A rolling (feconicrr n /al)-2024al composite plate and its preparation method

A composite sheet and composite material technology, applied in the direction of metal rolling, etc., can solve the problems of limited application scope and low ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

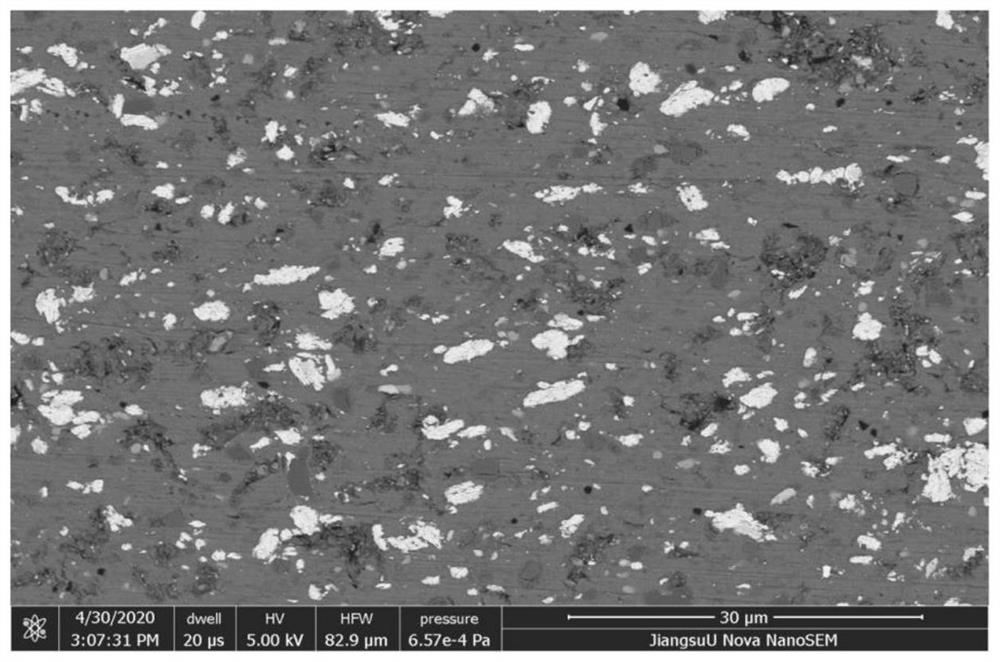

Image

Examples

Embodiment 1

[0029] (1) Preparation of medium entropy alloy powder: the reinforcing base is FeCoNiCrC 0.2 For medium-entropy alloys, according to the ratio of atomic number 1:1:1:1:0.2, calculate and weigh the corresponding mass of powder, put the mixed powder in the ball mill jar, vacuumize and pass in argon, and then high-energy Ball milling for mechanical alloying. The parameters of ball milling are as follows: the mass ratio of ball to material is 12:1, dry milling for 30 hours at a speed of 150 r / min, and then adding absolute ethanol as a process control agent, wet milling for 12 hours at a speed of 300 r / min. Dry for 60h to obtain high entropy alloy powder.

[0030] (2) Preparation of composite powder: the high-entropy alloy powder particles and pure aluminum powder are mixed, and the addition amount of the high-entropy alloy powder particles of the reinforcing phase is 20% by mass fraction. The composite powder is obtained by ball milling with a ball mill, and the ball milling is ...

Embodiment 2

[0036] (1) Preparation of medium entropy alloy powder: the reinforcing base is FeCoNiCrC 0.5 For medium-entropy alloys, according to the ratio of atomic number 1:1:1:1:0.5, calculate and weigh the corresponding mass of powder, put the mixed powder in the ball mill jar, vacuumize and pass in argon, and then high-energy Ball milling for mechanical alloying. The parameters of ball milling are as follows: the mass ratio of ball to material is 12:1, dry milling for 30 hours at a speed of 150 r / min, and then adding absolute ethanol as a process control agent, wet milling for 12 hours at a speed of 300 r / min. Dry for 60h to obtain high entropy alloy powder.

[0037] (2) Preparation of composite powder: the high-entropy alloy powder particles and pure aluminum powder are mixed, and the addition amount of the high-entropy alloy powder particles of the reinforcing phase is 20% by mass fraction. The composite powder is obtained by ball milling with a ball mill, and the ball milling is ...

Embodiment 3

[0043] (1) Preparation of medium entropy alloy powder: the reinforcing base is FeCoNiCrB 0.5 For medium-entropy alloys, according to the ratio of atomic number 1:1:1:1:0.5, calculate and weigh the corresponding mass of powder, put the mixed powder in the ball mill jar, vacuumize and pass in argon, and then high-energy Ball milling for mechanical alloying. The parameters of ball milling are as follows: the mass ratio of ball to material is 12:1, dry milling for 30 hours at a speed of 150 r / min, and then adding absolute ethanol as a process control agent, wet milling for 12 hours at a speed of 300 r / min. Dry for 60h to obtain high entropy alloy powder.

[0044] (2) Preparation of composite powder: the high-entropy alloy powder particles and pure aluminum powder are mixed, and the addition amount of the high-entropy alloy powder particles of the reinforcing phase is 20% by mass fraction. The composite powder is obtained by ball milling with a ball mill, and the ball milling is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com