Quasi-solid-state battery pole piece and preparation method and application thereof

A battery pole piece, quasi-solid-state technology, applied in the field of quasi-solid-state battery pole piece and its preparation, can solve the problems of low ionic conductivity of materials, poor rate performance, poor cycle stability and compatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

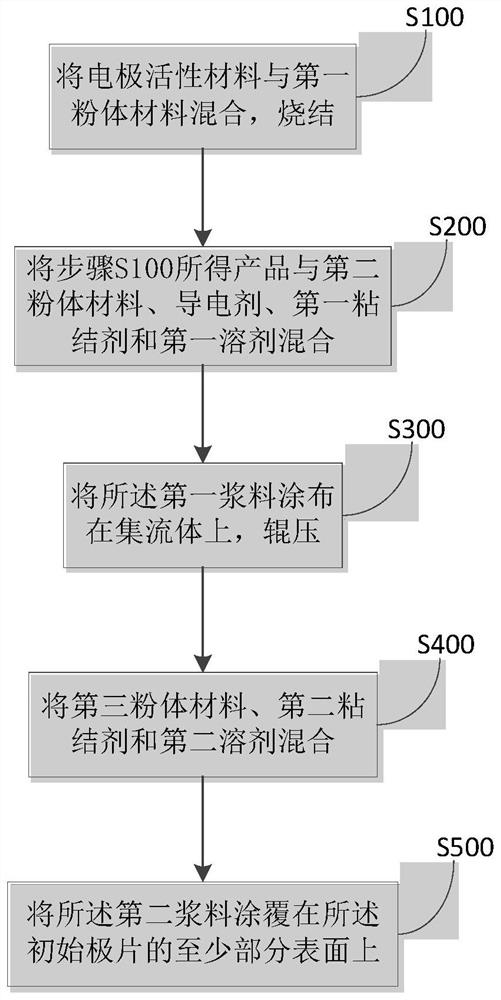

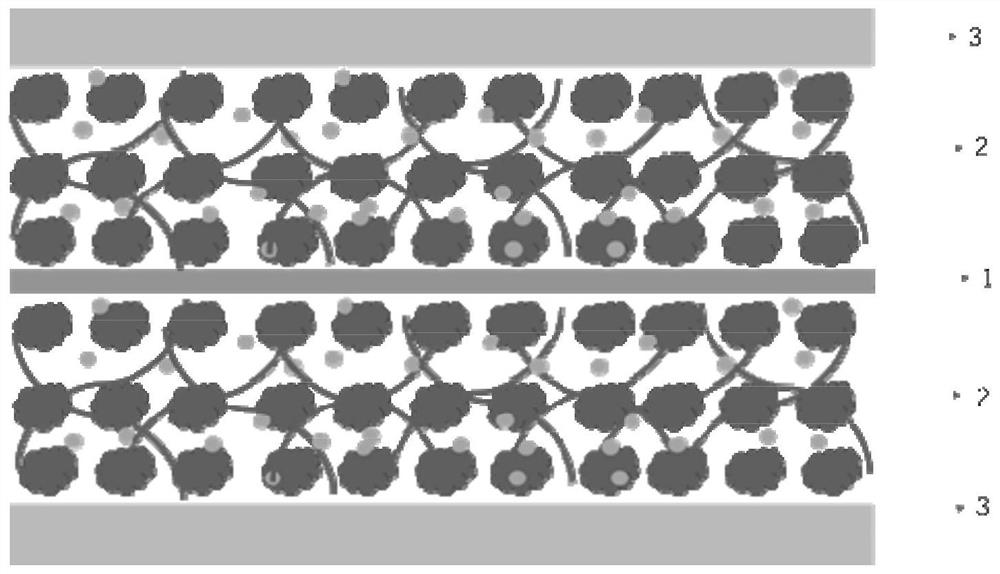

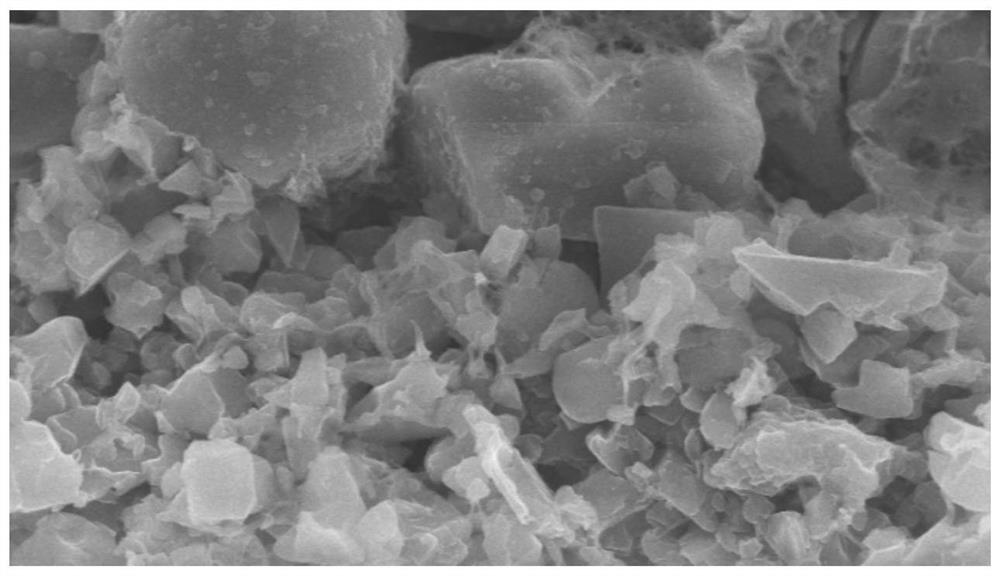

[0082]According to the method for preparing the above-mentioned quasi-solid battery pole piece of the embodiment of the present invention, the electrode active material is mixed with the first powder material, and after sintering, the first powder material melts during the sintering process to form a surface coating layer with a core-shell structure , The first powder material is coated on the surface of the electrode active material by chemical bonding, and the coating layer has a stable structure and low contact resistance. A second powder material is added to the first slurry to form an initial pole piece. The second powder material acts as a solid electrolyte to mainly conduct ions, reduce the interface impedance, and at the same time protect the electrodes from thermal runaway of the battery. A high-porosity composite coating layer is coated on the surface of the initial pole piece, and the composite coating layer includes a third powder material. The main effect of high porosi...

Embodiment 1

[0089]This embodiment provides a method for preparing a quasi-solid battery positive electrode sheet:

[0090]Step 1: Pass the positive electrode active material nickel cobalt manganese oxide lithium with the first powder material (NASICON type electrolyte Li1.3Al0.3Ti1.7(PO4)3) Uniformly mixed, the particle size of the first powder material is less than or equal to 300 nm, and then the first powder material is uniformly coated on the surface of the positive electrode active material by sintering, and the first powder material is formed on the surface of the positive electrode active material The thickness of the cladding layer is 1 nm. The above-mentioned positive electrode active material nickel cobalt manganese lithium and the first powder material (NASICON type electrolyte Li1.3Al0.3Ti1.7(PO4)3The mass ratio of) is 100:4.

[0091]Step 2: Coating the positive electrode active material coated with the first powder material, the second powder material particle powder (Li1.3Al0.3Ti1.7(PO4...

Embodiment 2

[0094]This embodiment provides a method for preparing a quasi-solid battery negative electrode sheet:

[0095]Step 1: The anode active material graphite is uniformly mixed with the first powder material (γ-AlOOH), the particle size of the first powder material is less than or equal to 300nm, and then the first powder material is uniformly coated on the anode active material by sintering. On the surface of the material, the thickness of the coating layer formed by the first powder material on the surface of the negative active material is 10 nm. The mass ratio of the above-mentioned negative electrode active material graphite to the first powder material (γ-AlOOH) is 100:2.

[0096]Step 2: Mix the anode active material coated with the first powder material and the second powder material (γ-AlOOH) uniformly, then add the conductive agent SP, CMC, and deionized water, stir and knead to obtain the primary slurry, add to Ionized water is continuously stirred to adjust the solid content and vis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com