Liquid hydrogen and liquid oxygen direct injection piston type internal combustion power system

A technology of liquid hydrogen, liquid oxygen, and power system, which is applied in the direction of fuel system, internal combustion piston engine, charging system, etc., and can solve the problems of high price, consumption of other resources, and impossibility of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

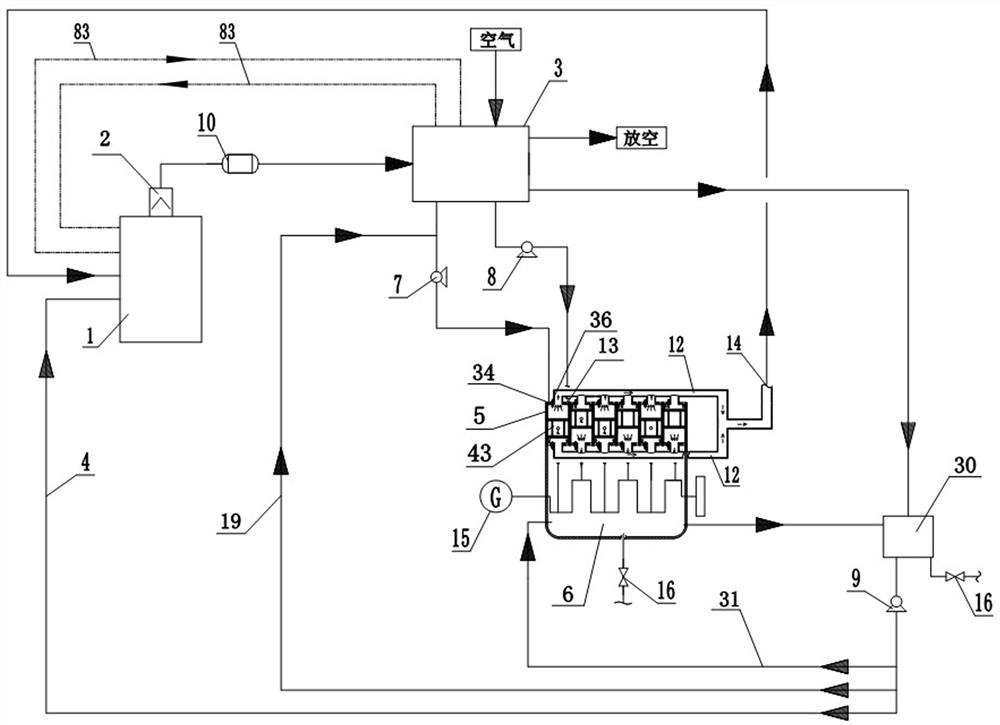

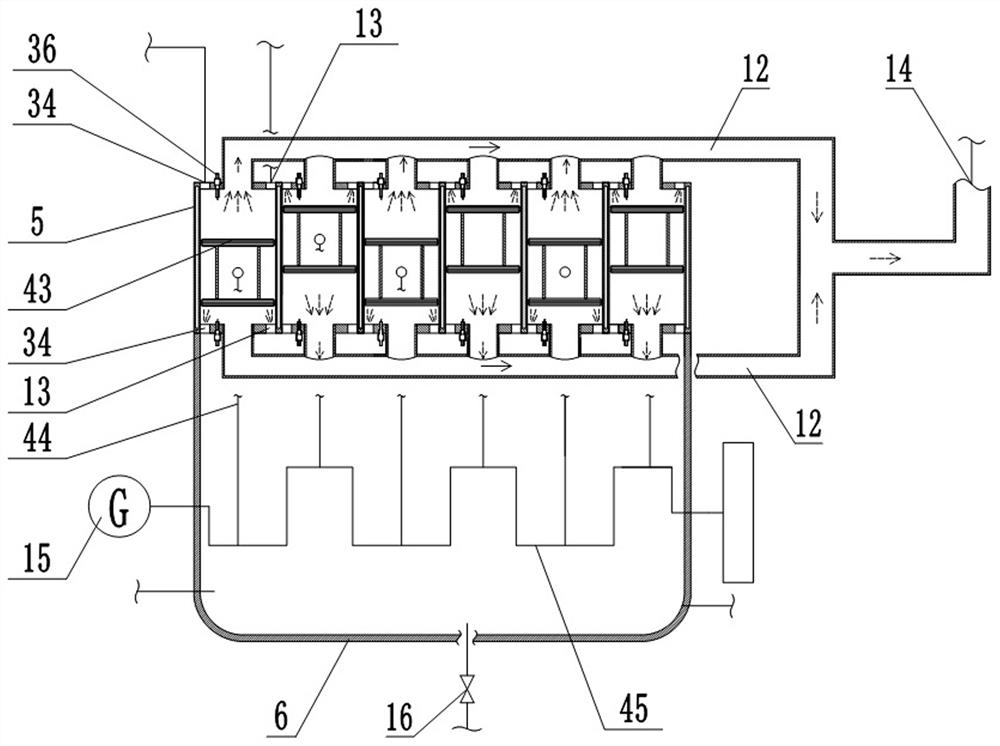

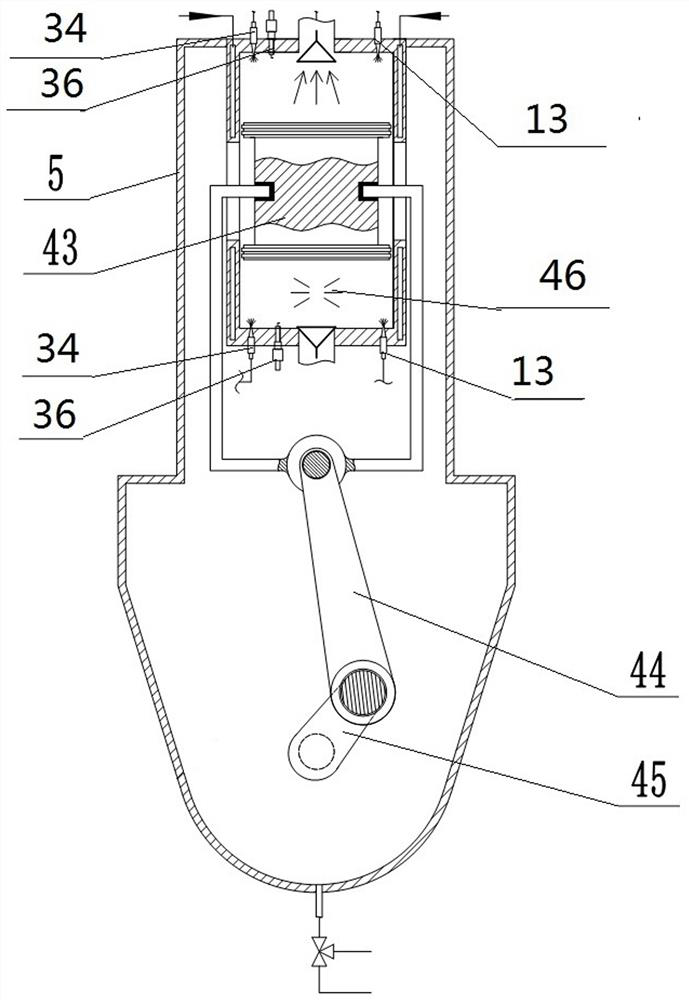

[0053] The embodiment of the present application provides a liquid hydrogen and liquid oxygen direct injection piston type internal combustion power system, such as figure 1 As shown, the system includes: a hydrogen fuel engine, a magnesium hydride storage tank 1 , a Clapp unit 3 , a circulating water tank 30 , a liquid oxygen booster pump 7 , a liquid hydrogen booster pump 8 , a water transfer pump 9 and a low-pressure hydrogen buffer tank 10 .

[0054] The hydrogen outlet of the magnesium hydride storage tank 1 is provided with a hydrogen filter membrane 2 , and the circulating water tank 30 and the water bottom shell 6 of the hydrogen fuel engine are provided with a drain port 16 .

[0055] The hydrogen outlet of the magnesium hydride storage tank 1 is connected to the low-pressure hydrogen buffer tank 10 , and the outlet of the low-pressure hydrogen buffer tank 10 is connected to the Clapp unit 3 . The Clep unit 3 is used for producing liquid hydrogen from the hydrogen dis...

Embodiment 2

[0121] The embodiment of the present application also provides another liquid hydrogen liquid oxygen direct injection piston type internal combustion power system, such as Figure 6 As shown, the system includes: a hydrogen fuel engine, a magnesium hydride storage tank 1, a Collaps unit 3, a circulating water tank 30, a liquid oxygen booster pump 7, a liquid hydrogen booster pump 8, a water delivery pump 9, an oxygen tank 20 and low-pressure hydrogen Buffer tank 10. The hydrogen outlet of the magnesium hydride storage tank 1 is provided with a hydrogen filter membrane 2 , and the circulating water tank 30 is provided with a drain port 16 . The Clep unit 3 is used to prepare liquid hydrogen from the hydrogen discharged from the magnesium hydride storage tank 1 , and to prepare liquid oxygen from the oxygen output from the oxygen tank 20 .

[0122] The hydrogen outlet of the magnesium hydride storage tank 1 is connected to the low-pressure hydrogen buffer tank 10 , and the outl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com