Preparation method of silicon-carbon composite material

A technology of silicon-carbon composite materials and carbon-based materials, applied in nanotechnology for materials and surface science, active material electrodes, electrical components, etc., to achieve good consistency, avoid agglomeration and agglomeration, and uniform carbon layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

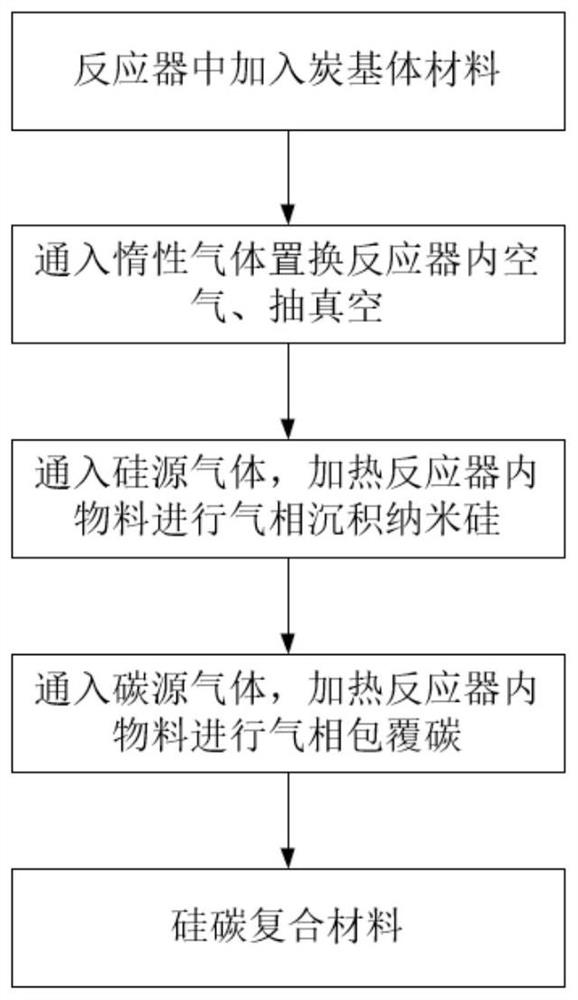

[0051] A method for preparing a silicon-carbon composite material, specifically comprising the following steps:

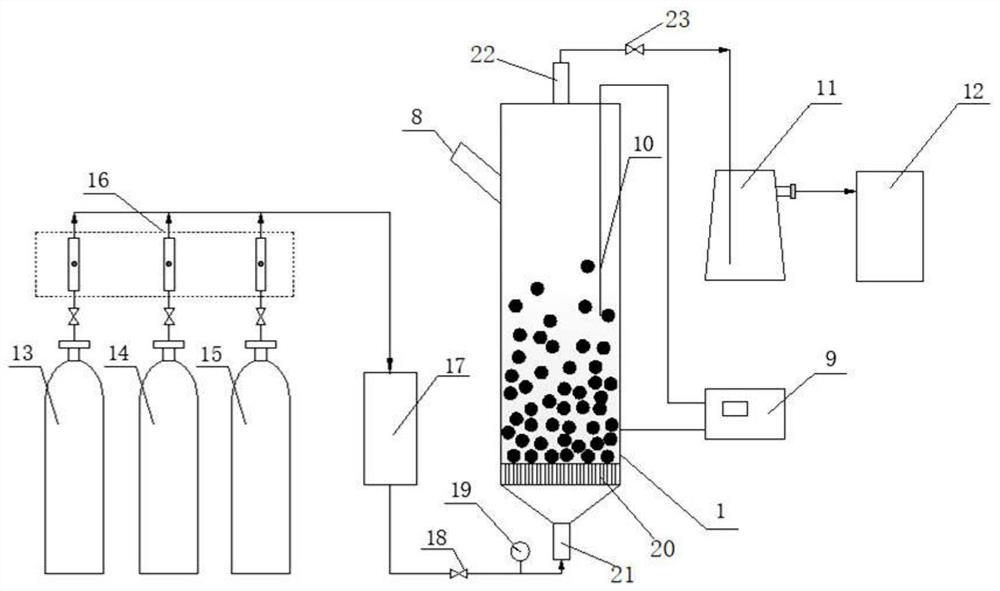

[0052] (1) Place porous artificial graphite in the chemical vapor deposition area of the fluidized bed reactor, pass inert gas to replace the air in the reactor, and evacuate until the reactor pressure is 10Pa;

[0053] (2) Heat the material in the fluidized bed reactor to 500°C, feed silane gas, and conduct vapor deposition reaction for 1 hour, then feed argon gas to fluidize the porous artificial graphite, then close the argon gas, and evacuate to vacuum , the above steps are alternated periodically, repeated 5 times, and the precursor of the silicon-carbon composite material is obtained;

[0054] (3) Heat the material in the fluidized bed reactor to 800°C, pass carbon source gas to the precursor obtained in step (2) for chemical vapor deposition coating carbon, react for 2 hours, pass argon gas to the precursor Fluidized mixing, then turn off the argon gas, a...

Embodiment 2

[0056] A method for preparing a silicon-carbon composite material, specifically comprising the following steps:

[0057] (1) Place porous artificial graphite in the chemical vapor deposition area of the fluidized bed reactor, pass inert gas to replace the air in the reactor, and evacuate until the reactor pressure is 10Pa;

[0058] (2) Heat the material in the fluidized bed reactor to 800°C, feed silane gas, and conduct vapor deposition reaction for 1 hour, then feed argon gas to fluidize the porous artificial graphite, then close the argon gas, and evacuate to vacuum , the above steps are alternated periodically, and repeated 3 times to obtain the precursor of the silicon-carbon composite material;

[0059] (3) Heat the material in the fluidized bed reactor to 1000°C, pass carbon source gas to the precursor obtained in step (2) for chemical vapor deposition coating carbon, react for 1 hour, pass argon gas to the precursor Fluidized mixing, then turn off the argon gas, and ...

Embodiment 3

[0061] A method for preparing a silicon-carbon composite material, specifically comprising the following steps:

[0062] (1) Place porous artificial graphite in the chemical vapor deposition area of the fluidized bed reactor, pass inert gas to replace the air in the reactor, and evacuate until the reactor pressure is 10Pa;

[0063] (2) Heat the material in the fluidized bed reactor to 500°C, feed silane gas, and conduct vapor deposition reaction for 1 hour, then feed argon gas to fluidize the porous artificial graphite, then close the argon gas, and evacuate to vacuum , the above steps are alternated periodically, and repeated 3 times to obtain the precursor of the silicon-carbon composite material;

[0064] (3) The fluidized bed reactor was heated to 800°C, and argon gas was introduced to fluidize the precursor. During the fluidization process, acetylene gas was introduced to conduct vapor phase deposition of carbon, and the reaction was performed for 8 hours to obtain a si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com