which is 92.50%, the water absorption rate of a bentonite in India is 230%, the particle size range of nano-sized titanium dioxide is ≤30nm, and the particle size range of micron-sized vanadium pentoxide is ≤20μm, the average length range of high elastic modulus polyethylene fibers is 14mm, and the elastic modulus is 100N / tex.

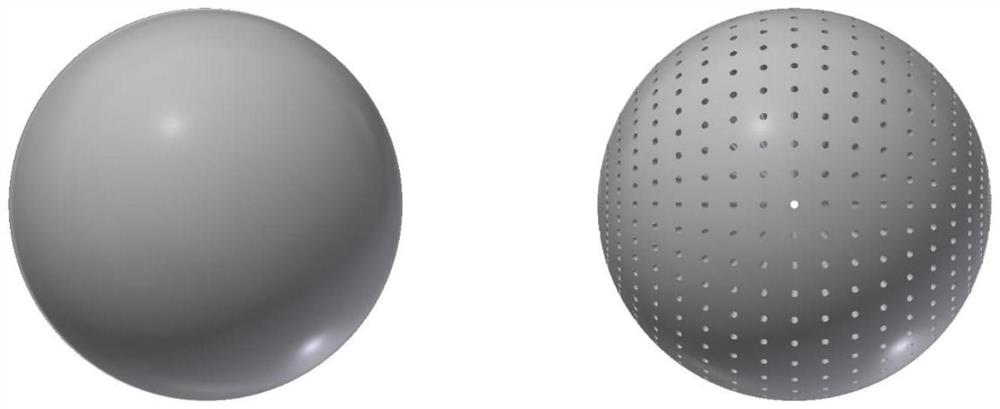

[0095] A comparative test of green pellets obtained by using traditional pelletizing discs and green pellets obtained by 3D printing technology was carried out. The compressive strength is 4.2 times / 0.5m, the compressive strength is 10.4N / piece, and the burst temperature is...

Embodiment 2

[0098] Take 100 parts of a mixture of magnetite in Liaoning and hematite concentrate in Australia (the ratio is 1:1), 2.8 parts of bentonite in Hunan, 0.12 parts of nano-scale titanium dioxide, and 2.4 parts of high elastic modulus polyethylene fiber. part, 0.15 part of micron vanadium pentoxide, and 13.0 parts of tap water were mixed to obtain the final mixture. Among them, the particle size of a magnetite in Liaoning is -0.074mm, which is 95.65%, the particle size of a hematite concentrate in Australia is -0.074mm, which is 93.20%, and the water absorption rate of a certain bentonite in Hunan is 185%. ≤20nm, the particle size range of micron vanadium pentoxide is ≤15μm, the average length of the high elastic modulus polyethylene fiber is 18mm, and the elastic modulus is 120N / tex.

[0099] A comparative test of green pellets obtained by using traditional pelletizing discs and green pellets obtained by 3D printing technology was carried out. is 4.5 times / 0.5m, the compressive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com