Annealing furnace and annealing process for copper wire production

An annealing furnace and copper wire technology, applied in the field of annealing furnace and annealing process, can solve the problems of imperfect design of antioxidant cooling circulating water device, imperfect design of vapor protection, affecting production efficiency and quality, etc., so as to improve production efficiency and improve production efficiency. Product qualification rate, reducing surface contamination, small resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

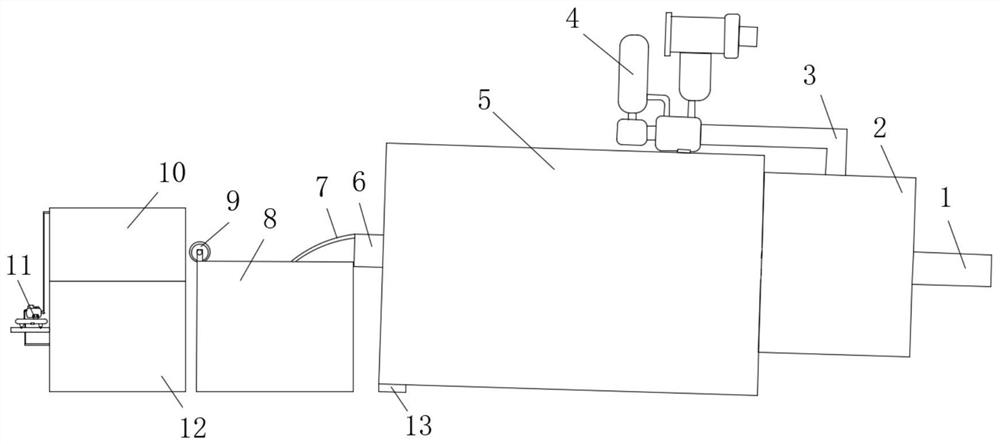

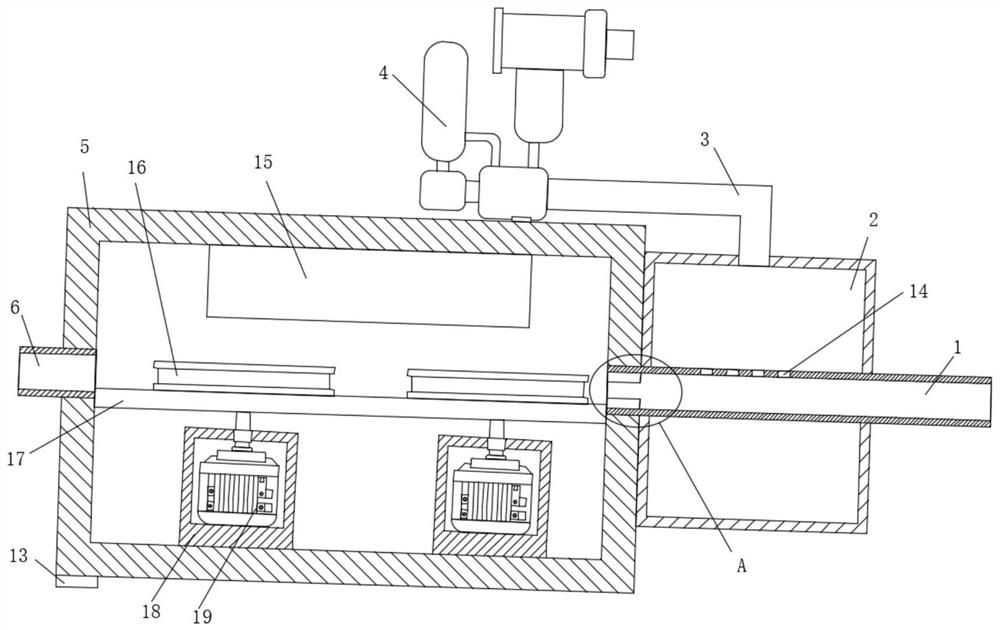

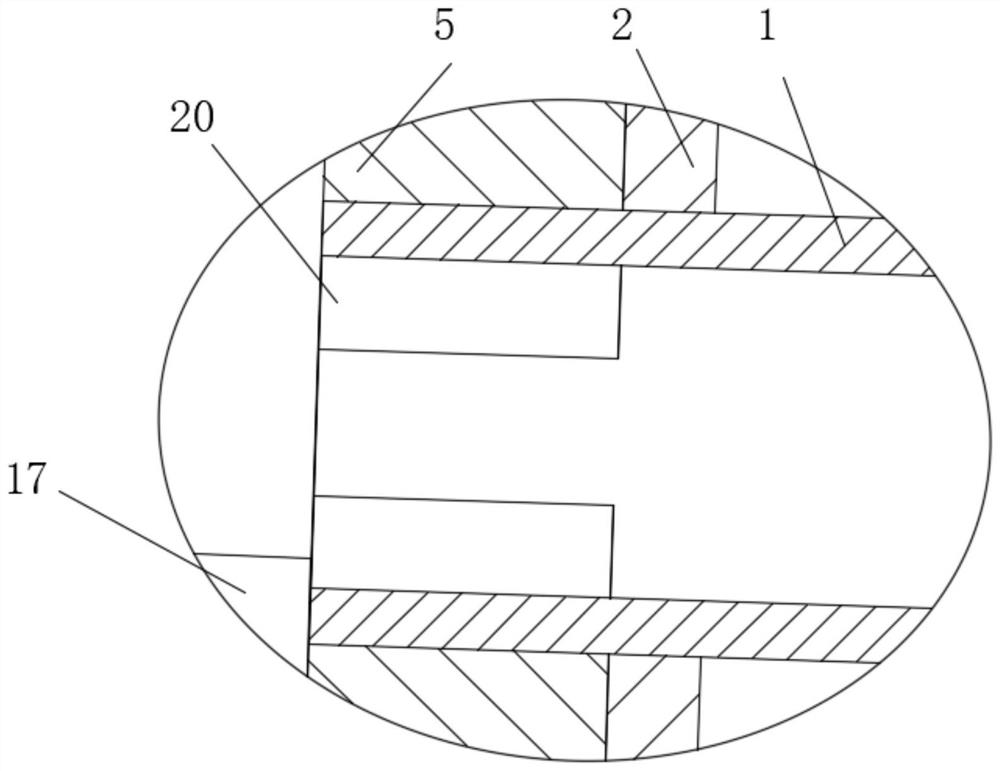

[0038] refer to Figure 1-8 , an annealing furnace for copper wire production, comprising an annealing furnace body 5, a cooling water tank 8, a copper wire 21 and an antioxidant water tank 12, the inside of the annealing furnace body 5 is provided with an annealing assembly for annealing the copper wire 21, One side of the annealing furnace body 5 is provided with a plurality of inlets, and feed pipes 1 corresponding to one of the inlets are provided, and the outside of the feed pipes 1 is provided with the same steam assembly for preventing the copper wire 21 from oxidizing, The side of the annealing furnace body 5 away from the feed pipe 1 is provided with a plurality of outlets, and a discharge pipe 6 corresponding to one of them is arranged in the outlet, and the discharge pipe 6 corresponds to the feed pipe 1 one by one, and the cooling water tank 8 The interior is provided with a cooling assembly for cooling the copper wire 21, the interior of the antioxidant water tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com